Wire feeding device

A wire feeding device and wire feeding wheel technology, applied in tin feeding devices, metal processing equipment, manufacturing tools, etc., can solve the problem of inability to observe wire threading in real time, inability to ensure success rate, easy to bend and block the wire outlet, etc. problems, to achieve the effect of improving welding quality, uniform pressing force and good orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

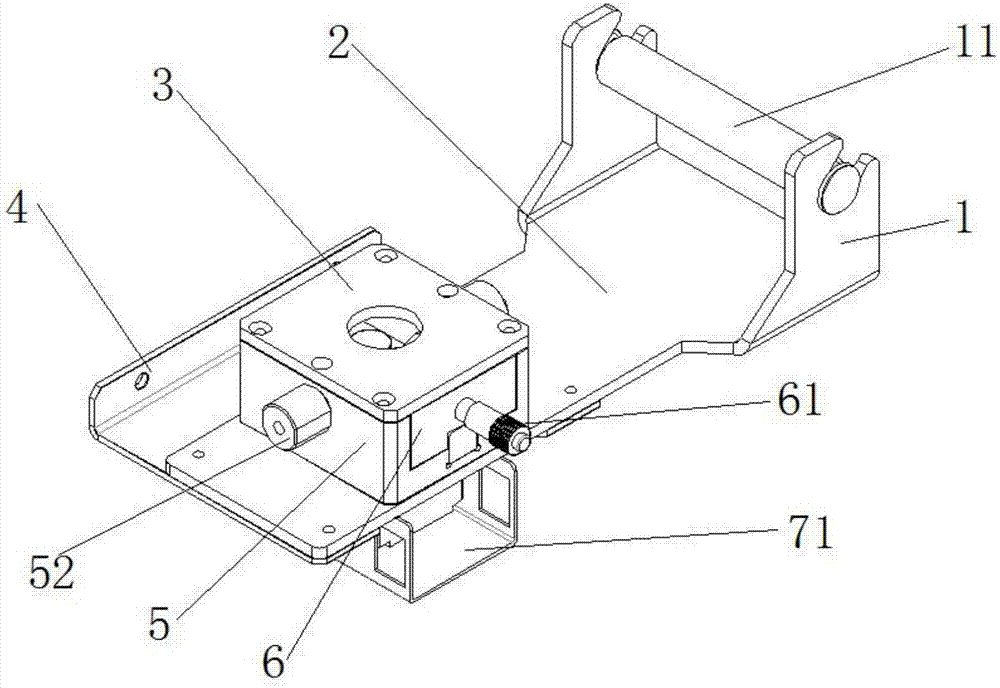

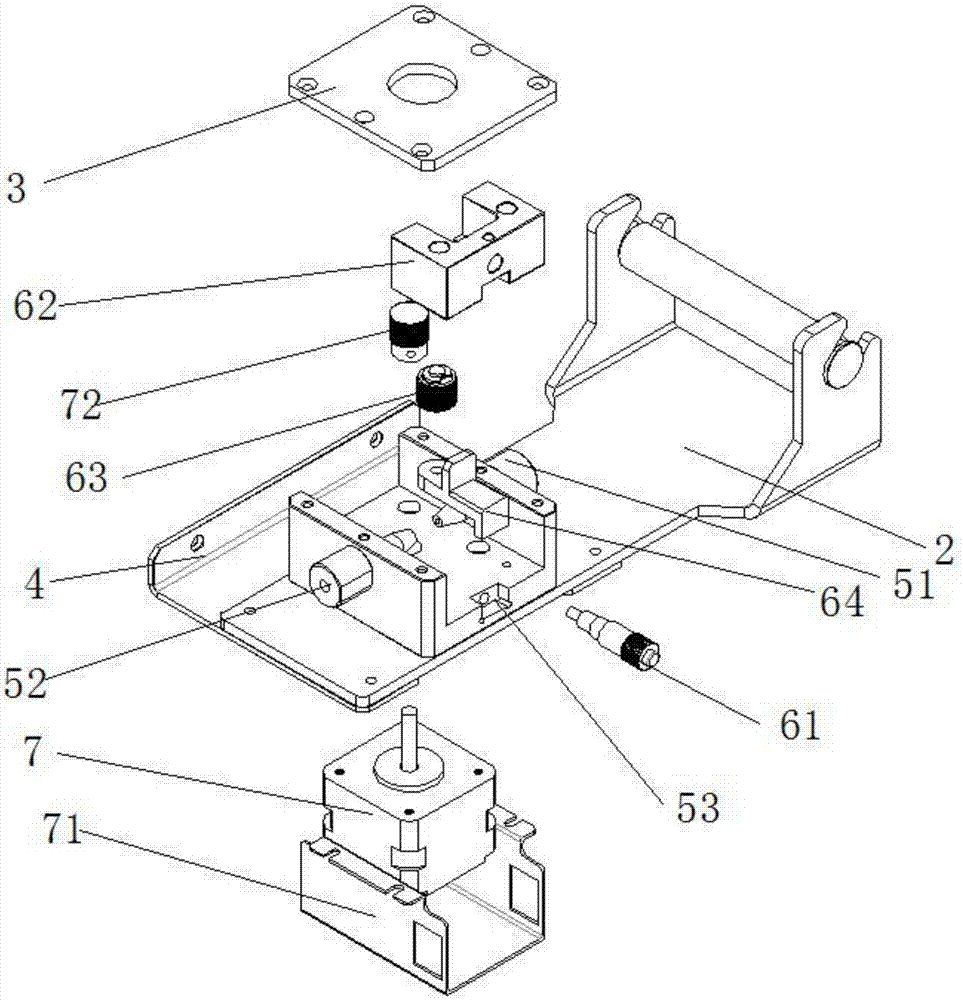

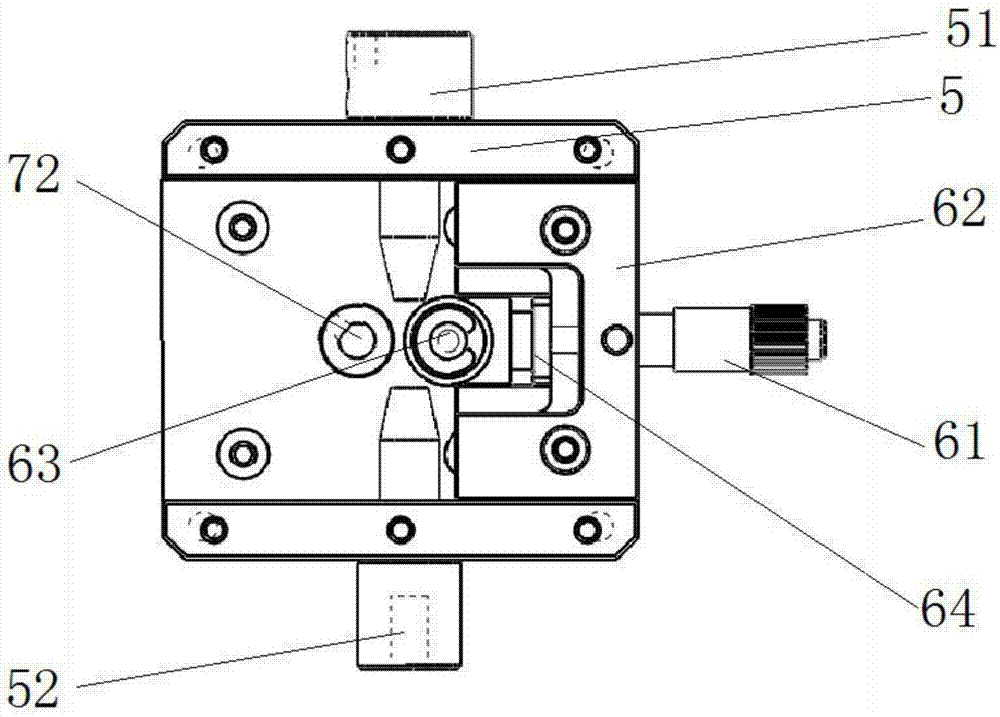

[0021] refer to figure 1 , figure 2 , image 3 , a kind of wire feeding device, comprises frame 2, and described frame 2 is provided with a frame groove 5, and described frame groove 5 is provided with cover plate 3, and described frame groove 5 is provided with a wire feed wheel 72. The wire feed wheel 72 is arranged on the output shaft of the motor 7, and the motor 7 adopts any one of a DC speed-regulating motor or a stepping motor. The preferred solution of this embodiment is that the motor 7 is a stepper Into the motor, the side of the frame slot 5 is provided with a pressing mechanism 6, which can accurately control the feeding speed of the welding wire and the length of the welding wire to prevent waste caused by excessive delivery of welding wire;

[0022] Described pressing mechanism 6 comprises pinch wheel frame 64, pinch wheel 63, adjustment di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com