An indirect measurement device and calibration method for vehicle operating condition parameters

A technology of vehicle operation and measuring devices, which is applied in the direction of measuring devices, force/torque/work measuring instruments, force/torque/power measuring instruments calibration/testing, etc. Problems such as power and the inability to measure the whole vehicle, to achieve the effect of improving convenience and accurate indirect measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings:

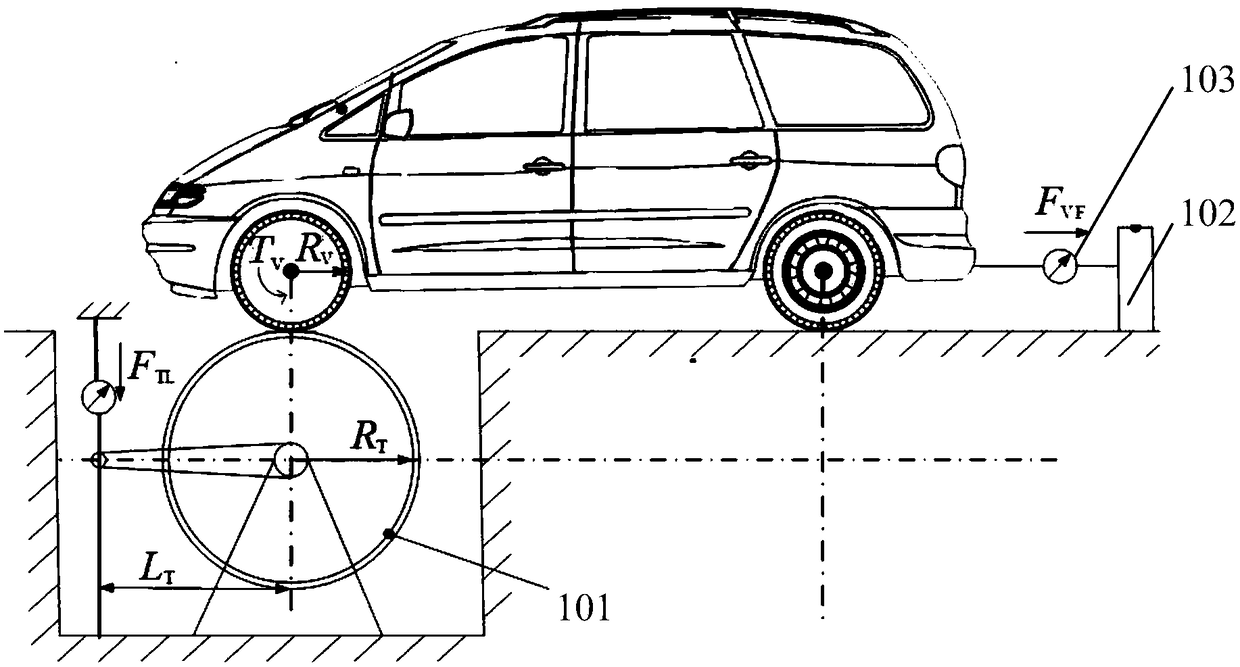

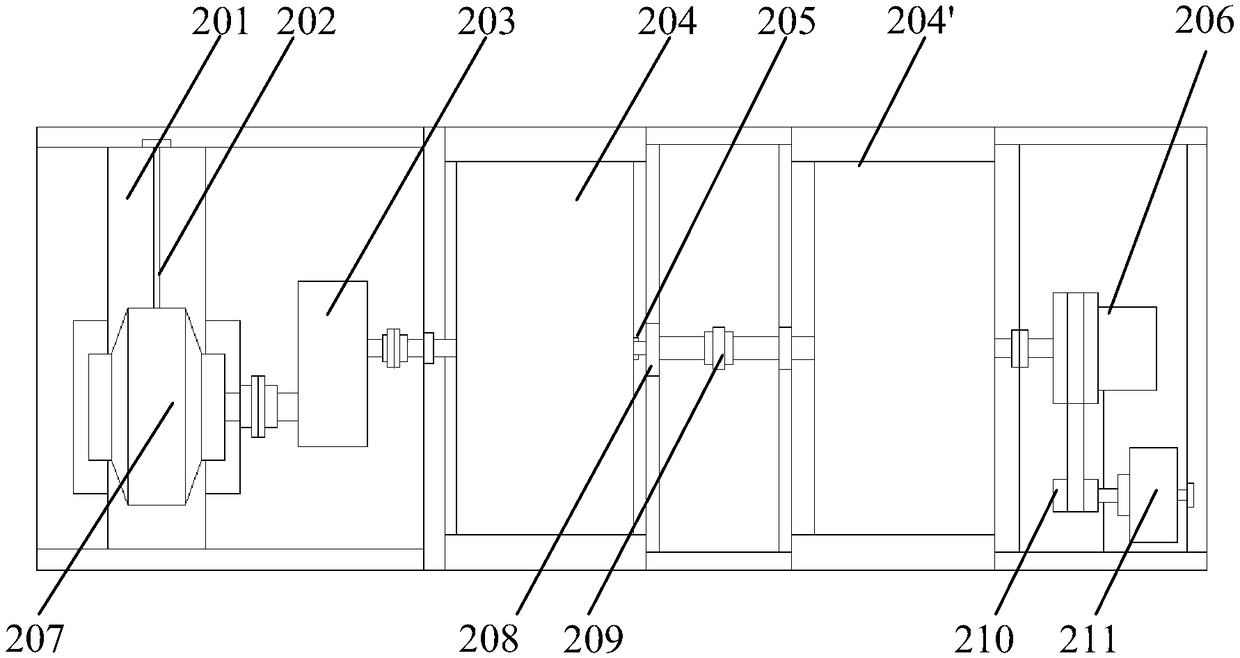

[0027] see figure 1 , the device for indirect measurement of vehicle operating condition parameters in this embodiment includes a chassis dynamometer 101, a rear protective