A battery technology pole plate connection structure

A technology for connecting structures and batteries, applied in structural parts, battery pack parts, circuits, etc., can solve the problems of reducing the input-output rate of electrode plate production, de-powdering of electrode plates, cost waste, etc., and improve production input-output rate, prevent overall deformation, and reduce the effect of lead powder falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

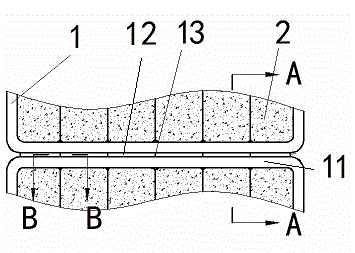

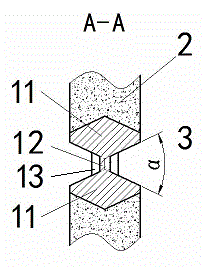

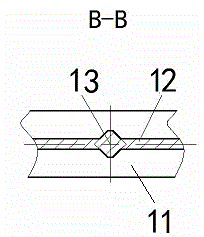

[0014] like Figure 1 to Figure 3 As shown, the present invention includes a grid 1 and an active material body 2 attached thereto, and a connecting block 12 is arranged between the frame ribs 11 of two adjacent grids 1, the connecting block 12 is in the middle position, and the adjacent grids The frame ribs 11 are arranged symmetrically, the thickness of the connecting block 12 is 0.2-0.3 times of the thickness of the frame ribs 11, the angle a between the two frame ribs 11 is 30°-80°, the height requirement of the connecting block 0.3-0.6cm, the connecting block 12 is provided with a number of equally spaced reinforcing ribs 13 . The thickness and width of the reinforcing ribs 13 are equal, which is 0.4-0.6 times of the thickness of the frame ribs 11 .

[0015] The cross-section of the frame rib 11 is rhombus (or ellipse).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com