Large-scale assembly integrated shear wall model structure and manufacture method

A technology of model structure and shear wall, which is applied in the direction of machine/structural component testing, measuring devices, building construction, etc., to achieve the effect of simple structure and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

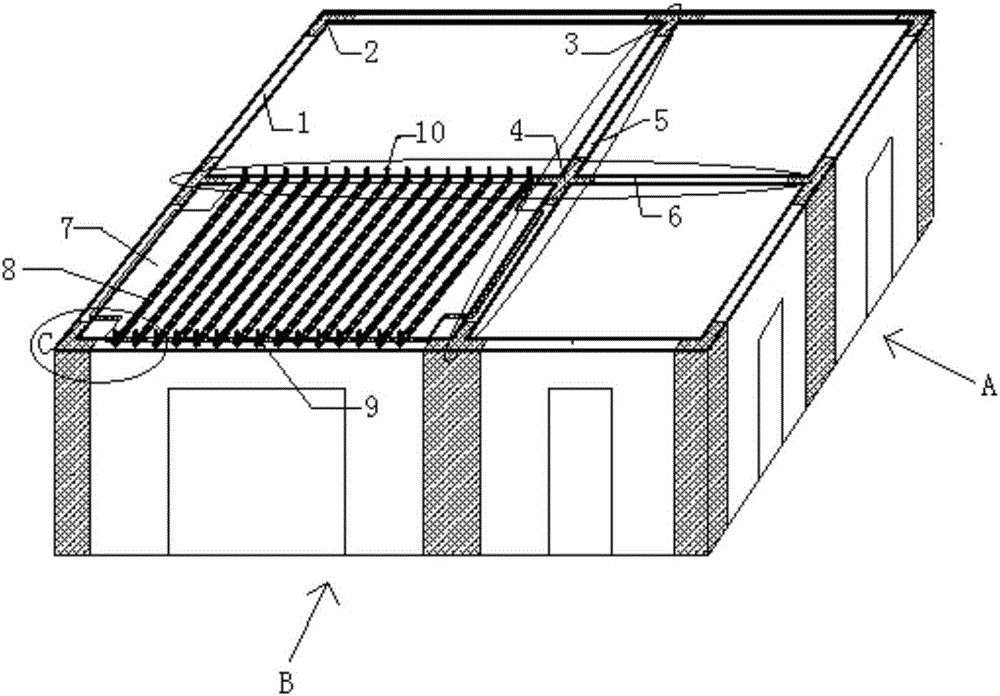

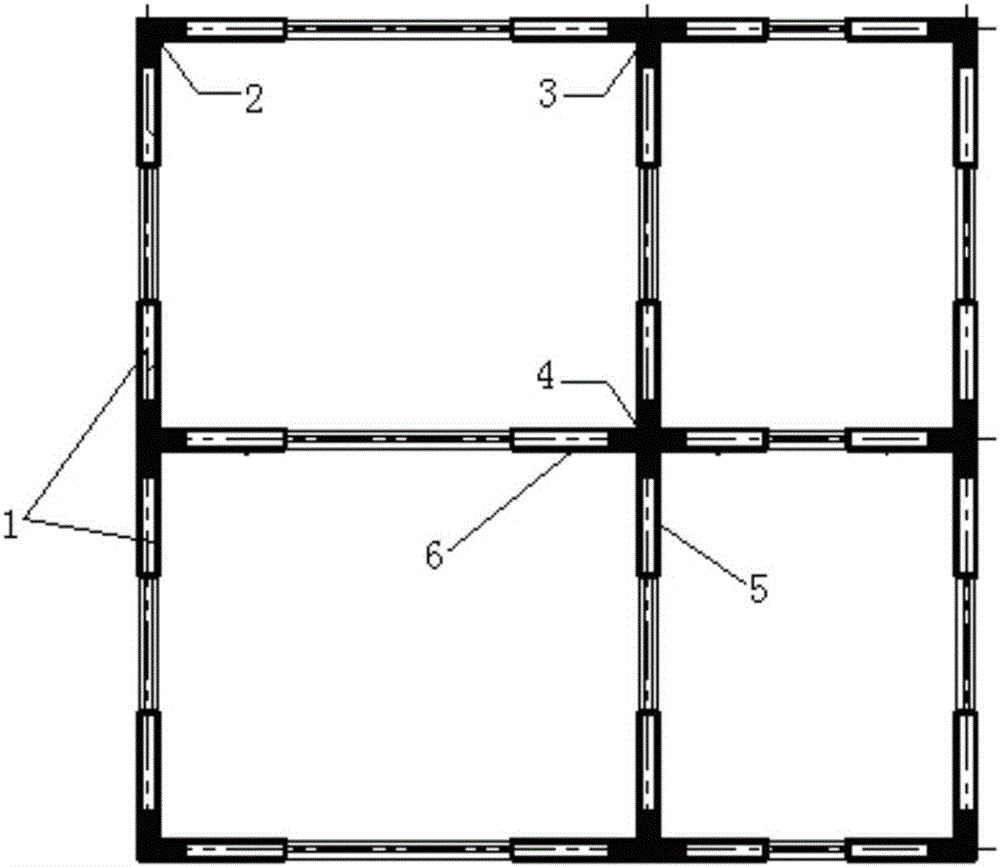

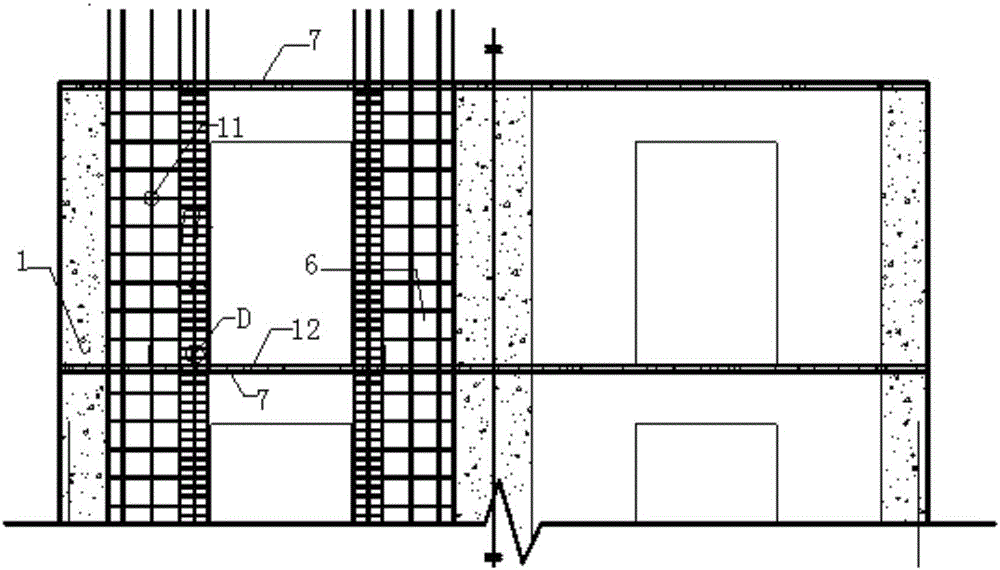

[0032] Comply with the above technical solutions, such as Figure 1 to Figure 7 As shown, a large-scale assembled integral shear wall model structure includes a prefabricated wall piece 1, a first inner transverse wall 5, a second inner transverse wall 6 and a connecting part, and the prefabricated wall piece 1 is provided with a door opening or Window hole; the connecting part in this scheme simulates three common connecting parts in the prototype structure, and the connecting part includes an L-shaped first connecting part 2, a T-shaped second connecting part 3 and a cross-shaped third connecting part 4, such as figure 1 shown.

[0033] The prefabricated wall piece 1 is provided with multiple sections, and the multi-section prefabricated wall piece 1 is jointly surrounded to form a rectangular structure. For example, this example in this embodiment is a square structure, and each side of the square structure is formed by more than one section of prefabricated wall piece 1 ;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap