Device for brushing glue on ball bladder

A technology of brushing glue and bladder, which is applied in the direction of devices and coatings for coating liquid on the surface, can solve the problems of inconvenience and low efficiency, and achieves the advantages of strong practicability, preventing glue from sticking to hands, and improving the efficiency of glue brushing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

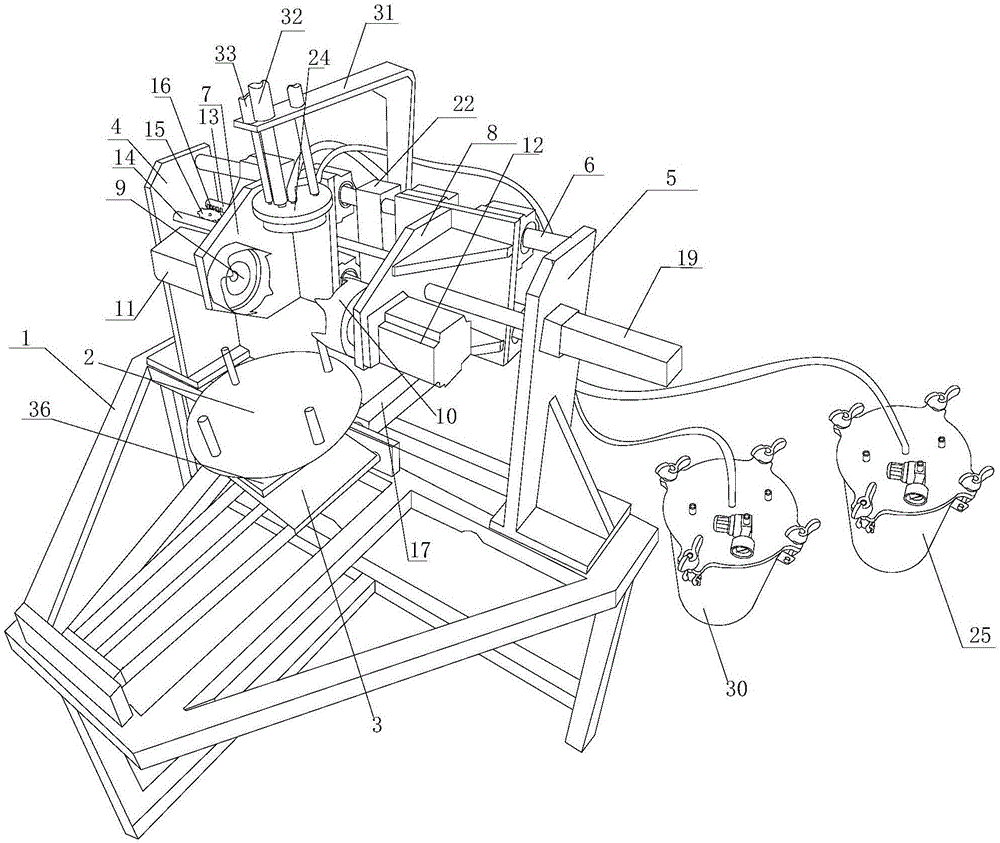

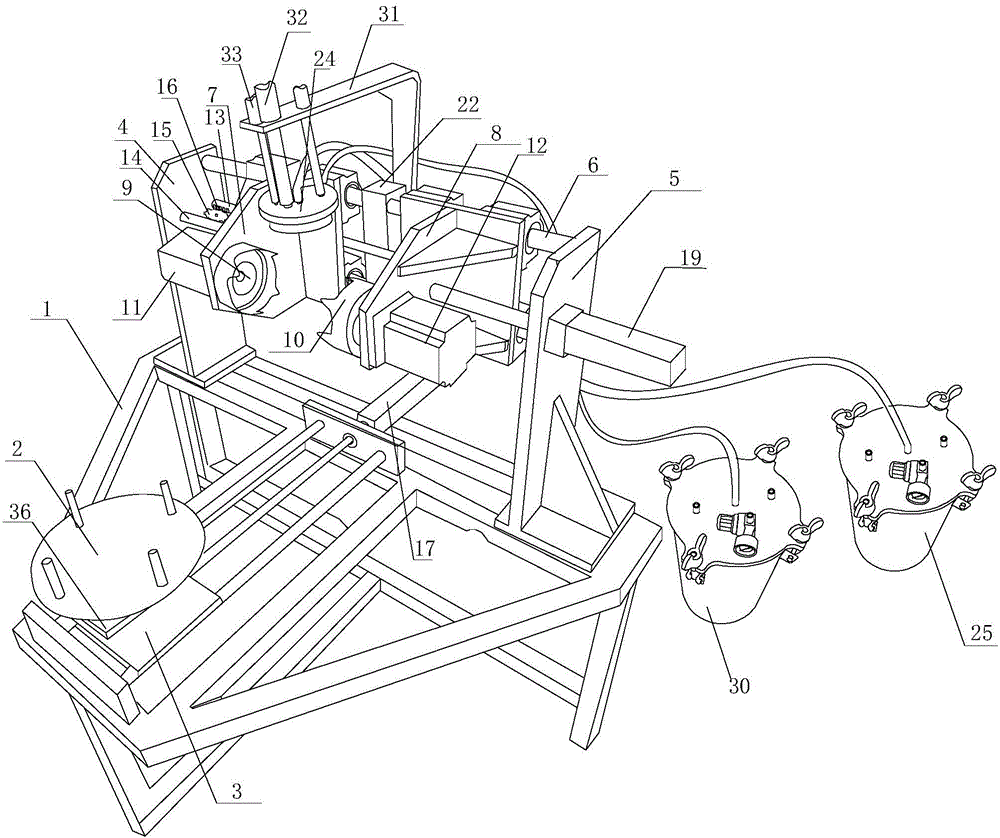

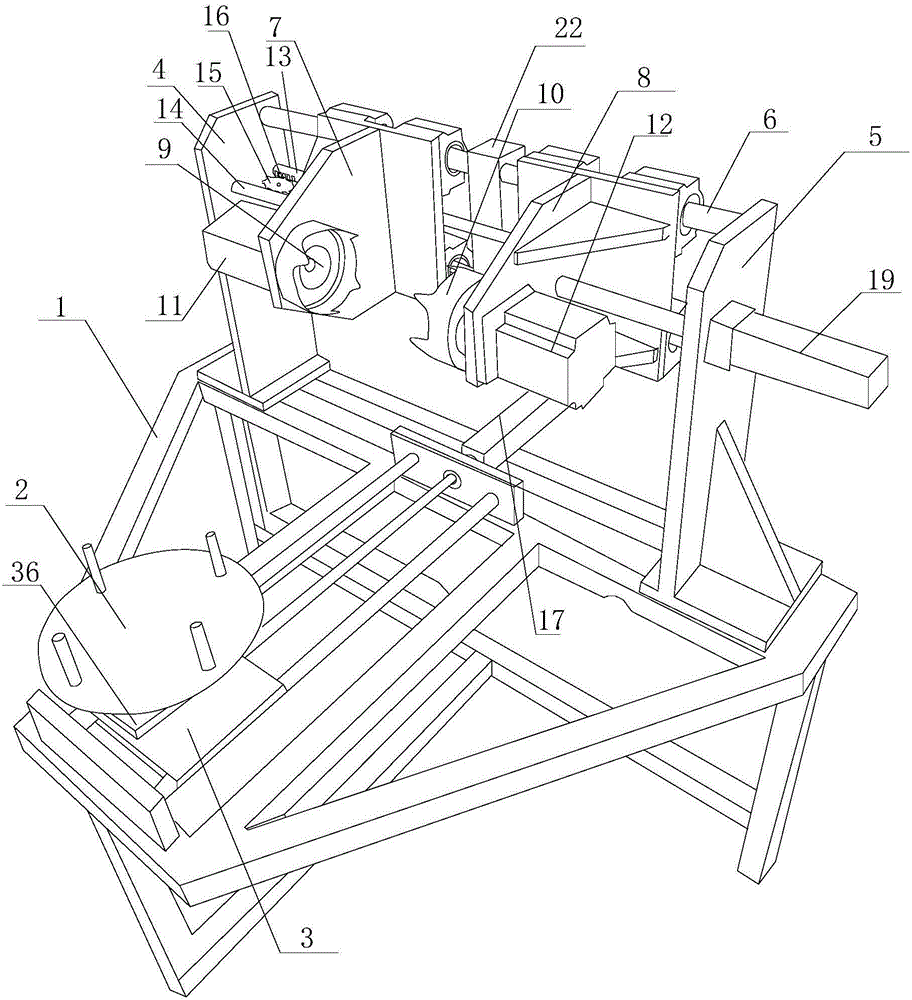

[0020] Such as Figure 1-7 Shown: a bladder brushing device, which includes a transmission system and a glue brushing machine; the transmission system includes a frame 1, which is arranged on the frame 1 and is used to clamp the bladder and drive the bladder to rotate The jig and the supporting assembly located directly below the jig, the supporting assembly includes a tray 2 and a rotating lifting device arranged under the tray 2 and connected to the tray 2, the rotating lifting device makes the tray 2 move up and down and makes the tray 2 Rotate with its central axis; the glue brushing machine includes a swing motor 23 and a glue brush 24 connected with the swing motor 23, and the glue brush 24 is located above the clamp;

[0021] The relationship between the transmission system and the glue brushing machine is as follows: the ball liner is placed on the tray 2, the rotating lifting device pushes the tray 2 upwards, and the ball liner is sent to the fixture, and the fixture ...

Embodiment 2

