Pump for conveying a liquid, in particular an exhaust-gas cleaning additive

A technology for conveying liquid and conveying channels, applied in the field of exhaust gas purification devices, can solve the problems of difficulty in conveying and re-accepting, and achieve the effect of high sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

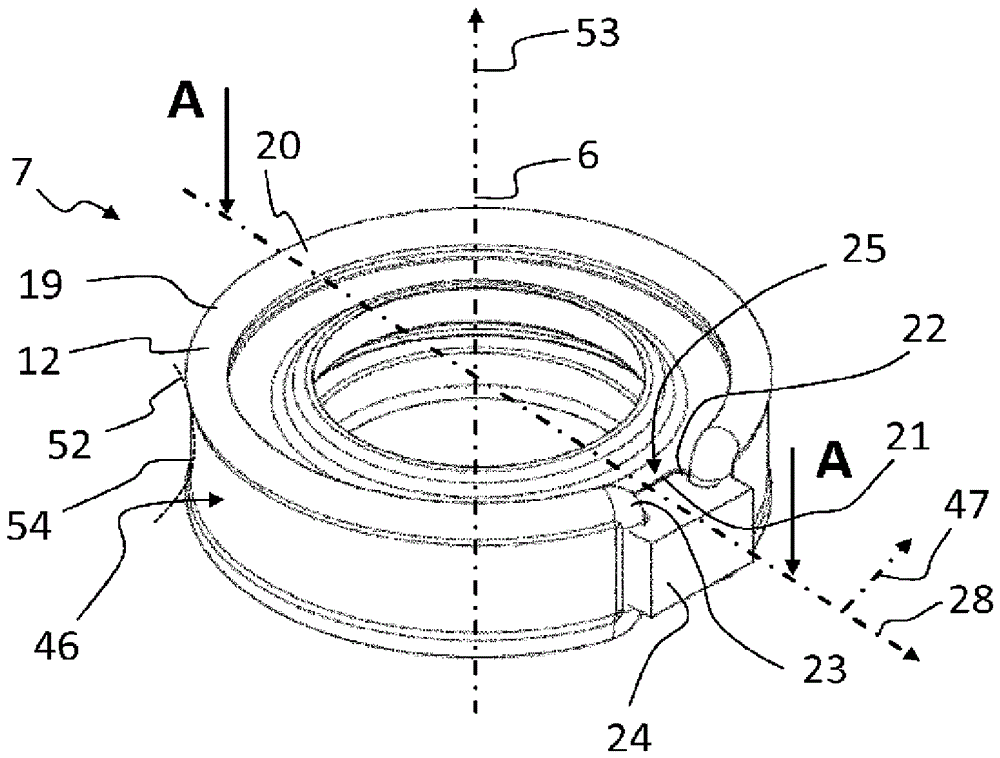

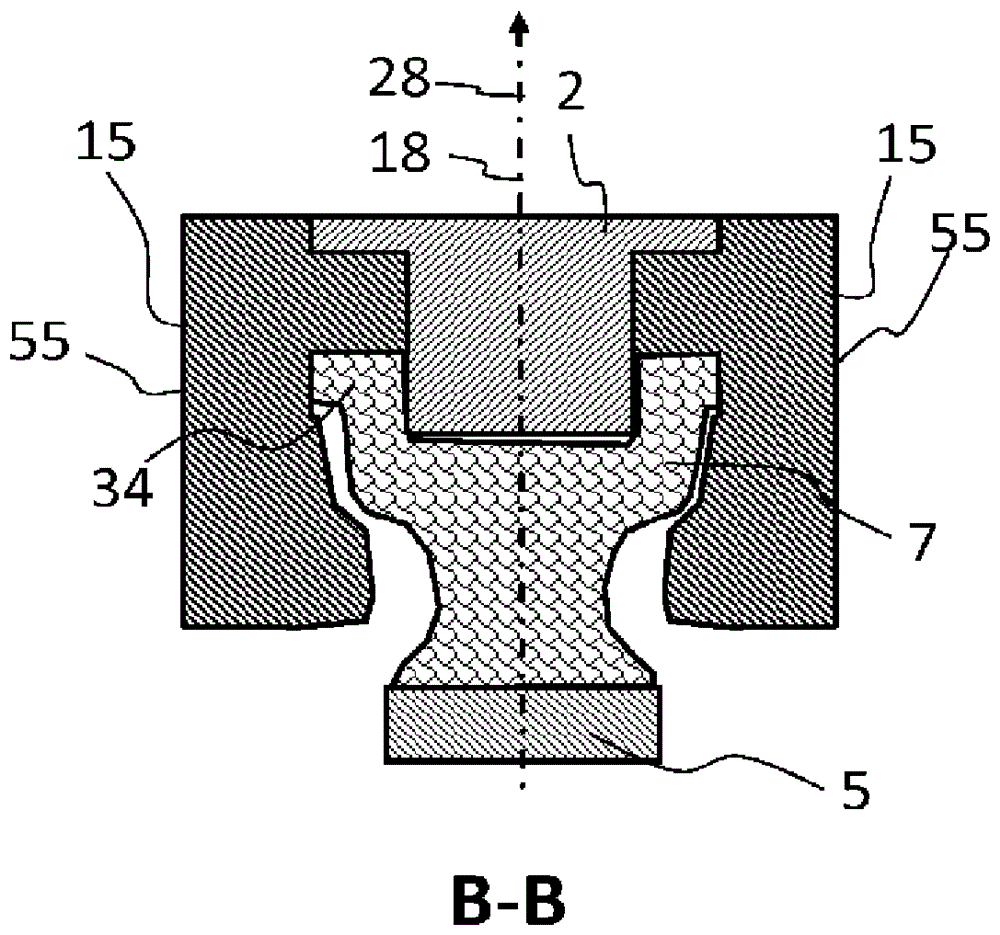

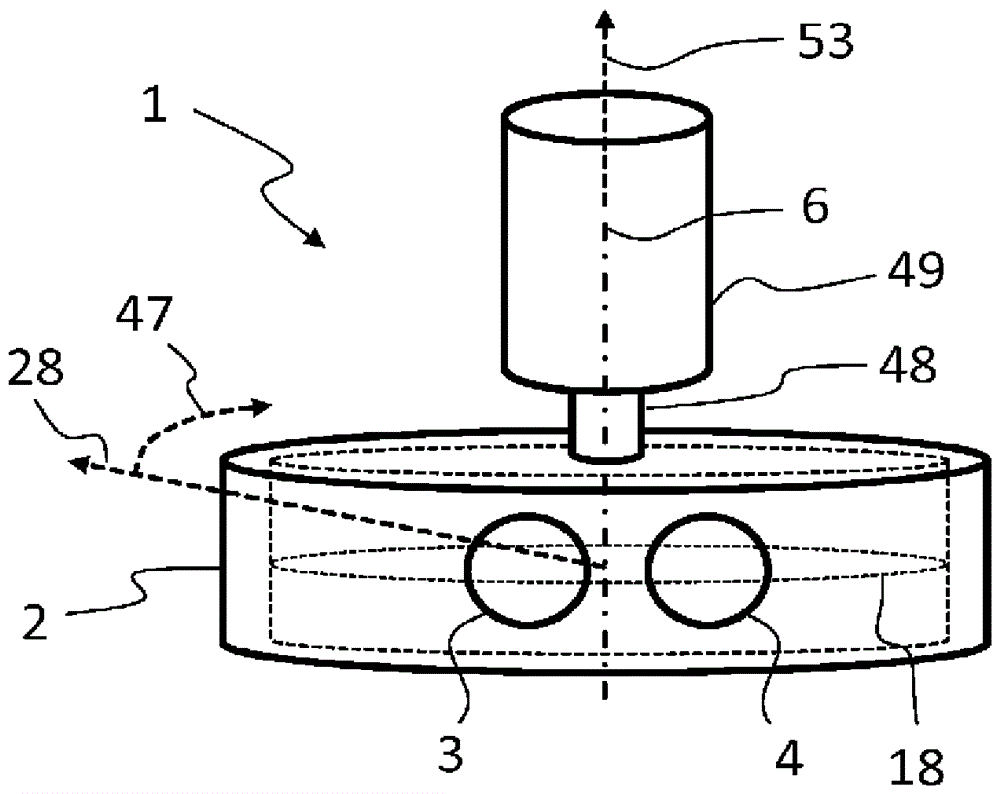

[0049] exist figure 1 A pump 1 can be seen, which has a pump housing 2 with an inlet 3 and an outlet 4 . An eccentric (not shown here) can be positioned in the pump housing 2 , which can be rotated to convey the liquid from the inlet 3 to the outlet 4 . For driving the eccentric along the geometric axis 53 of the pump 1 above the pump housing 2 is arranged an (electric) drive 49 which is connected to the eccentric via a drive shaft 48 . The geometrical axis 53 corresponds to the drive axis of the pump. In order to further explain the pump 1 , a cylindrical coordinate system should be specified here in addition to the geometric axis 53 , which has the geometric axis 53 ; the radial direction 28 perpendicular to the geometric axis 53 and the The geometrical axis 53 and the circumferential direction 47 of the radial direction 28 are arranged tangentially to the geometrical axis 53 . Furthermore, an intermediate plane 18 can be named, which centrally divides the pump housing 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com