One-piece clamp for automotive welding

A clamp and integrated technology, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of limited clamping output torque of eccentric clamping cylinder, poor application effect, and inability to realize self-locking, etc., to achieve Fast adjustment, lower application cost, and convenient on-site adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

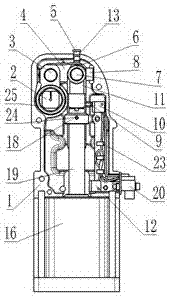

[0020] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

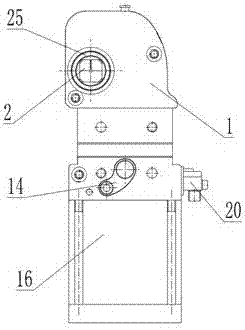

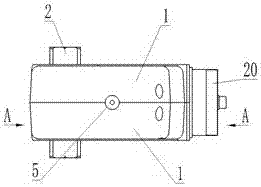

[0021] Such as Figure 1-Figure 5 As shown, an integrated clamp for automobile welding, the clamp includes a housing 1, a cylinder 16, a connecting rod mechanism, a bevel gear matching mechanism and a proximity switch mechanism; the connecting rod mechanism and the bevel gear Cooperating mechanisms are respectively arranged in the upper and lower parts of the housing; the lower part of the housing 1 is provided with a cylinder 16, the cylinder 16 is installed on the housing 1, and the cylinder piston rod 19 is connected with the active rod 11; the lower part of the housing side is provided with a mounting hole, A dustproof cover 14 is installed on it; one side of the adjacent active rod 11 in the housing 1 is provided with a proximity switch bracket 23 in the proximity s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com