Multi-component fiber balance and measurement method thereof

A multi-component, balance technology, applied in measuring devices, fluid pressure measurement using optical methods, measuring fluid pressure, etc., can solve problems such as poor practicability of fiber optic balances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

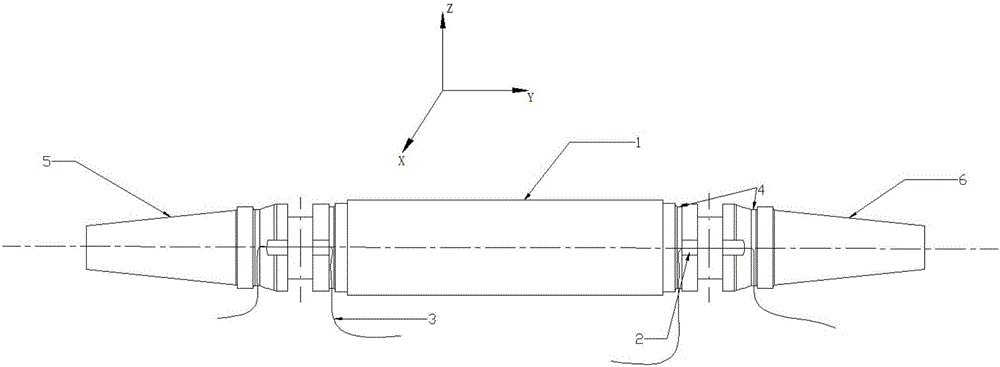

[0039] Example 1. The multi-component optical fiber balance of the present invention includes a balance main body 1, a notch 2, a fiber grating strain gauge 3, a wire groove 4, a support rod end 5 and a fixed end 6. The fixed end 6 is installed on the measuring platform by a fixing device. The balance main body 1 has a square groove in the circumferential direction at the positions close to the fixed end 6 and the supporting rod end 5. The square groove has four notches 2 and a total of eight at both ends. There are two notches 2, and the notches 2 are symmetrically arranged with the same size. The width of the notch is 10mm and the depth is 3mm. A fiber grating strain gage 3 is pasted in the center of each slot 2, a total of eight fiber grating strain gages 3, the lead wire of the fiber grating strain gage 3 is led out by the wire slot 4, and the length of the slot 2 is not less than the length of the grating area of the fiber grating. Then the fiber is pre-stretched, the p...

Embodiment 2

[0040] Example 2. The specific steps of the measurement method of the multi-component fiber balance described in embodiment 1 are as follows:

[0041] Step 1. Fix the fixed end of the fiber optic balance on the measuring platform, and use the end of the support rod to load the load.

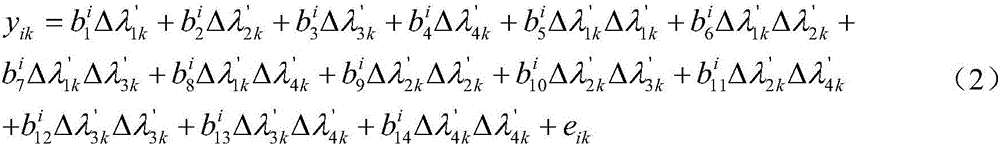

[0042] Step 2. Place one end of the fiber grating strain gauge freely, and fused the other end with the fiber jumper through the fiber fusion splicer. The fiber jumper transmits the optical signal and is input to the terminal fiber demodulator. The fiber grating demodulator has a built-in laser light source. The light source emits broad-spectrum light, which is transmitted to the grating area from the fiber jumper and fiber pigtail. The light of the wavelength that meets the conditions of the Bragg formula is reflected and transmitted through the fiber pigtail and fiber jumper. To the fiber grating demodulator, the fiber grating demodulator responds to the received optical signal as a wavelength valu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com