Storage device for fibre material with cleaning unit

A storage device, fiber material technology, applied in storage devices, cleaning methods and utensils, fiber processing and other directions, can solve the problem of expensive air cleaning, and achieve the effects of saving suction equipment, low maintenance cost, and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

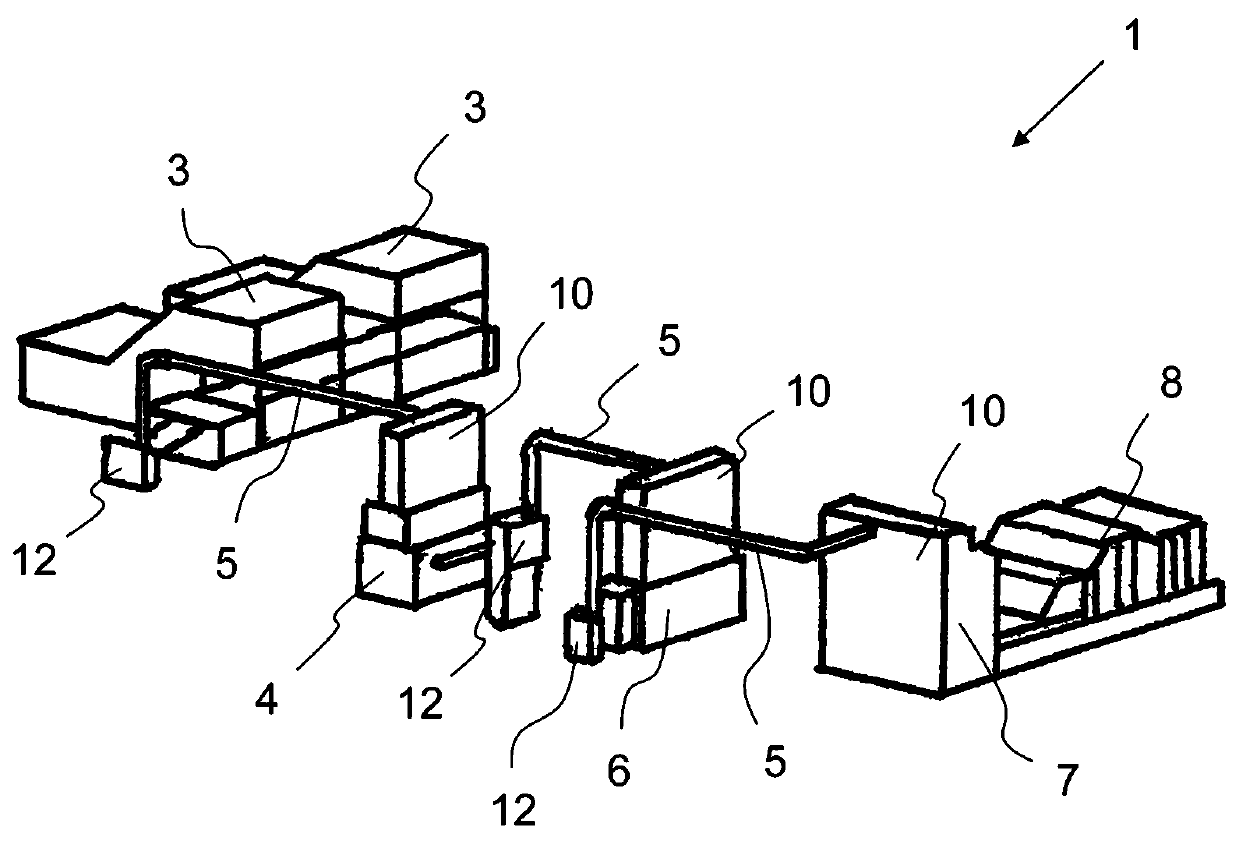

[0043] figure 1 An exemplary embodiment of a textile plant 1 is shown, which is currently configured for the production of nonwoven fabrics. The fibrous material 2 provided as bales is opened by a bale opener 3 and dropped onto a conveyor belt. The opened fiber material 2 is then fed via a tubular line 5 to a mixing opener 4 , by means of which the fiber material is subjected to a first loosening and further mixing. From the mixing opener 4 the fibrous material 2 passes through a further tubular line 5 into a final opener 6 in which the fibrous material is subjected to final opening. The fibrous material passes through the third tubular line 5 finally to the filling shaft feeder 7 from which the carding machine 8 is fed. The conveying of the fibrous material 2 via the tubular line 5 is effected by means of at least one pneumatic conveying device 12 which generates a conveying air flow 29 by means of a fan.

