Flush circuit board and manufacturing method thereof

A production method and flush line technology, which are used in chemical/electrolytic methods to remove conductive materials, printed circuit components, and secondary processing of printed circuits, etc., can solve the problem that the circuit board cannot meet the plane contact conduction, and the protection reliability is poor. and other problems, to achieve the effect of excellent flat performance, high electrical conductivity and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

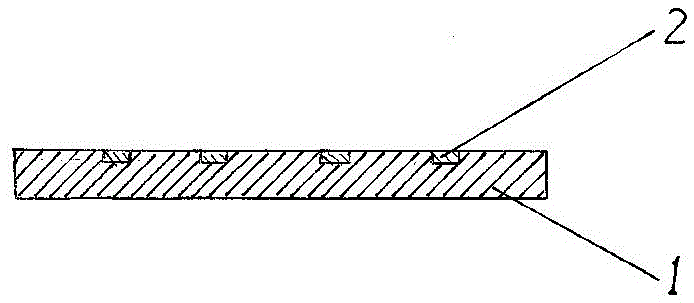

[0029] Such as figure 1 As shown, the flush circuit board of the present invention is provided with a conductive circuit pattern strip 2 on the insulating substrate 1, and the circuit pattern strip 2 is embedded in the upper surface of the insulating substrate 1, and the outer surface of the circuit pattern strip 2 is in contact with the The upper surfaces of the insulating substrate 1 are on the same plane.

[0030] The circuit graphic strip 2 is formed by thermally pressing the conductive copper foil layer bonded on the insulating substrate 1, after surface filming, circuit pattern transfer, etching and fading, and nickel-plating and gold-plating. embedded in the surface of the insulating substrate.

[0031] The circuit pattern strip 2 in the present invention is completely embedded in the interior of the insulating substrate 1, and the surface of the line has conductivity, which meets the requirements of surface contact and conduction. The biggest difference from the tradi...

Embodiment 2

[0033] The manufacturing method of flush circuit board of the present invention comprises the following steps:

[0034] 1. Material cutting: according to the product design requirements, use a cutting machine to cut the prepreg for circuit board production into the required size.

[0035] Precautions for prepreg preparation:

[0036] ①In a clean and dust-free environment, cut the roll material into strips, and then cut them into individual pieces with a paper cutter. The size is enlarged by 10mm according to the length and width of the single blank.

[0037] ②If there are defects such as broken fibers, large particles of jelly, and impurities on the prepreg, they should be removed. Clean spun gauze gloves should be worn during operation, and hand sweat and oil pollution are strictly prohibited.

[0038] ③ When cutting the prepreg, wear a mask to avoid inhaling resin powder. It is advisable to wear long shirts and trousers to avoid itching or allergies caused by resin powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com