Method for predicting and controlling solidification of casting flow in secondary cooling segment in continuous casting process

A control method, the technology of the secondary cooling section, applied in the field of advanced industrial manufacturing control, can solve the problems of increasing the cost of use, unsolved casting strand solidification process, and lack of guarantee for instrument reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

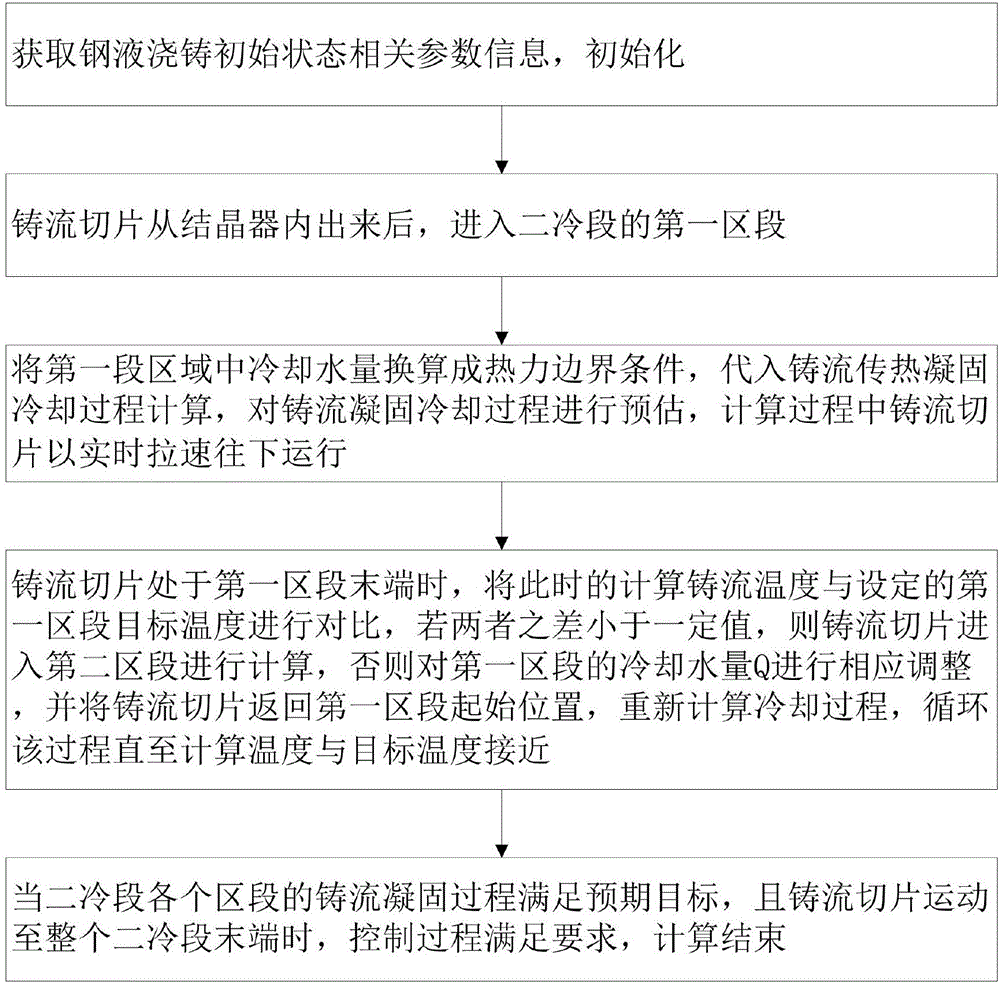

[0043] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0044] see figure 1 , the present invention provides a method for predicting and controlling strand solidification in the secondary cooling section of the continuous casting process, comprising the following steps:

[0045] S1. Obtain relevant parameter information of the initial state of molten steel casting, and initialize;

[0046] S2. After the strand slice comes out of the crystallizer, it enters the first section of the secondary cooling section;

[0047] S3. Convert the amount of cooling water in the first section into thermal boundary conditions, substitute it into the calculation of the heat transfer, solidification and cooling process of the casting strand, and estimate the solidification and cooling process of the strand. During the calculation process, the strand slices run downward at real-time pulling speed;

[0048] S4. When the strand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com