3D printing die and printing method thereof

A 3D printing and mold technology, applied in the field of 3D printing, can solve the problems that affect the production success rate, model damage, and difficult separation of the model body, and achieve the effects of avoiding damage such as fracture and wear, easy operation, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

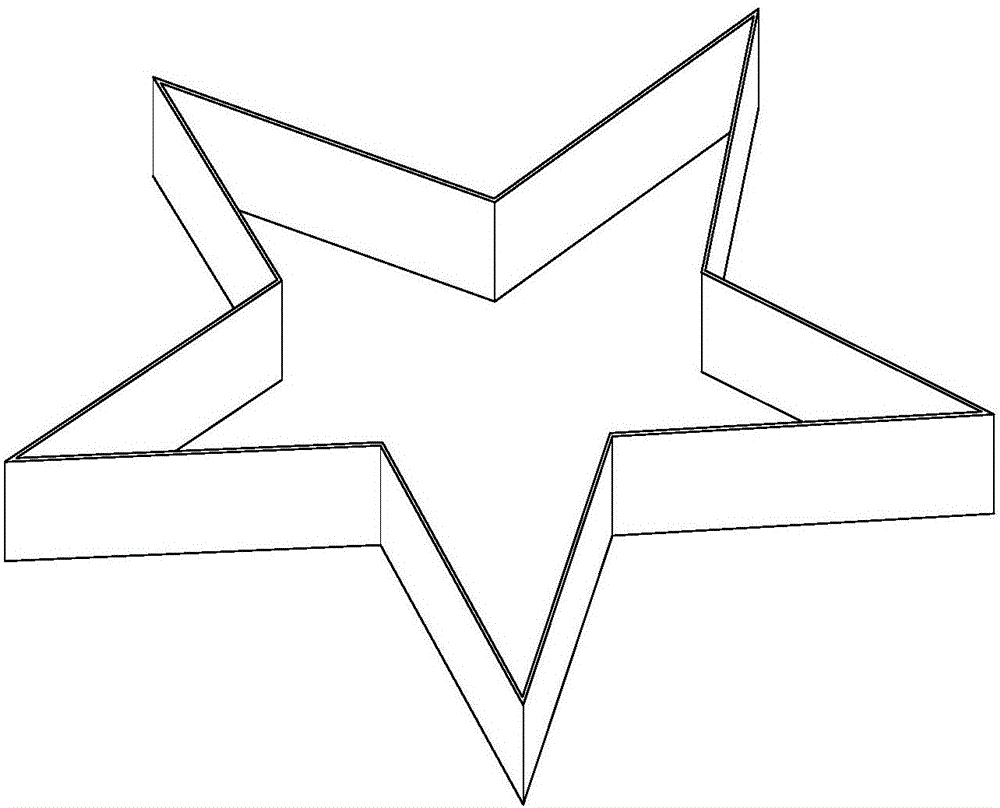

[0029] First of all, it should be noted that the present invention not only provides a 3D printing mold, but also provides a printing method for the 3D printing mold. in figure 1 model shown in figure 2 slices shown in and image 3 The shape of the 3D printing mold shown in the figure is only schematic and does not represent the actual shape of the 3D printing mold of the present invention. In specific applications, the shape of the 3D printing mold of the present invention is determined according to the outline of the actual model. like Figure 1 to Figure 3 A specific embodiment of a 3D printing mold of the present invention is shown. The mold is a single-layer frame body arranged along the contour of the model, wherein the thickness of the single-layer frame body is 0.2-1 mm.

[0030] As a specific embodiment, in a specific printing production process, the printing trajectory path of the single-layer frame body of the 3D printing mold only includes the scanning path gen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com