Wire feeding mechanism

A technology of wire feeding mechanism and wire feeding gear, which is applied to arc welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as inability to ensure success rate, low work efficiency, troublesome operation, etc., and achieve enhanced work continuity and improved Improvement of welding quality and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

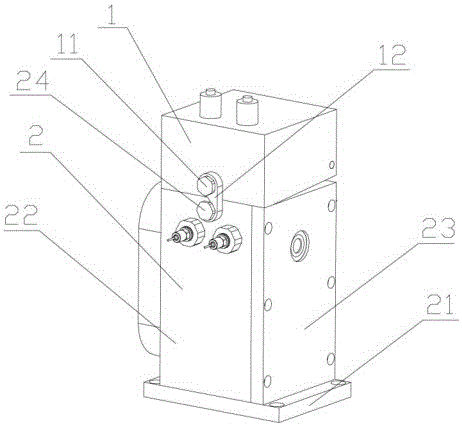

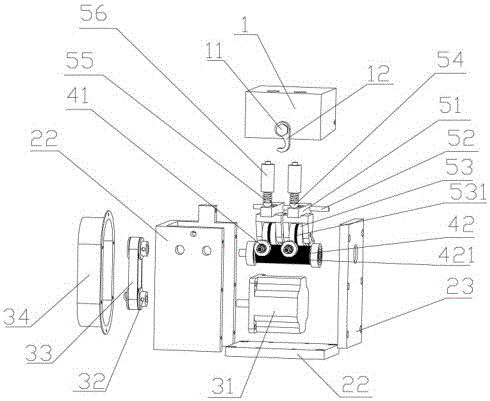

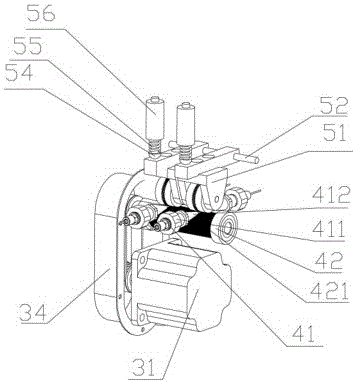

[0019] 1 to 3 schematically show a wire feeding mechanism according to the present invention.

[0020] According to one aspect of the present invention, a wire feeding mechanism is provided, including an upper cover 1, a body 2, a stepping drive mechanism, a wire feeding mechanism and a positioning mechanism; wherein the body 2 includes an interconnected base 21, a "concave" shape The frame 22 and the fixing plate 23 adopt a split structure, which is more convenient and quick in assembly, disassembly and maintenance.

[0021] Stepping drive mechanism comprises stepping motor 31, delivery wheel 32, transmission belt 33 and protection frame 34, and stepping motor 31 is installed in the lower end of frame 22, and the rotor of stepping motor 31 passes through frame 22 and connects with delivery wheel 32 connection, the protective frame 34 is fixed on one side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com