Intravenous needle handle discharging device

A technology of discharging device and venous needle, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of no research on venous needle, low assembly efficiency, difficulty in feeding and assembling, etc., and achieve precise clamping. Reliable, stable, neat clamping force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

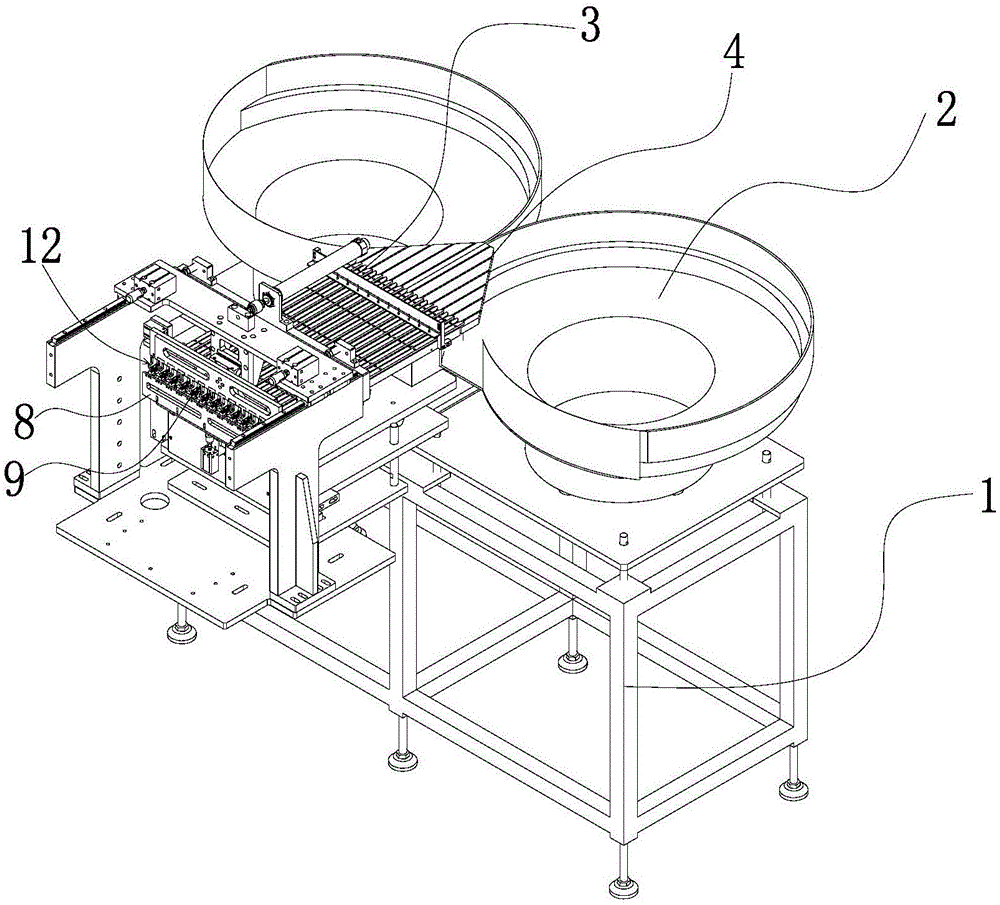

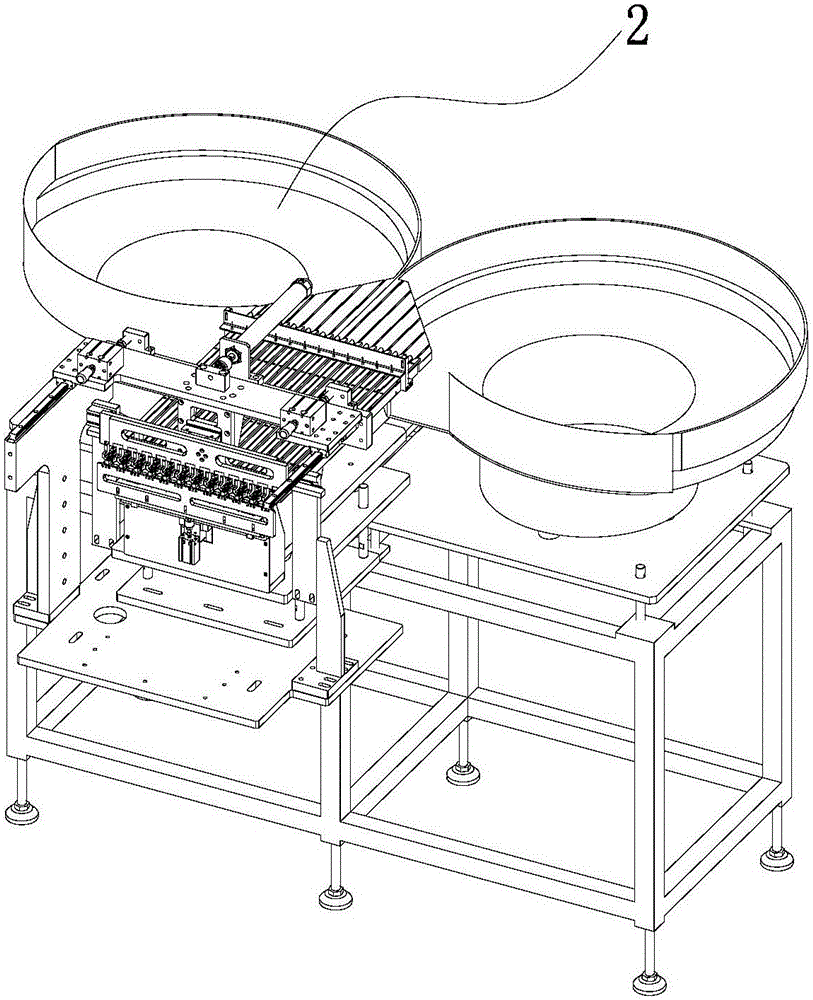

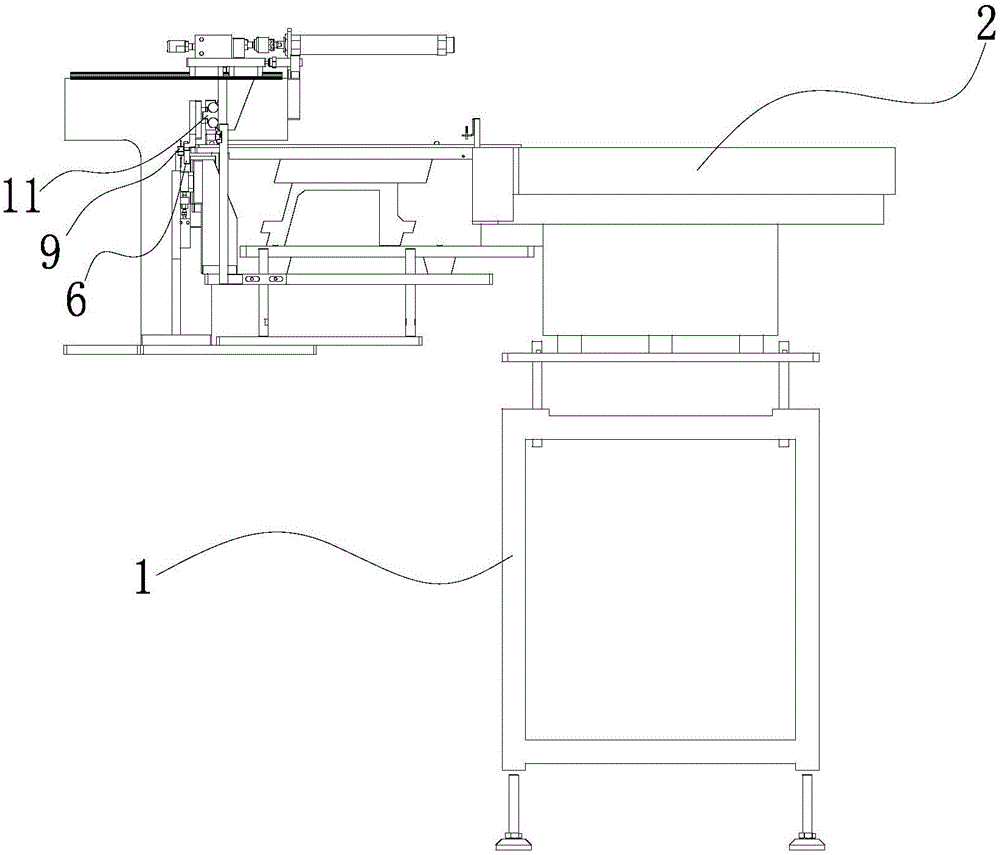

[0029] Example: such as Figure 1-3 As shown, a needle shaft discharge device for venous needles includes a frame 1, a feeder 2 and a delivery channel 3 for conveying the needle handle, the feeder 2 has one or a group of output ports 4, and the The feeder 2 is fixed on the frame 1 and can transport the needle handles to the conveying channel 3 in a unified direction along the output port 4 in an orderly manner. It is characterized in that the discharge device includes a positioning plate 6 and a limit device , the positioning plate 6 and the limiting device are sequentially arranged at the end of the conveying channel 3, driven by the driving device to move up and down, the positioning plate 6 is provided with one or a group of positioning holes 7 capable of accommodating the needle handle, The needle shank abuts against the limiting device through the positioning hole 7 along the delivery channel 3 , and the frame 1 is also provided with a material transfer mechanism capable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com