Steel-bar-free high-heeled shoe insole and manufacturing method thereof

A production method and technology for high-heeled shoes, which are applied to shoe soles, footwear, heel pads, etc., can solve the problems of poor comfort, complicated preparation process, poor wearing comfort of midsole, etc., so as to improve wearing comfort, reduce production costs, easy separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

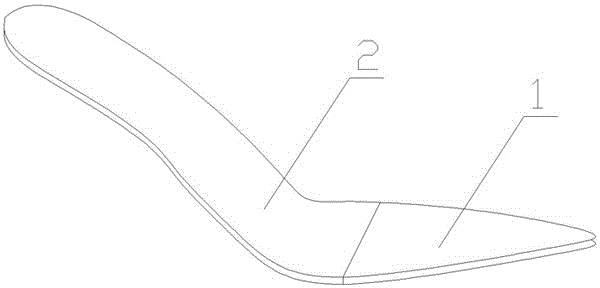

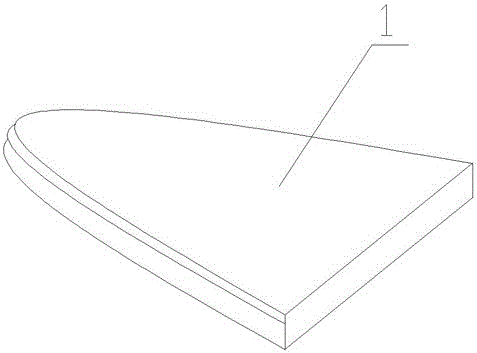

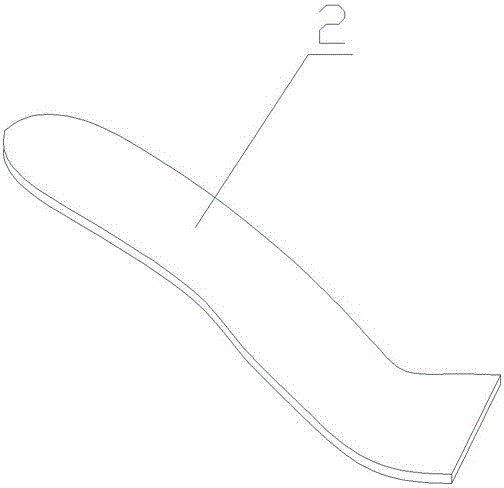

[0032] Such as Figure 1-Figure 3 As shown, a high-heeled midsole free of steel bars includes a front midsole 1 and a rear midsole 2, both of which are arc-shaped planes; the arc-shaped plane of the rear midsole 2 gradually extends upwards , the extended part is the middle part and the heel of the rear midsole 2.

[0033] In this embodiment, the entire midsole structure is divided into a front midsole 1 and a rear midsole 2. It is mainly considered that the midsole structure of high-heeled shoes in the prior art is an integrated structure, and the materials used are the same. During walking, the forefoot is close to the steel bar structure, and the comfort is poor.

Embodiment 2

[0035] On the basis of Example 1, this embodiment defines that the front midsole 1 is made of EVA material,

[0036] The front midsole 1 made of EVA material in this embodiment has good flexibility and strong shock absorption performance, and is quite comfortable when women wear it. Especially in the process of walking, the forefoot is firmly attached to the area where the front midsole 1 is located, and because the thickness of the front sole of the shoe itself is relatively low, the front midsole 1 made of EVA material is easy to use.

Embodiment 3

[0038] In this embodiment, on the basis of the foregoing embodiments, the rear midsole 2 is further limited to be made of PU material. The PU material is a known material, and the rear midsole 2 made by it has a certain hardness and is not easy to be corroded or damaged by other materials. External force and other damage, has a strong mechanical properties.

[0039] Therefore adopt rear midsole 2 that PU material is made, and it is positioned at the middle part or heel of footwear, can carry body weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com