Assembly rack

An assembly frame and assembly part technology, applied in the field of aero-engines, can solve the problems of difficult installation angle conversion, easy damage to the installation surface, inconvenient turning of parts, etc., and achieve the effects of improving assembly quality, convenient positioning, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

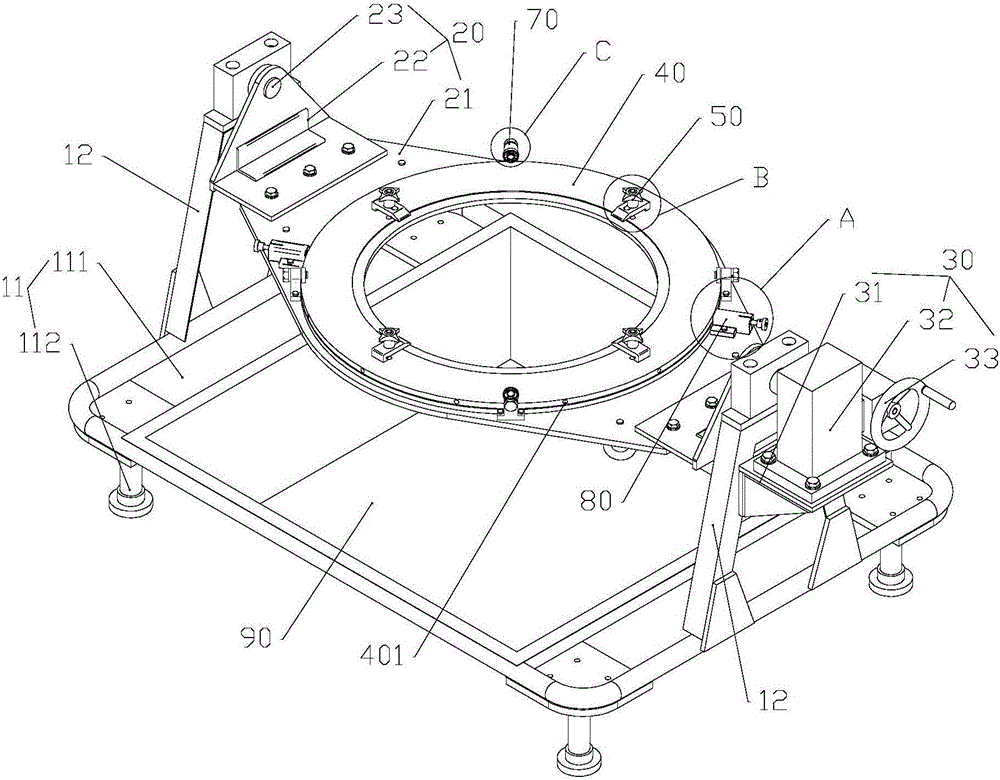

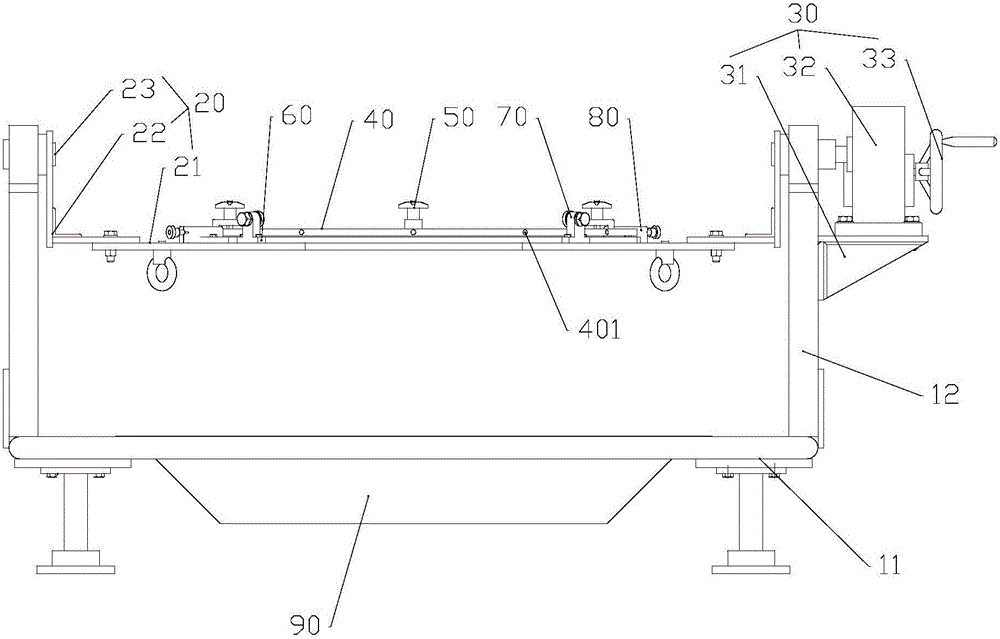

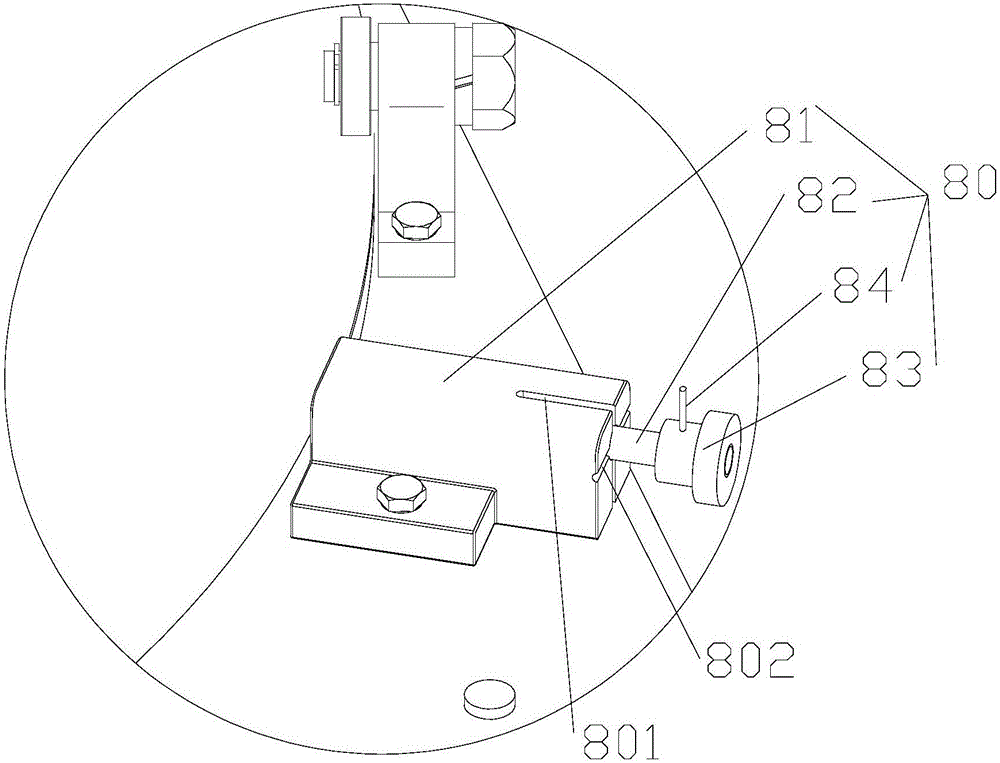

[0027] refer to figure 1 , the preferred embodiment of the present invention provides an assembly frame, including a support frame 10 supported on the working ground, a mounting seat 20 is rotated on the support frame 10, and the mounting seat 20 is connected to drive it to make any angle around a fixed axis. The overturned driving member 30 is disposed on the supporting frame 10 . The mounting seat 20 is provided with a turntable 40 for installing the parts to be assembled, and the turntable 40 is rotated relative to the installation seat 20. The turntable 40 is provided with multiple groups of pressing members 50 for pressing and fixing the parts to be assembled and the turntable 40. The group pressing members 50 are arranged at intervals along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com