High-strength and high-efficiency potato processing device

A processing device and potato technology, applied to excavators, digging harvesters, agricultural machinery and implements, etc., can solve problems such as rising cost, rising cost of final products, and restrictions on the development of the potato industry, and achieve cost reduction, high efficiency and cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

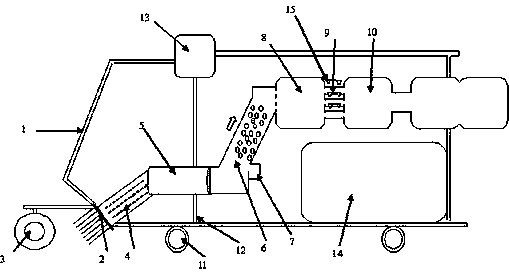

[0039] A high-strength and high-efficiency potato processing device includes a harvesting device and a cleaning device.

[0040] The harvesting device includes a sliding plough, a positioning wheel fixedly connected with the sliding plough, a position adjusting rod for controlling the position and inclination angle of the sliding plough, a regulating rod control part for controlling the position regulating rod, and a desilting drive connected with the back of the sliding plough. Parts, a seedling removal part connected with the tail end of the processing transmission part, a tilting transmission part connected with the outlet of the seedling removal part, a seedling collecting part arranged on the side of the inclined transmission part, a potato screening device connected with the end of the tilting transmission part, and a frame , travel wheels and controls.

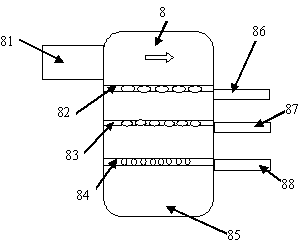

[0041] The cleaning device includes a plurality of classified potato conveying parts connected with the outlet of the...

Embodiment 2

[0063] A high-strength and high-efficiency potato processing device includes a harvesting device and a cleaning device.

[0064] The harvesting device includes a sliding plough, a positioning wheel fixedly connected with the sliding plough, a position adjusting rod for controlling the position and inclination angle of the sliding plough, a regulating rod control part for controlling the position regulating rod, and a desilting drive connected with the back of the sliding plough. Parts, a seedling removal part connected with the tail end of the processing transmission part, a tilting transmission part connected with the outlet of the seedling removal part, a seedling collecting part arranged on the side of the inclined transmission part, a potato screening device connected with the end of the tilting transmission part, and a frame , travel wheels and controls.

[0065] The cleaning device includes a plurality of classified potato conveying parts connected with the outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com