Base of full-automatic swing arm type cutting machine

A swing arm type, fully automatic technology, applied in metal processing and other directions, can solve the problems of affecting cutting accuracy, easily damaged materials, troublesome materials, etc., and achieve the effects of high cutting accuracy, damage prevention and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

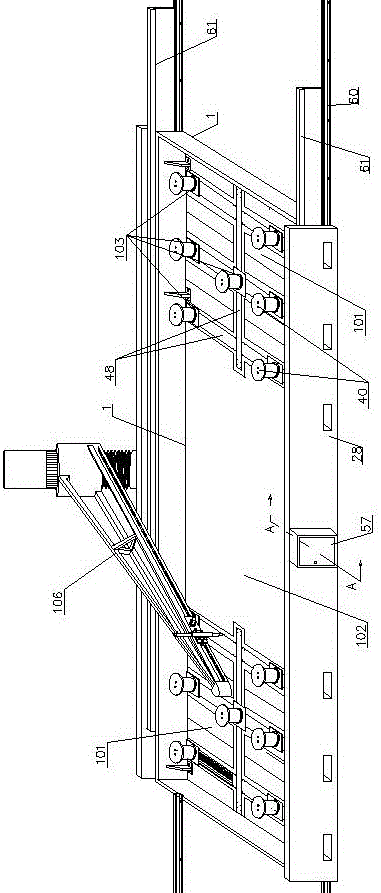

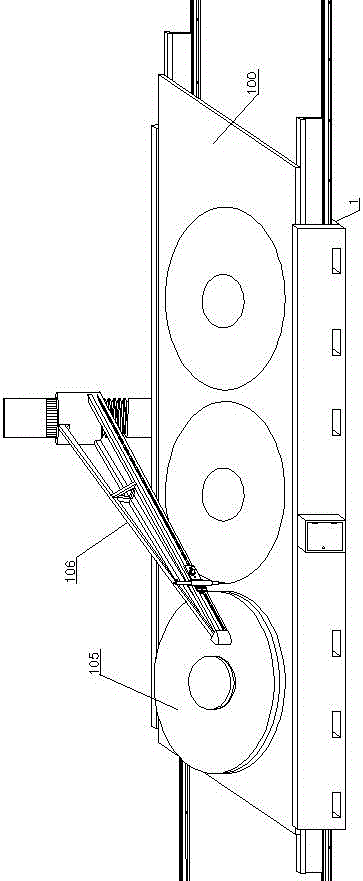

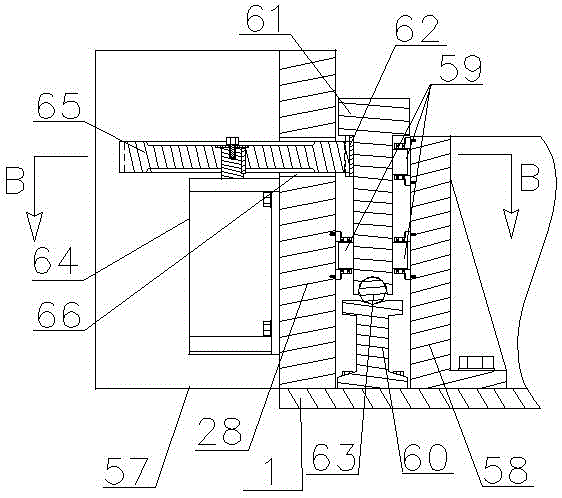

[0032] see Figure 1 ~ Figure 2 , the present embodiment includes a base plate 1, two sides of the base plate 1 are provided with two slide plates 61 with the same height and parallel to each other, the slide plate 61 is provided with a slide plate driving device, and the slide plate drive device is installed on the base plate 1. The base plate 1 includes support areas 101 at both ends and a cutting area 102 in the middle, and the support area 101 is equipped with several support devices 103; the support devices 103 include a base 29, a horizontal moving device 104, a cylinder 39, a piston rod 36. The top plate 40, the horizontal moving device 104 is installed on the base 29, the cylinder 39 is fixed with the horizontal moving device 104, one end of the piston rod 36 is fixed with the piston in the cylinder 39, and the other end passes through the top of the cylinder 39 and is fixed with the top plate 40 ; The top boards 40 in all supporting devices 103 are located on the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com