Gravity type automatic ball serving machine

A ball machine, automatic technology, applied in the direction of sports accessories, etc., can solve the problems of the ball machine not working, affecting the user's hitting level, and inconvenient to clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

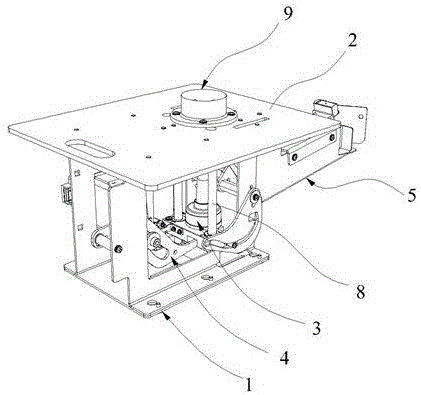

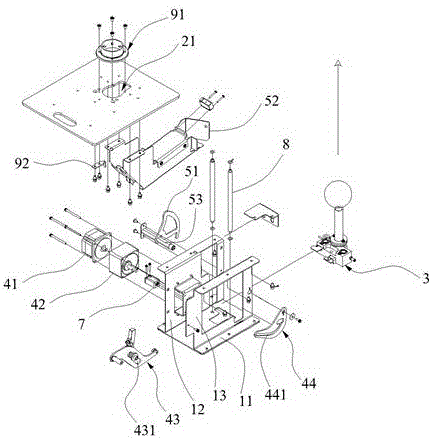

[0030] refer to Figure 1 to Figure 4 , the present invention provides a gravity type automatic ball serving machine, comprising:

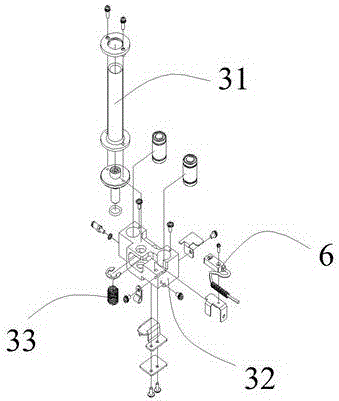

[0031] Bottom frame 1 and upper cover plate 2, a liftable TEE seat assembly 3, a power mechanism 4, a ball supply assembly 5, a gravity sensor 6, and a TEE seat lift sensor 7.

[0032] Wherein, the bottom frame 1 and the upper cover plate 2 constitute the overall frame of the ball machine, and the upper cover plate 2 is provided with an opening groove 21 for balls to pass through. The vertical side walls 12, 13, and the inner sides 12, 13 of the two vertical side walls are also provided with two vertical slide rails 8.

[0033] Wherein, TEE seat assembly 3 comprises ball TEE 31, ball TEE base 32 and the pressure spring 33 between them; On the ball TEE base 32; when the ball TEE 31 loads a sphere, the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com