Extrusion-resisting type housing of intelligent plastic housing controller

A controller and anti-extrusion technology, applied in the parts, electrical components, circuits of protection switches, etc., can solve problems such as deformation, achieve the effect of improving reliability, avoiding overall deformation, and solving poor reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the utility model is further described.

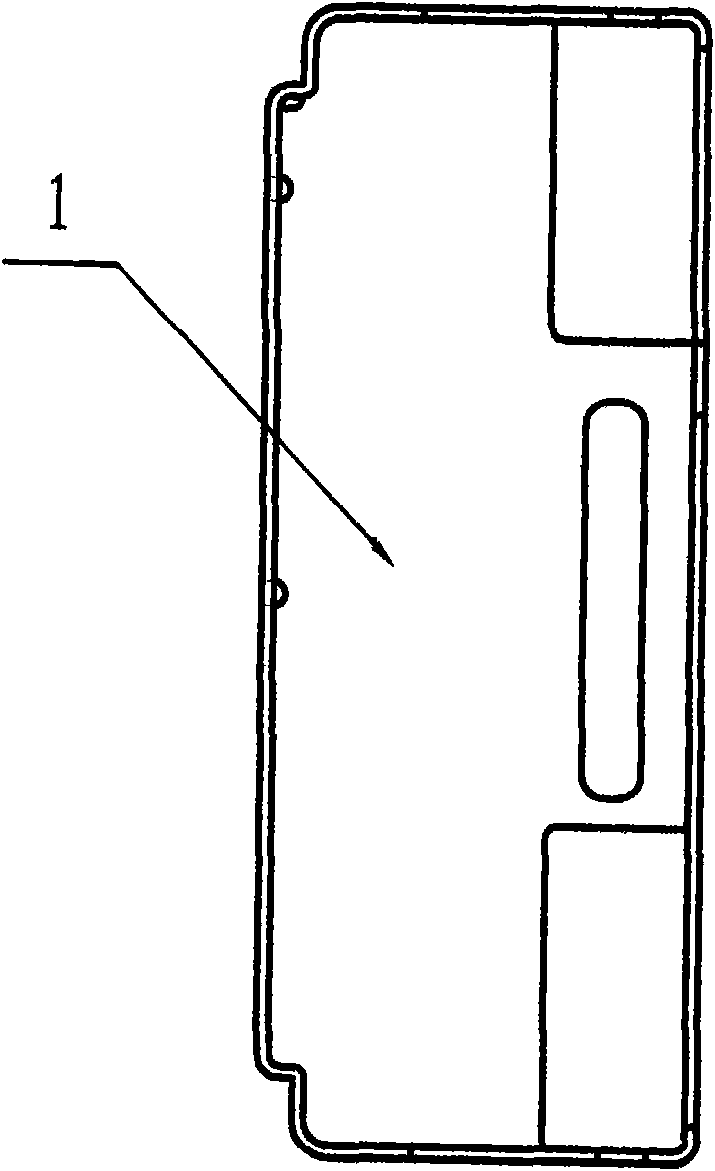

[0013] like figure 1 Shown is a schematic diagram of the structure of the existing controller shell. With the traditional structure of the controller shell, the shell 1 may have seams at the side corners after stamping and forming. When the shell 1 is squeezed by force, the seams will be Misalignment will occur to cause the overall deformation of the housing 1, thereby affecting the tripping and reset strokes of the tripping components installed on the housing 1, thereby seriously affecting the reliability of the circuit breaker.

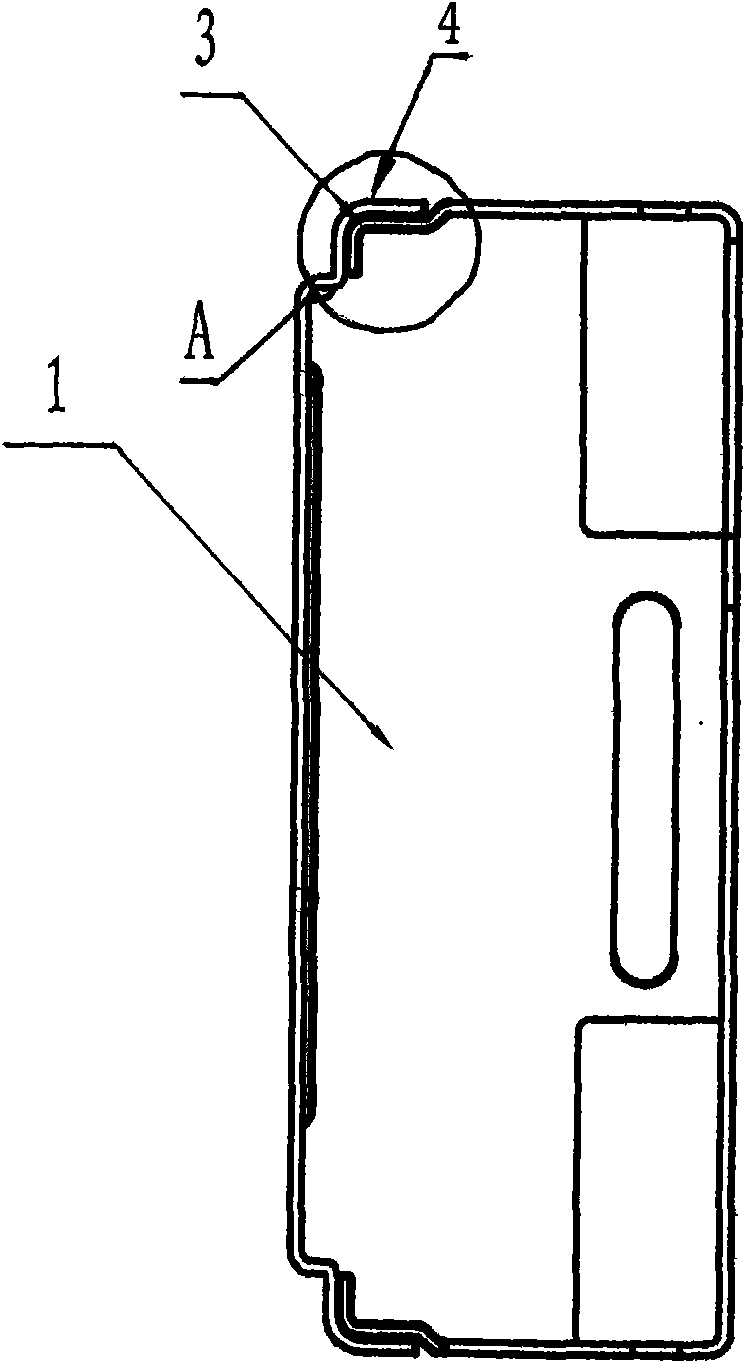

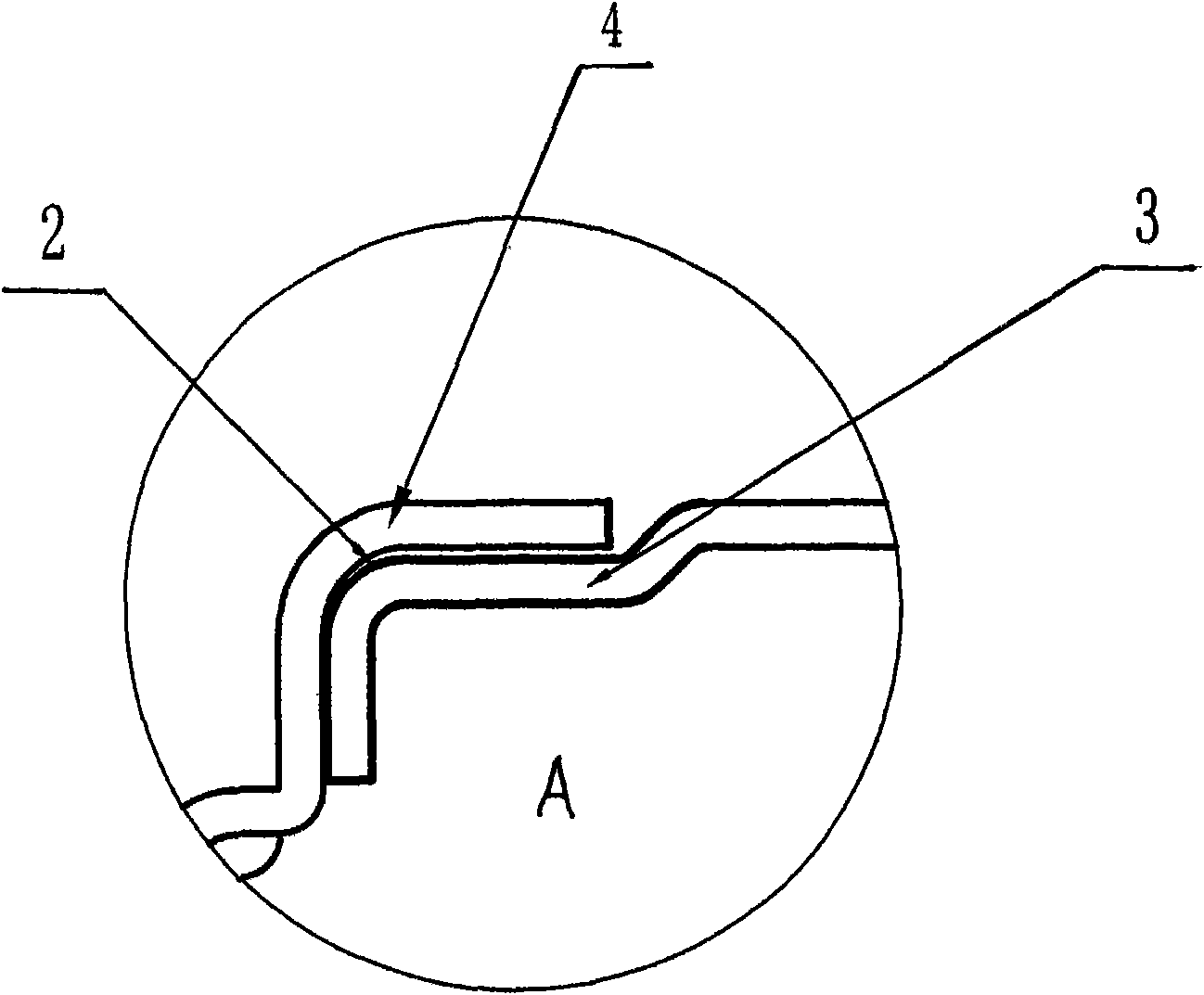

[0014] like figure 2 and image 3 As shown, the corners on the left and right sides of the front face of the controller shell shell 1 of the traditional structure adopt a two-layer fit design, the inner layer is an inner bend 3, the outer layer is a curved corner 4, and the inner layer of the inner layer There is a gap 2 between the bending 3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com