Exhaust Gas Passage With Aftertreatment System

A technology of exhaust post-treatment and exhaust flow, which is applied in the direction of electronic control of exhaust treatment devices, exhaust devices, exhaust treatment, etc., can solve the problem that the maximum temperature cannot be exceeded, and achieve the effect of ensuring rapid response behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

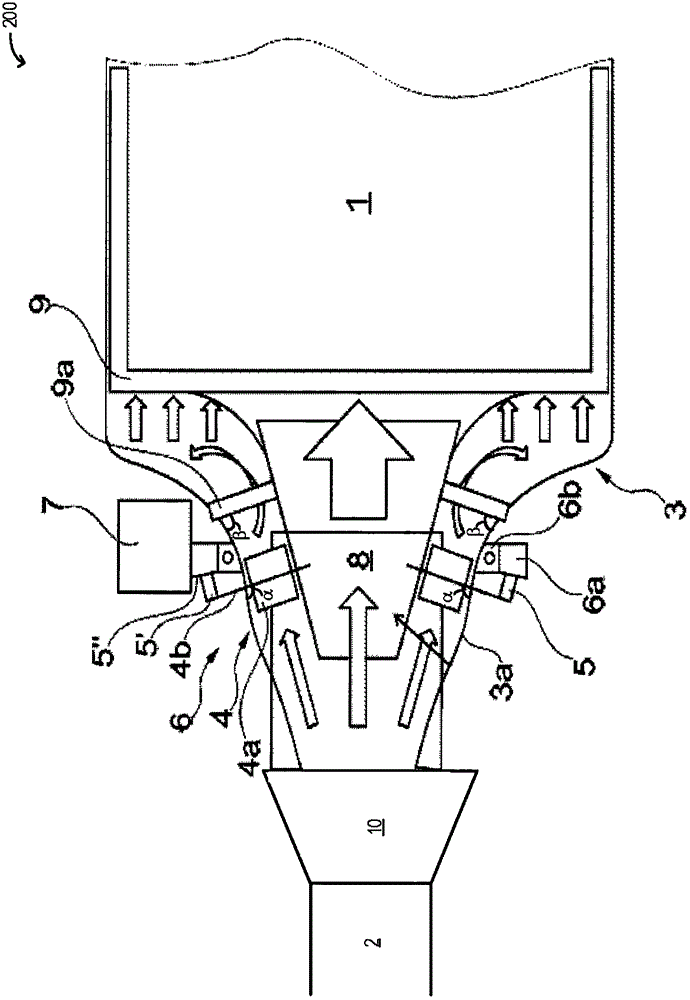

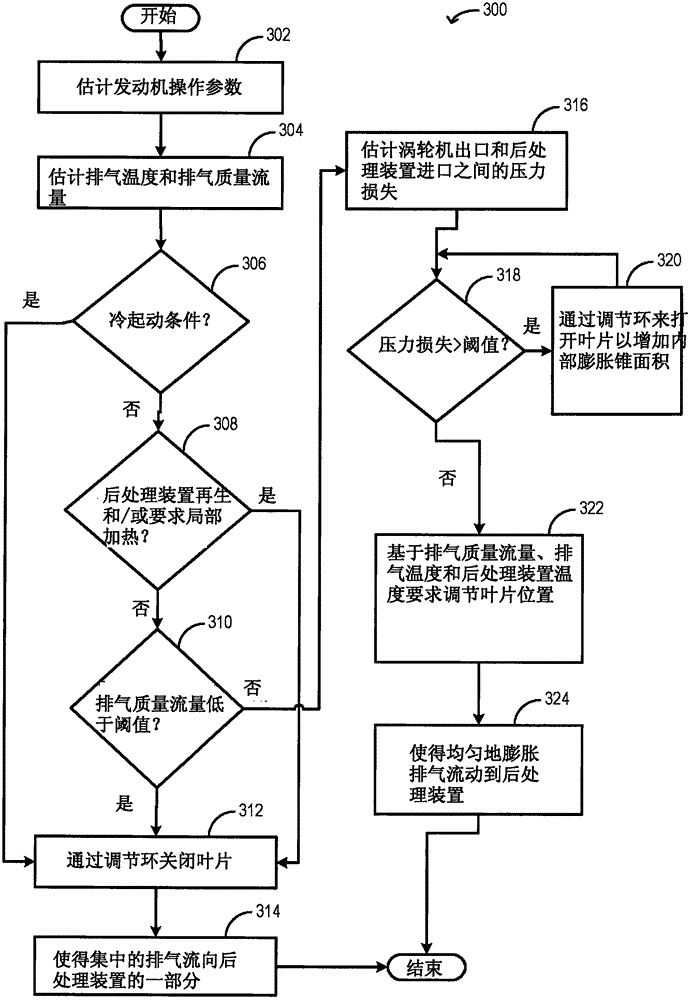

[0055] The following description relates to systems and methods for improving exhaust flow from an outlet of an exhaust turbine to an exhaust aftertreatment device via the turbine outlet cone. like figure 2 A longitudinal section of an exemplary engine system including a turbine outlet cone