pile 102, and a rear tension sensor 103. The chassis dynamometer 101 is used to contact the wheels of the vehicle to be tested, and the rear protective pile 102 is fixed on On the ground at the rear side of the chassis dynamometer; the rear tension sensor 103 is connected between the rear protective pile 102 and the rear end of the vehicle to be checked through a cable; the protective pile is connected with the tension sensor by a cable to prevent the vehicle from breaking away from the drum.

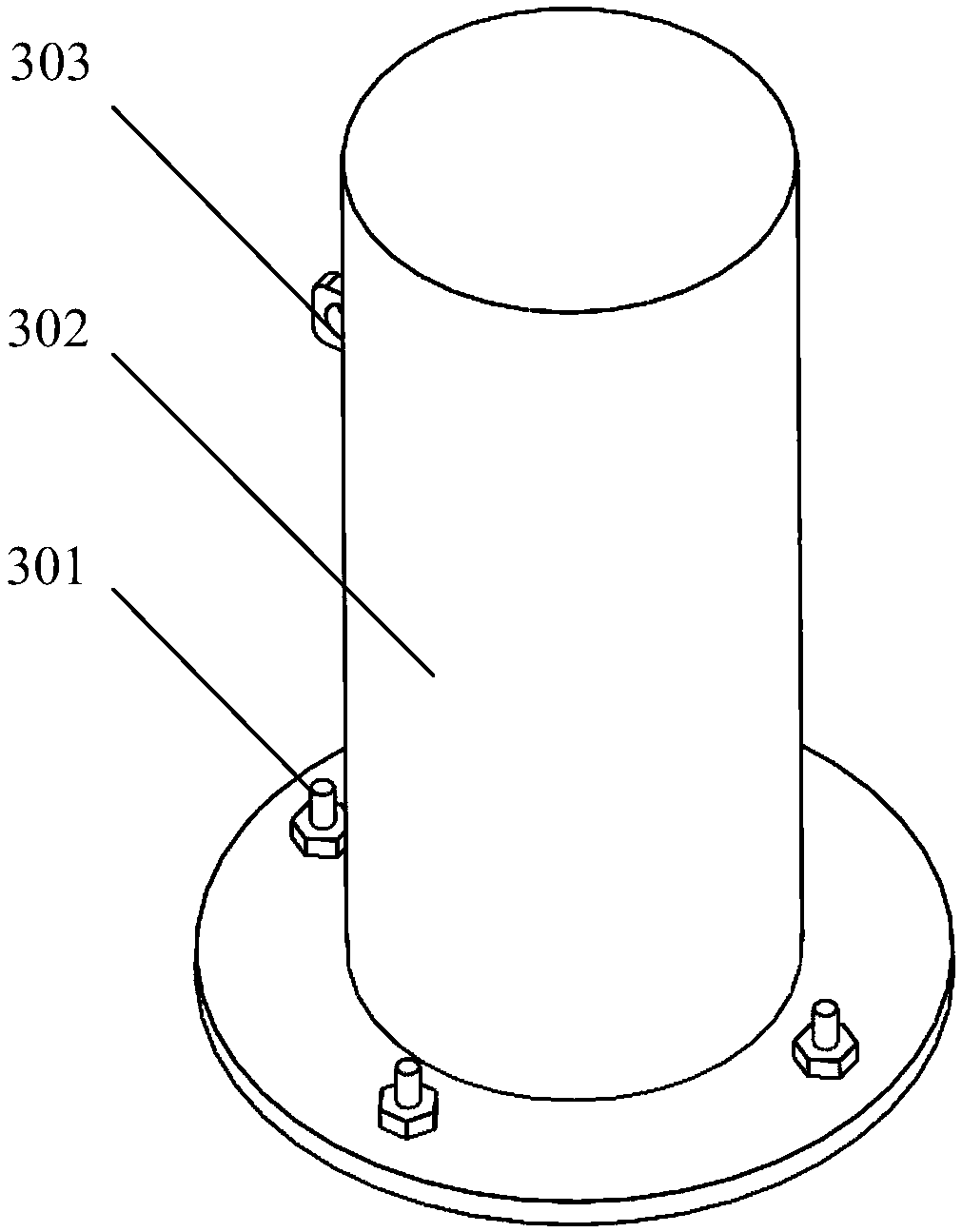

[0028] Such as figure 2 The above two protective piles are all composed of anchor bolts 301, main body 302, and cable holes 303. The anchor bolts 301 fix the protective pile main bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com