Lithium battery power assembly cooling system

A heat dissipation system and electric power technology, applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems of life reduction, explosion, etc., and achieve the effect of improving cooling effect and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1, in the process of manufacturing the temperature equalizing component 2, it is necessary to consider the deformation and expansion caused by the heating process of the battery core 1, and comprehensively utilize the deformation to achieve the purpose of effectively controlling the temperature rising process.

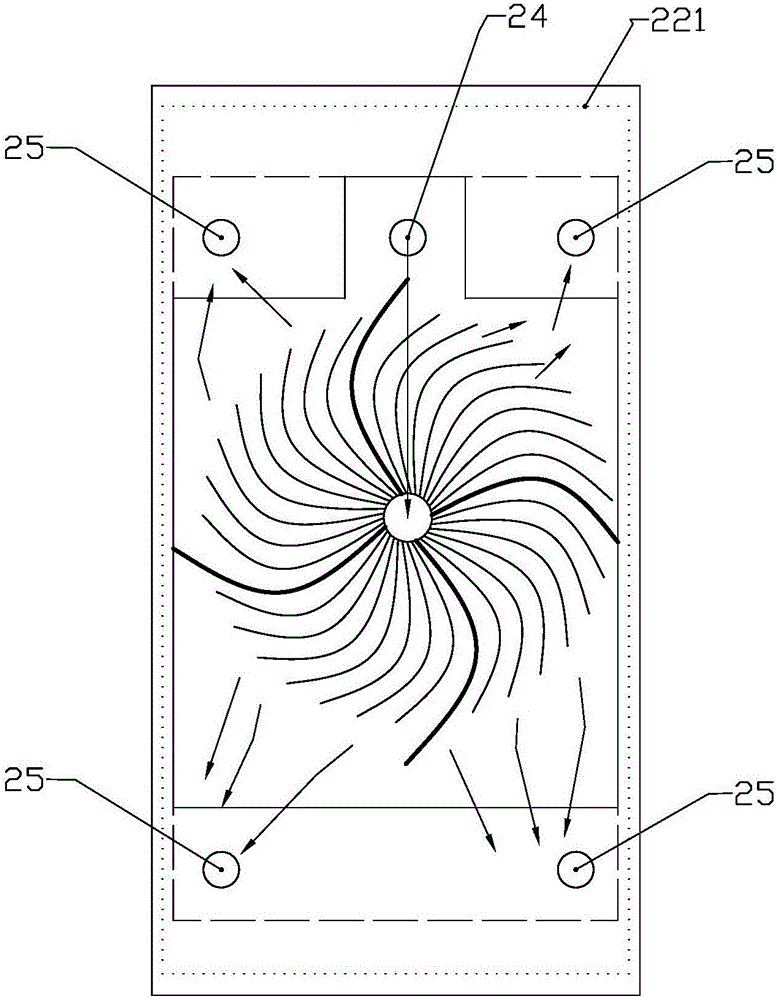

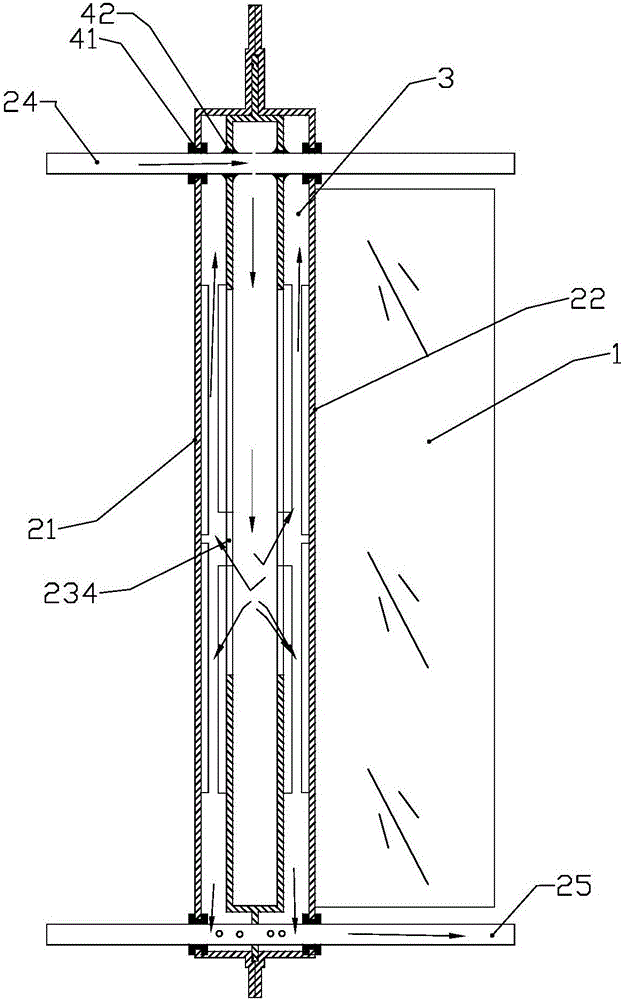

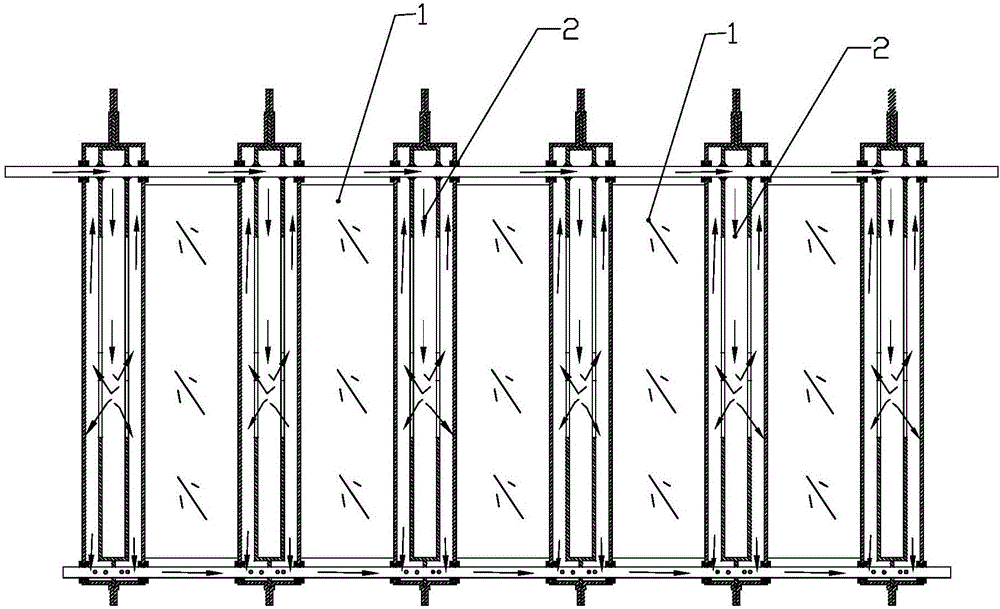

[0051] The temperature uniform assembly 2 includes a left housing 21, a right housing 22, a liquid guide piece 23, a liquid inlet pipe 24, and a liquid outlet pipe 25, wherein the left and right housings are symmetrical structures, and are integrally formed by buckling and surrounding welding , to form a complete shell, and take the left shell 21 as an example to describe in detail, the left shell 21 is stamped from a thin plate made of stainless steel, and is designed as an outwardly convex structure 211, which is used to cooperate with the liquid guide sheet. refer to Figure 5 , and a groove 212 for clamping the battery core is provided on the oute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com