Main shaft grounding device

A technology of grounding device and spindle, which is applied in the direction of connection, conductive connection, vehicle connector, etc., can solve the problems of low grounding reliability, and achieve the effects of high conductivity reliability, improved conductivity reliability, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

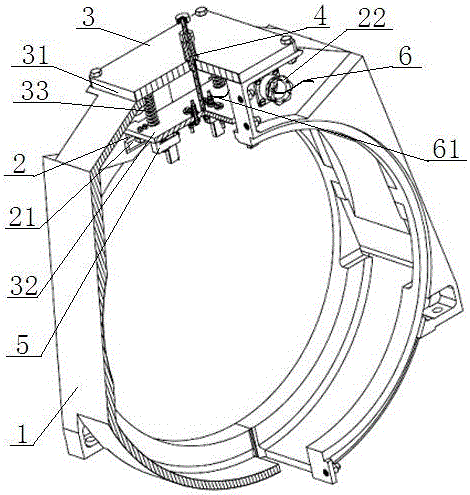

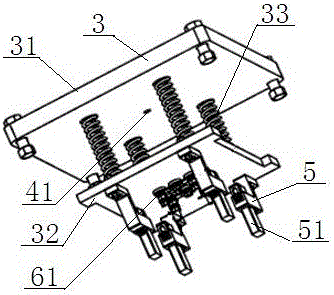

[0044] see Figure 1 to Figure 5 , a main shaft grounding device, comprising a main shaft and a housing 1, the housing 1 is sheathed outside the main shaft, the housing 1 is provided with a main shaft grounding device 3; the main shaft grounding device 3 includes a fixed plate 31 and a movable plate 32, the fixed plate 31 is fixedly connected with the housing 1, the bottom surface of the fixed plate 31 is connected with the top surface of the movable plate 32 through three expansion springs 33 arranged in parallel, and the bottom surface of the movable plate 32 is provided with three A carbon brush holder 5, a carbon brush 51 is fixed inside the carbon brush holder 5, the bottom of the carbon brush 51 is in contact with the outer surface of the main shaft, and the top of the carbon brush 51 is connected with the grounding wire 6; The top of the housing 1 is provided with the installation position 2 of the grounding device, the top of the installation position 2 is fixedly conn...

Embodiment 2

[0046] Described embodiment 2 is substantially the same as embodiment 1, and its difference is:

[0047] The bottom surface of the fixed plate 31 is connected with the top surface of the movable plate 32 by four expansion springs 33 arranged in parallel. Four carbon brush holders 5 are arranged on the bottom surface of the bottom surface, and the installation positions of the four carbon brush holders 5 are located on the four endpoints of the rectangle; the carbon brushes 51 are arranged perpendicular to the horizontal direction.

Embodiment 3

[0049] Described embodiment 3 is substantially the same as embodiment 2, and its difference is:

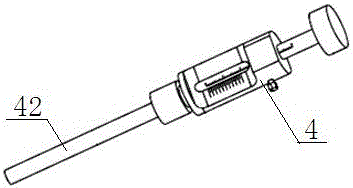

[0050] see figure 2 , the top of the fixed plate 31 is provided with a wear gauge 4, the middle part of the fixed plate 31 is provided with a through hole 41, the measuring rod 42 of the wear measuring gauge 4 is slidingly fitted with the through hole 41, and the measuring rod 42 set vertically to the horizontal direction; a rope guide 22 is provided on the side wall of the installation position 2, and a ground wire through hole 23 is opened on the side wall, and the ground wire 6 is connected to the carbon brush 51 after passing through the ground wire through hole 23, The ground wire through hole 23 is sealed and matched with the ground wire 6; the middle part of the movable plate 32 is provided with a plurality of conductive terminals 61, and the top of the conductive terminal 61 is connected with the ground wire 6. The bottom of 61 is connected with the conductive copper wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com