[0059] Embodiment 2: The structure of Embodiment 2 of the present invention is substantially the same as that of Embodiment 1. The main difference is the difference in the number, size and position of the rubber brush shunt partitions 29, such as Figure 8 Shown: in embodiment two: described diversion divider 29 is arranged between the top surface and the bottom surface of brush plate 26, and divider divider 29 divides brush disc 26 into upper and lower two chambers, and the upper end of bristle 27 and diverter divider The lower surface of the plate 29 is in close contact.

Embodiment 3

[0060] Embodiment 3: The structure of Embodiment 3 of the present invention is substantially the same as that of Embodiment 2. The main difference is the difference in the position of the flow divider 29 and the bottom surface of the brush plate 26 is detachable, such as Figure 10 As shown: in the third embodiment, the flow divider 29 is arranged between the top surface and the bottom surface of the brush plate 26, and the lower surface of the flow divider 29 is in close contact with the upper surface of the bottom surface of the brush plate 26, and the flow divider 29 The bottom surface of the brush plate 26 is provided with a glue outlet corresponding to the socket and the glue spray hole 28, and the bottom surface of the brush plate 26 is a detachable structure. In the third embodiment, the shunt baffle 29 plays a role of shunting, and at the same time when the bottom surface of the brush plate 26 is removed together with the bristles, the bristles can be soaked and cleaned. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com