Conductive material and connecting structure

A technology of conductive materials and conductive particles, applied in conductive materials, conductive materials, conductors, etc., can solve problems such as reduced conductivity reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

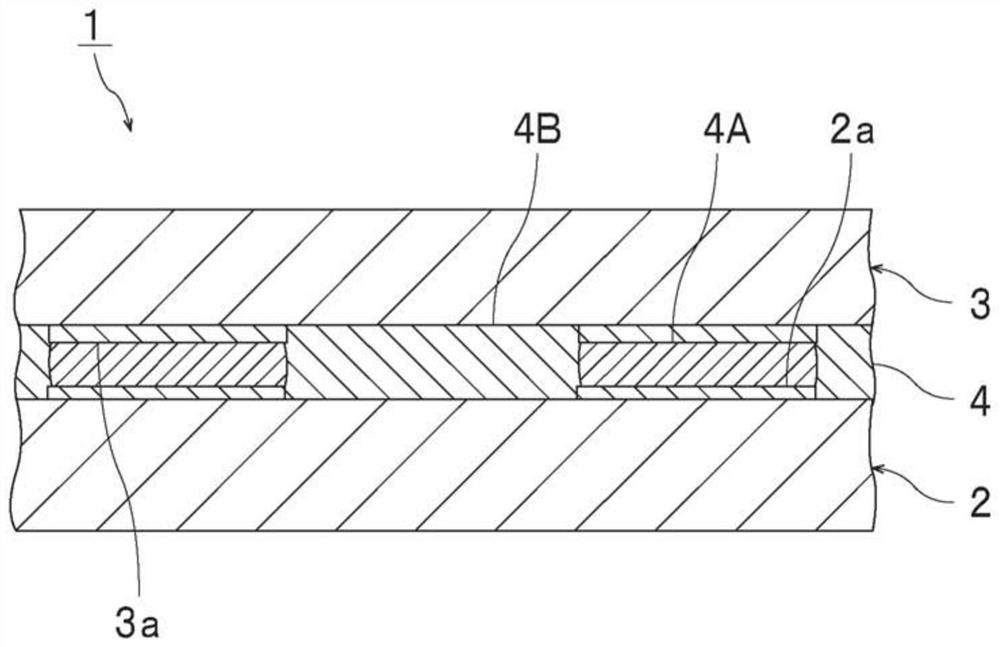

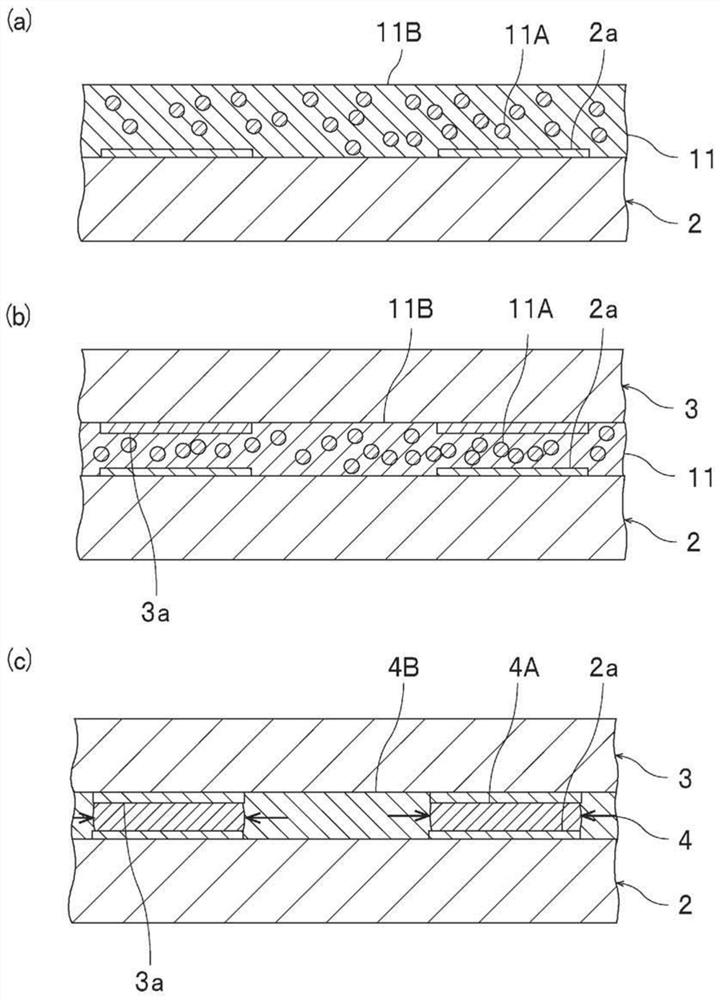

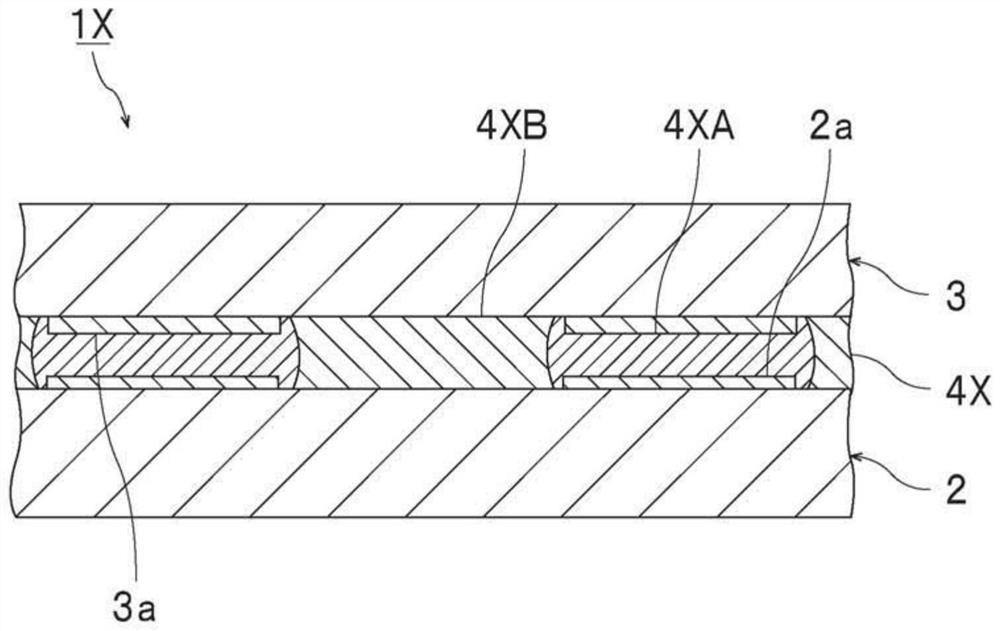

Image

Examples

Embodiment 1~17 and comparative example 1~2

[0299] (1) Preparation of anisotropic conductive paste

[0300] The components shown in the following Table 1 and Table 2 were compounded in the compounding quantities shown in the following Table 1 and Table 2, and the anisotropic conductive paste was obtained. In the obtained anisotropic conductive paste, the flux was present in the states shown in Tables 1 and 2.

[0301] (2) Fabrication of connection structure (array)

[0302] The following semiconductor chip was prepared as the first connection target part: Copper electrodes with a diameter of 250 μm and a thickness of 10 μm were arranged in an array on the surface of the semiconductor chip body (5×5 mm in size and 0.4 mm in thickness) at a pitch of 400 μm. The number of copper electrodes was 10×10 per semiconductor chip, 100 in total.

[0303] Prepare the following glass epoxy substrate as the second connection object part: On the surface of the glass epoxy substrate main body (size 20×20mm, thickness 1.2mm, material F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com