with adjustable swirl vanes is shown. The engine controller may be configured to execute control programs such as image 3 An example procedure in , to adjust the position (orientation) of the swirl vanes to optimize exhaust flow to the aftertreatment device based on changes in engine operating conditions.

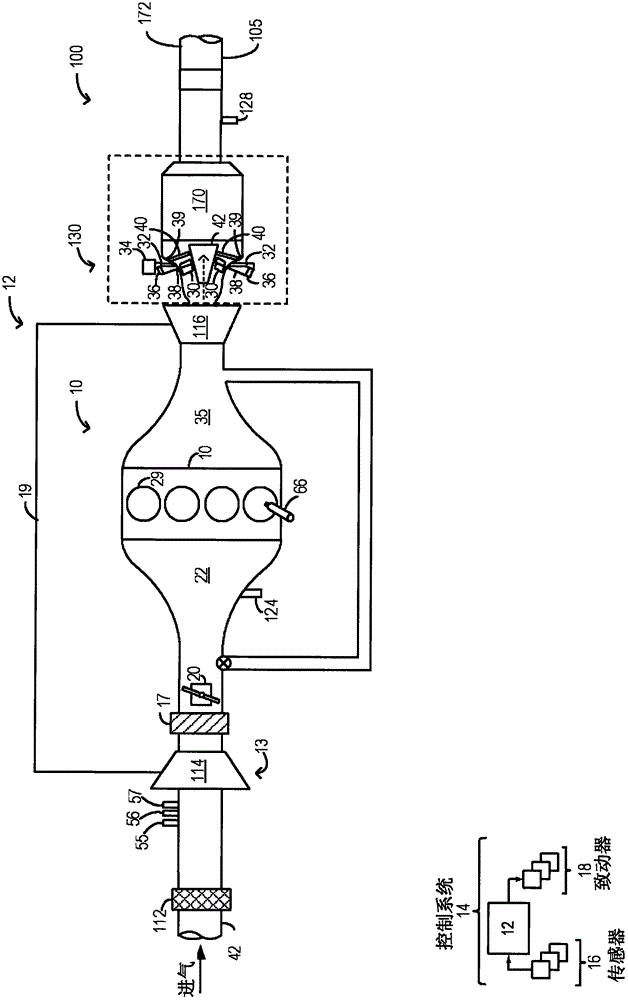

[0056] figure 1 Aspects of an example engine system 100 including an engine 10 are schematically shown. In the illustrated embodiment, the engine 10 is a booster engine connected to a turbocharger 13 including a compressor 114 driven by a turbine 116 . Specifically, fresh air is introduced into engine 10 along intake passage 42 via air cleaner 112 and flows to compressor 114 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com