A rapid layout method for rectangular workpieces for single-size plates

A single-specification, workpiece technology, applied in the field of rapid layout of rectangular workpieces, can solve the problems of poor overall utilization of plates, tools can only travel in a straight line, and high utilization of plates, so as to achieve high utilization of plates, improve utilization of plates, and improve the utilization of plates. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

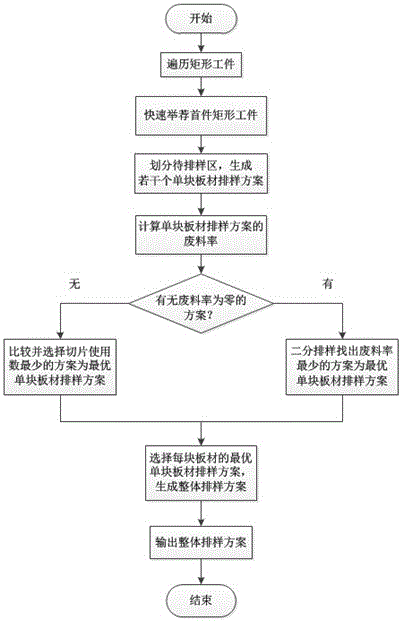

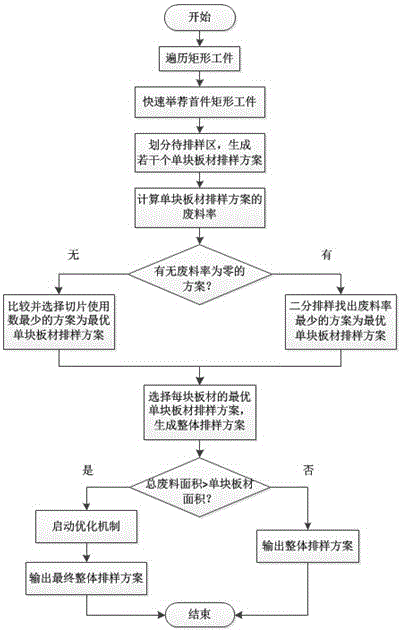

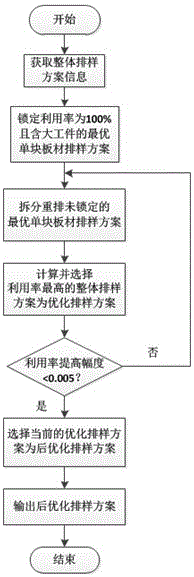

[0059] The method for fast nesting of rectangular workpieces facing single-size plates in this embodiment, such as figure 1 shown, including the following steps:

[0060] Step 1, the step of traversing workpieces, input the initial data of several rectangular workpieces to be discharged, and traverse the initial data of all rectangular workpieces to be discharged;

[0061] Step 2, the step of laying out the first rectangular workpiece, quickly recommending a piece of the rectangular workpiece as the first rectangular workpiece, and discharging, the first rectangular workpiece is discharged according to the priority of the lower left, lower right, upper left or upper right, and the The first rectangular workpiece is placed in the lower left corner, lower right corner, upper left corner or upper right corner of the rectangular single plate;

[0062] Step 3, the step of dividing the area to be laid out, cutting the single plate along the long side or short side of the first rect...

Embodiment 2

[0115] Test the method for rapid layout of rectangular workpieces facing single-size plates in Example 1, and design 21 sets of test case sets. The specifications and quantities of the rectangular workpieces in each set of test case sets are different, and the specifications of the single plate are also different. , test the rapid layout method for rectangular workpieces facing single-size plates in this embodiment, corresponding to the quantity of the single plate that needs to be used in each group of test case sets, the utilization rate and the layout time of the overall layout plan, the test results As shown in Table 1:

[0116]

[0117]

[0118]

[0119]

[0120] Table 1

[0121] As shown in Table 1, all 21 sets of test cases can find the optimal solution with a utilization rate of 100%, indicating that the method for fast layout of rectangular workpieces for single-size sheets can quickly find the optimal solution for the test cases. It has good climbing cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com