Detection system and detection method for extrusion size of PVC pipe

A PVC pipe and size detection technology, applied in applications, household appliances, tubular items, etc., can solve problems such as affecting the quality of PVC pipes and reducing the accuracy of processing dimensions, and achieve the effects of reliable detection, quality assurance, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

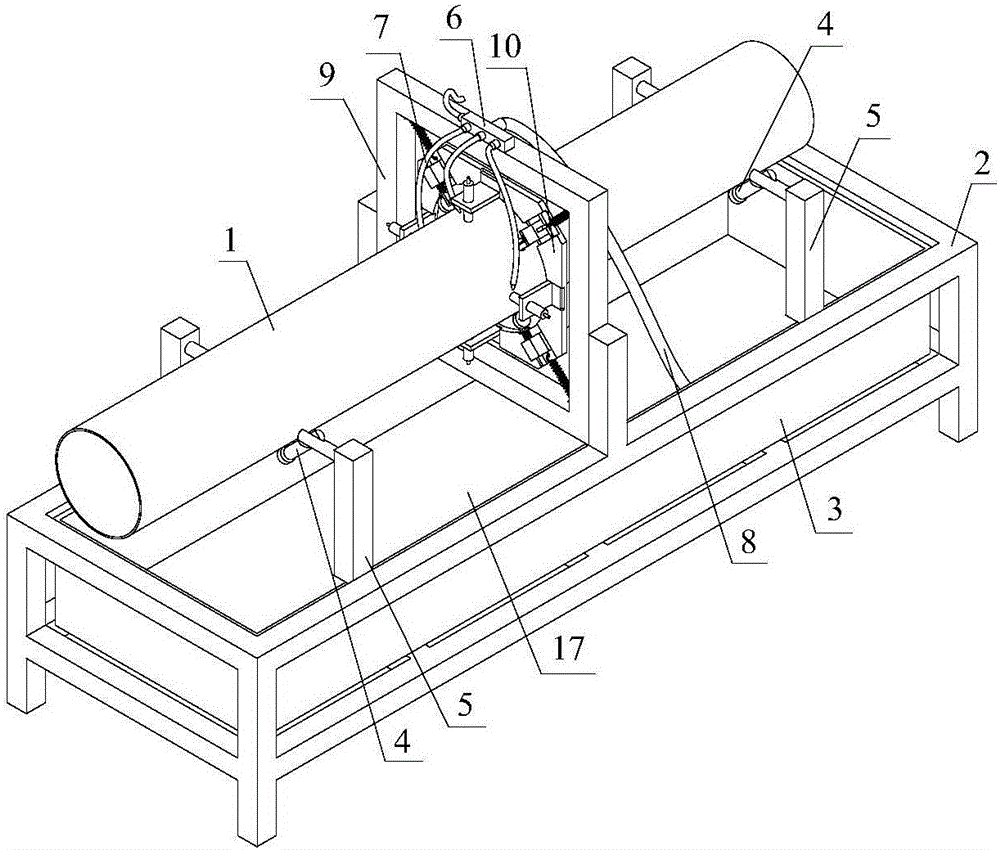

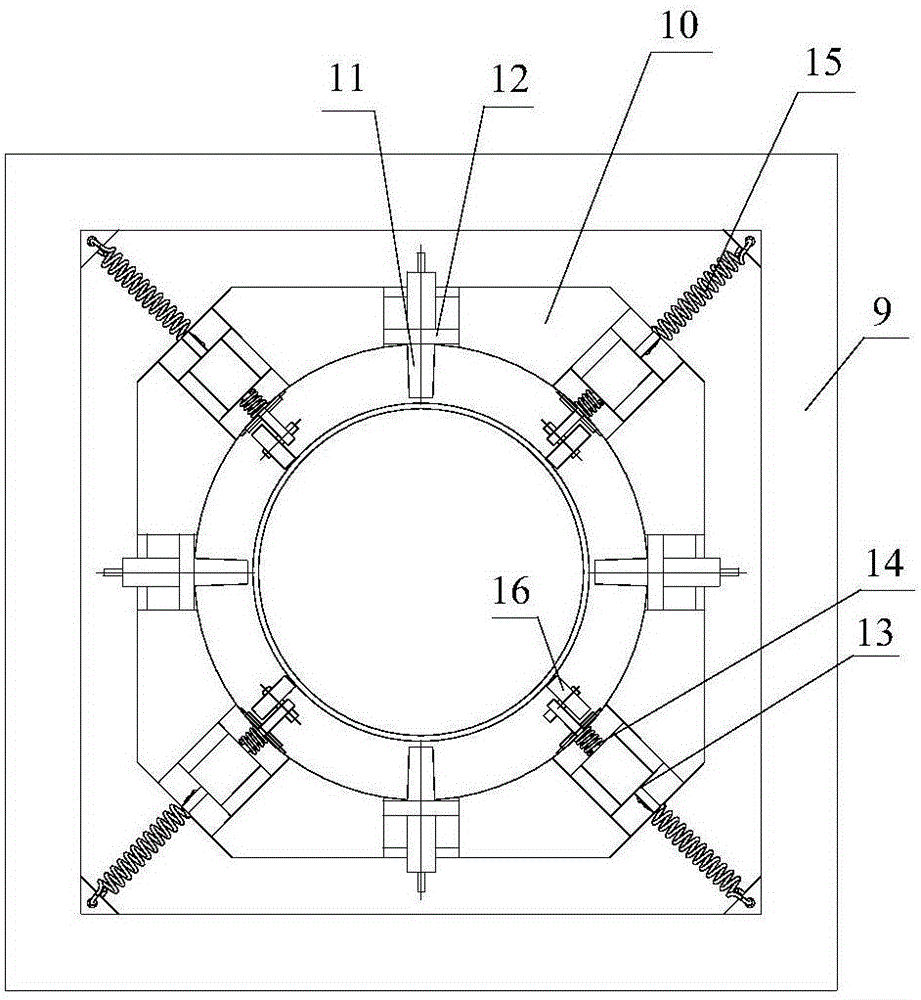

[0037] The system designed in the present invention for PVC pipe extrusion size detection system, combined with figure 1 and figure 2 As shown, it includes a fixed bracket 9 fixedly installed on the base 2, a probe holder 10 arranged in the central through hole of the fixed bracket 9, a through hole and a shower in the center of the probe holder 10 for the PVC pipe 1 to pass through. water device, and the center of the through hole of the probe holder 10 and the center of the through hole of the fixed bracket 9 coincide with the center of the concentric circle of the PVC pipe 1 cross section.

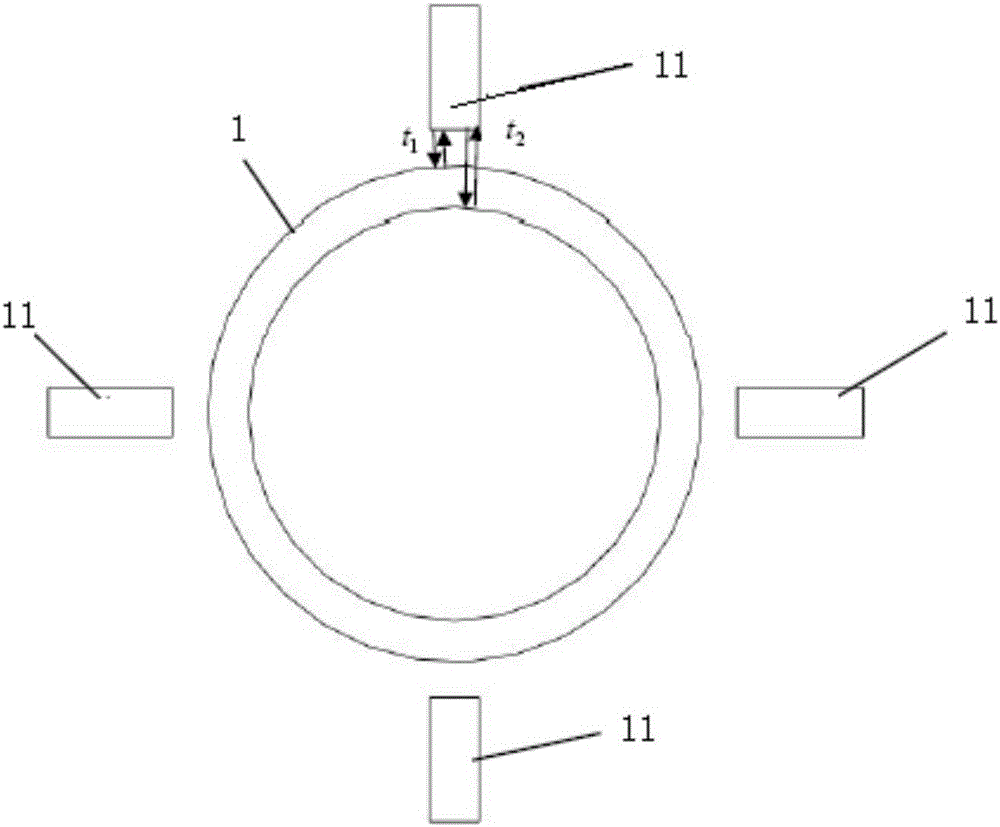

[0038] Among them: at least one group of probe groups is arranged on the probe holder 10, each group of probe groups includes two pairs of probe group units, each pair of probe group units includes two transceiver integrated ultrasonic sensor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap