Foamed cotton double-cutter cut-off machine

A technology of cutting machine and foamed cotton, which is applied in the direction of metal processing, etc., can solve the problems of affecting the cutting process, affecting the environment of the processing workshop, rough cutting surface, etc., and achieves convenient installation, production and operation, improved cutting quality, and efficient cutting process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

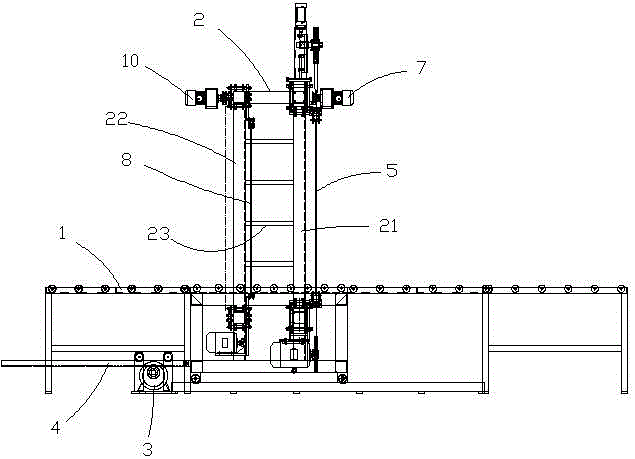

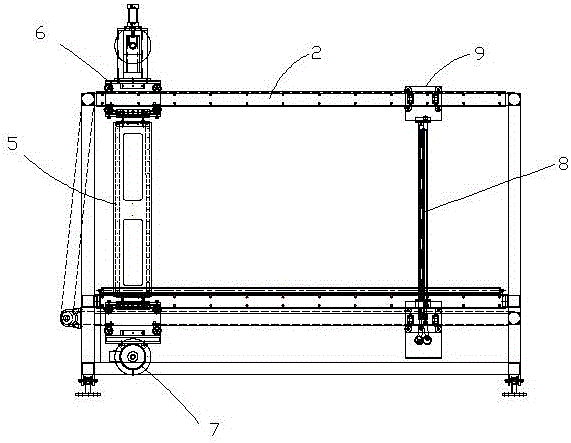

[0015] Such as figure 1 , figure 2 The foamed cotton double-knife cutting machine shown is mainly used for cutting and processing the foamed cotton after foaming. The cutting structure of cutting, the cutting mechanism is set as a cutting combination device with double knives, including an annular toothless knife cutting knife set, a serrated knife set, a support frame 2, a drive motor 3 and a linear transmission tooth placed at the bottom of the support frame 2 Bar 4, the transmission connection between the drive motor 3 and the linear transmission rack 4, and then the drive motor drives the support frame to move back and forth, so as to facilitate the adjustment of the cutting station of the support frame, the adjustment is convenient, fast and accurate, and the support frame 2 is fixed in the middle of the drive roller frame 1, the support frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com