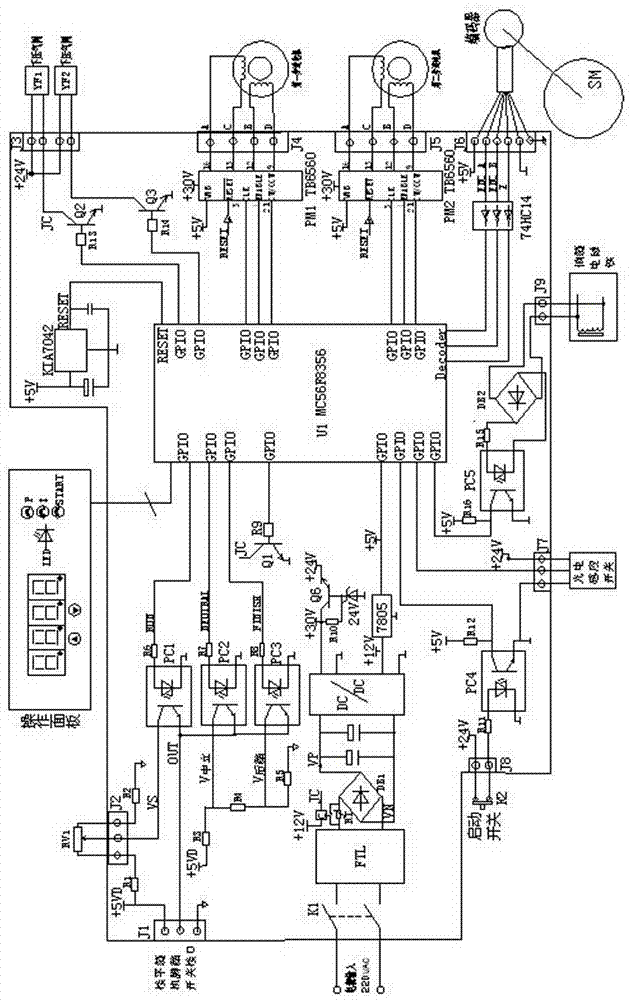

Full-automatic electronic cloth dragging wheel control system for sewing die plate

A control system and fully automatic technology, which is applied in sewing equipment, textiles and paper making, etc., can solve the problems of inability to transfer templates, etc., and achieve the effect of stable sewing process, wide application range, and convenient and flexible setting parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

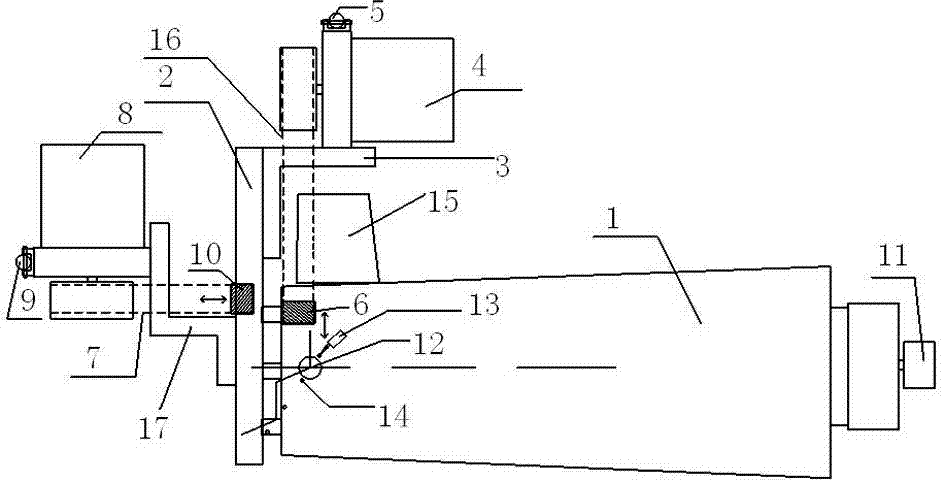

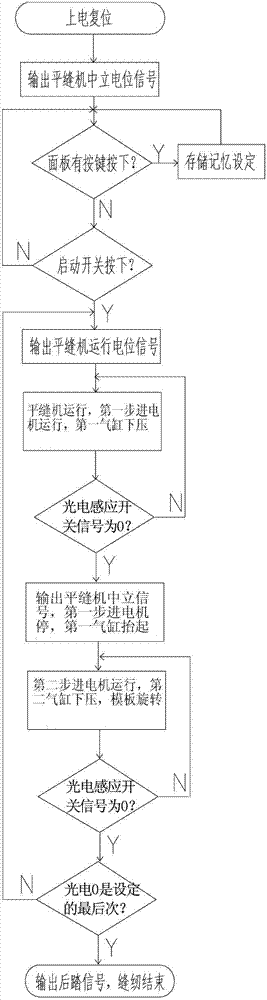

[0011] refer to figure 2 , a fully automatic electronic mop control system for template sewing, the sewing machine panel mounting plate 2 is fixed on the left side of the sewing machine head 1, and the second stepper is fixed on the left side of the sewing machine panel mounting plate 2 through the second mounting plate 17 The motor 8 and the second cylinder 9, the output shaft of the second stepping motor 8 are interlocked with the second tug wheel 10 fixed on the sewing machine panel through the toothed conveyor belt b16, and control the movement of the mop in the X direction. The right end of the sewing machine head 1 is provided with an encoder 11, the right side of the needle bar 12 is provided with a photoelectric sensor switch 13, and reflective paper 14 is provided at each corner of the template below the needle bar, and the sewing machine panel mounting plate 2 is located at the rear side of the sewing machine head 1. The first mounting plate 3 is fixed with the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com