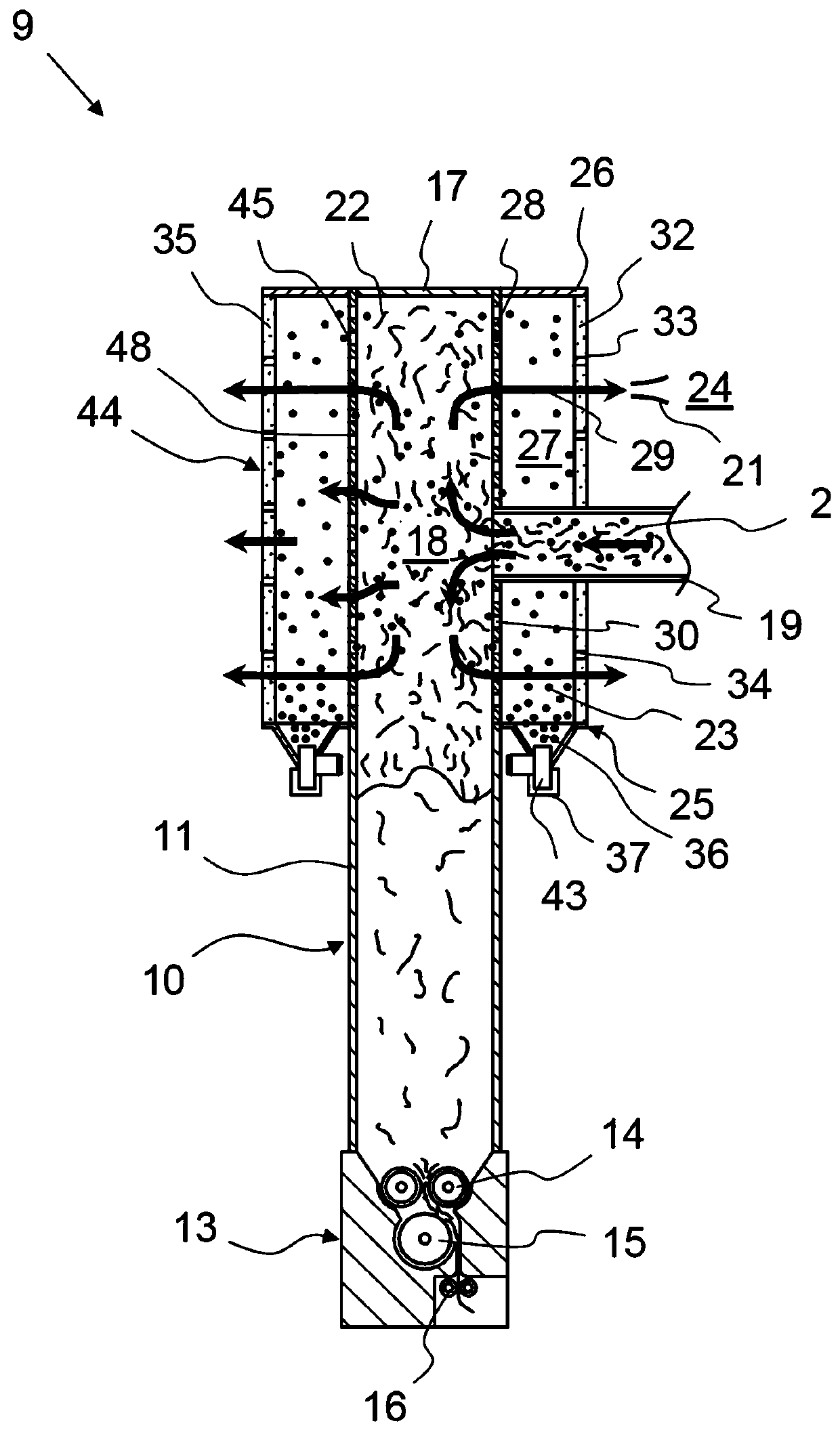

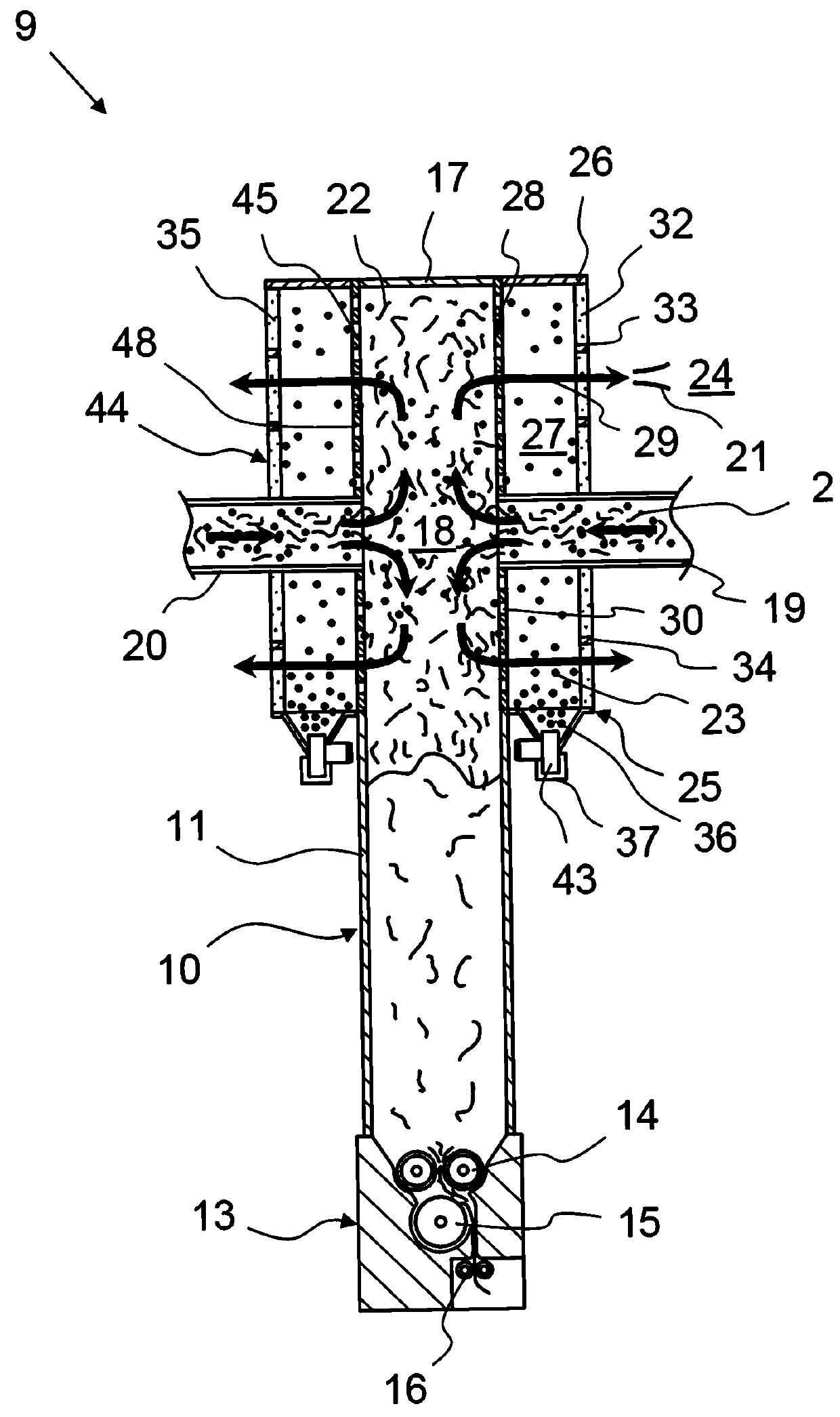

[0044] The mixing opener 4 , the finishing opener 6 and the stuffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com