An improved electrical connector

An electrical connector, an improved technology, applied in conductive connections, connections, circuits, etc., can solve problems such as insufficient strength, achieve low R&D costs, meet strength requirements, and increase the effect of cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

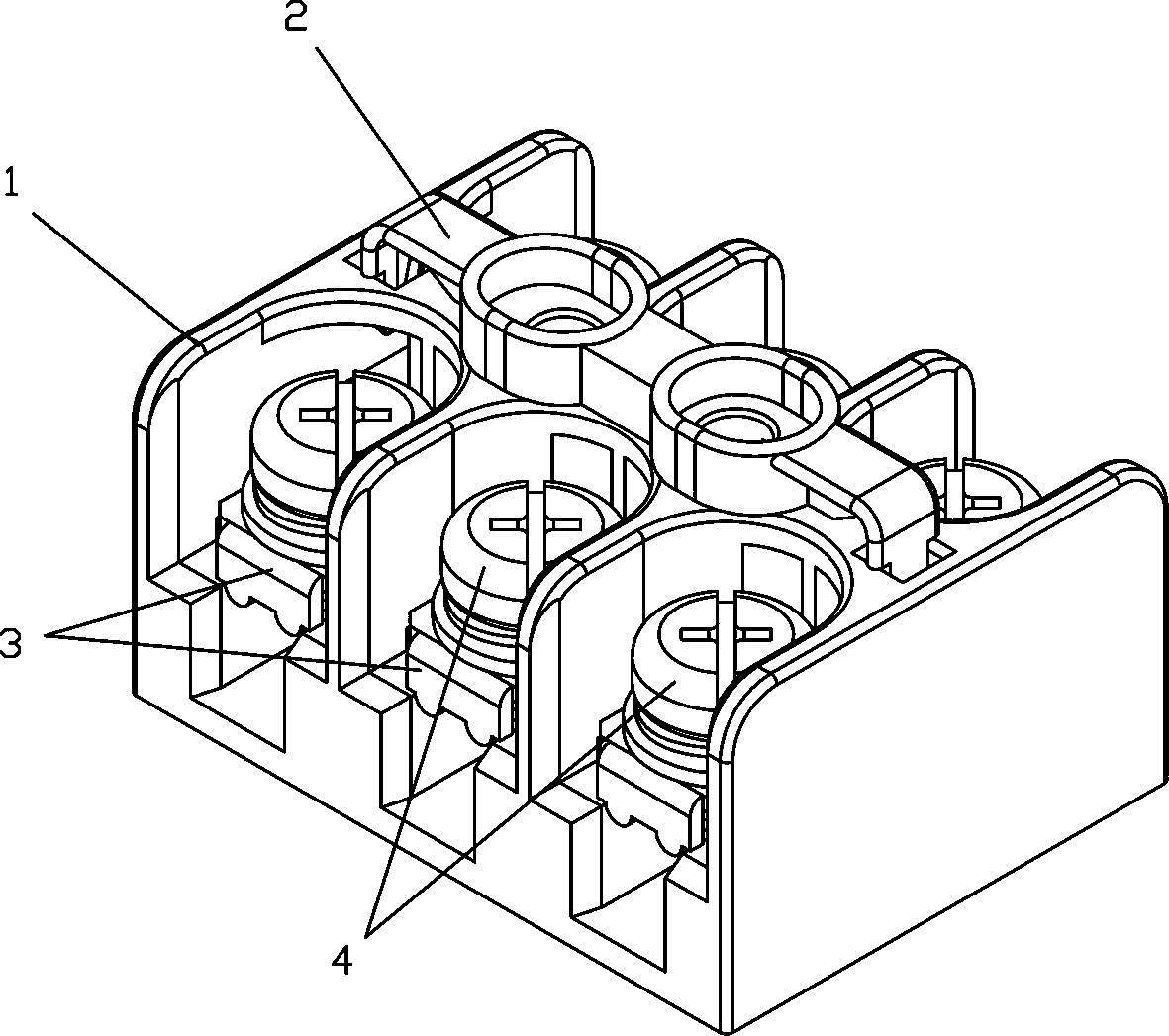

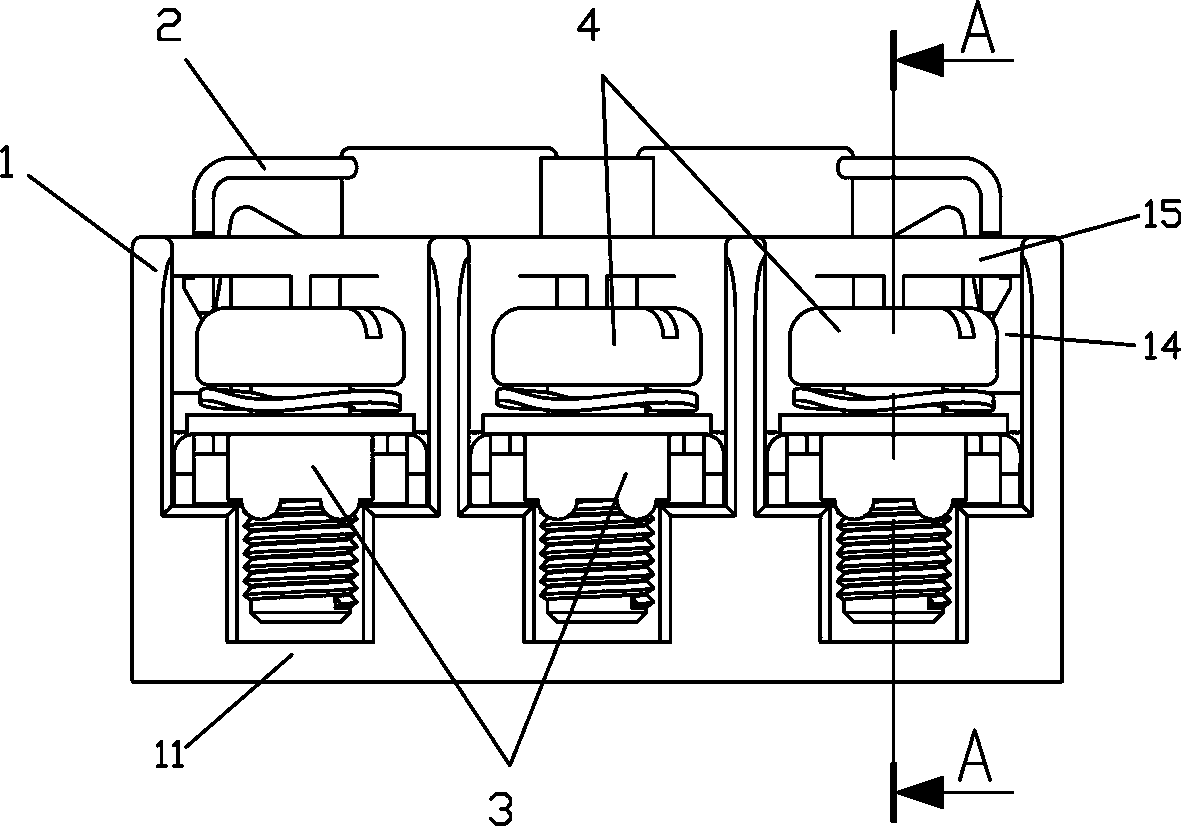

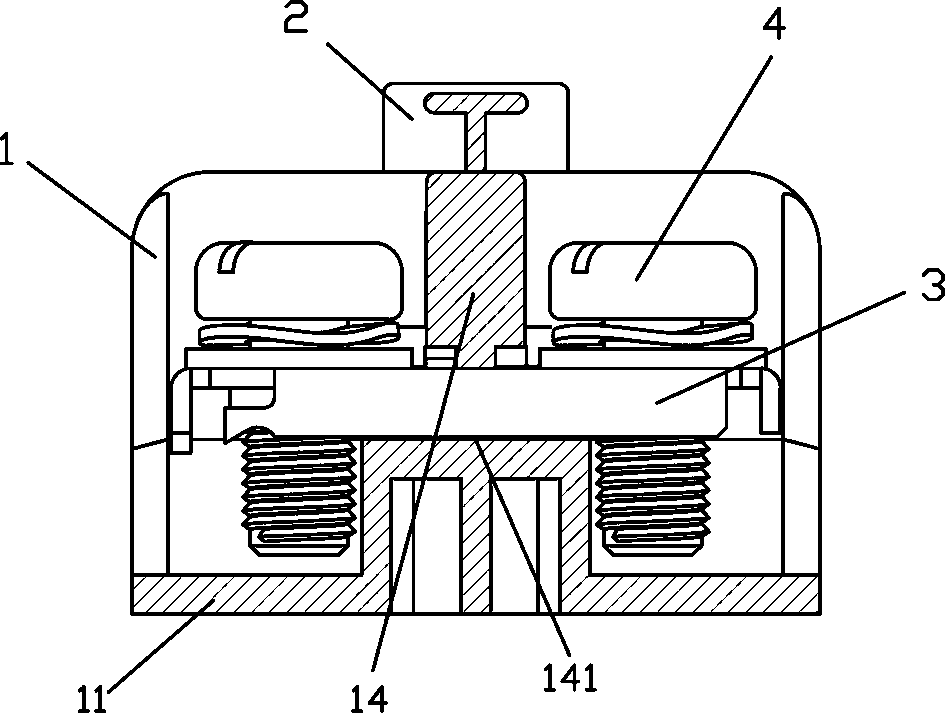

[0028] see Figure 1 to Figure 12 , an improved electrical connector of the present invention, which includes,

[0029] Insulating base 1, comprising,

[0030] Base plate 11, on which four longitudinal partitions 12, 12' are arranged side by side at intervals, and three parallel and independent compartments 13 are formed on the base plate 11 along the length direction (taking compartment 13 as an example, the same below), inside compartment 13 Inner support blocks 131, 132 on both sides;

[0031] A transverse partition 14 is plugged into the middle of the longitudinal partitions 12, 12', and divides the compartment 13 into several corresponding power supply side chambers and load side chambers along the width direction of the bottom plate; the transverse partition 14 is located at The middle part of each chamber is provided with a through hole 141 passing through the front and back;

[0032] A top plate 15 is connected to the top of each of the longitudinal partitions 12, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com