A continuous molding and printing device for decorative gussets

A technology of printing and gusseting, applied in printing, application, printing machine and other directions, can solve the problems of time-consuming and laborious processing, difficult to meet the personalized decoration, single color of gusset structure, etc. The effect of improving molding efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

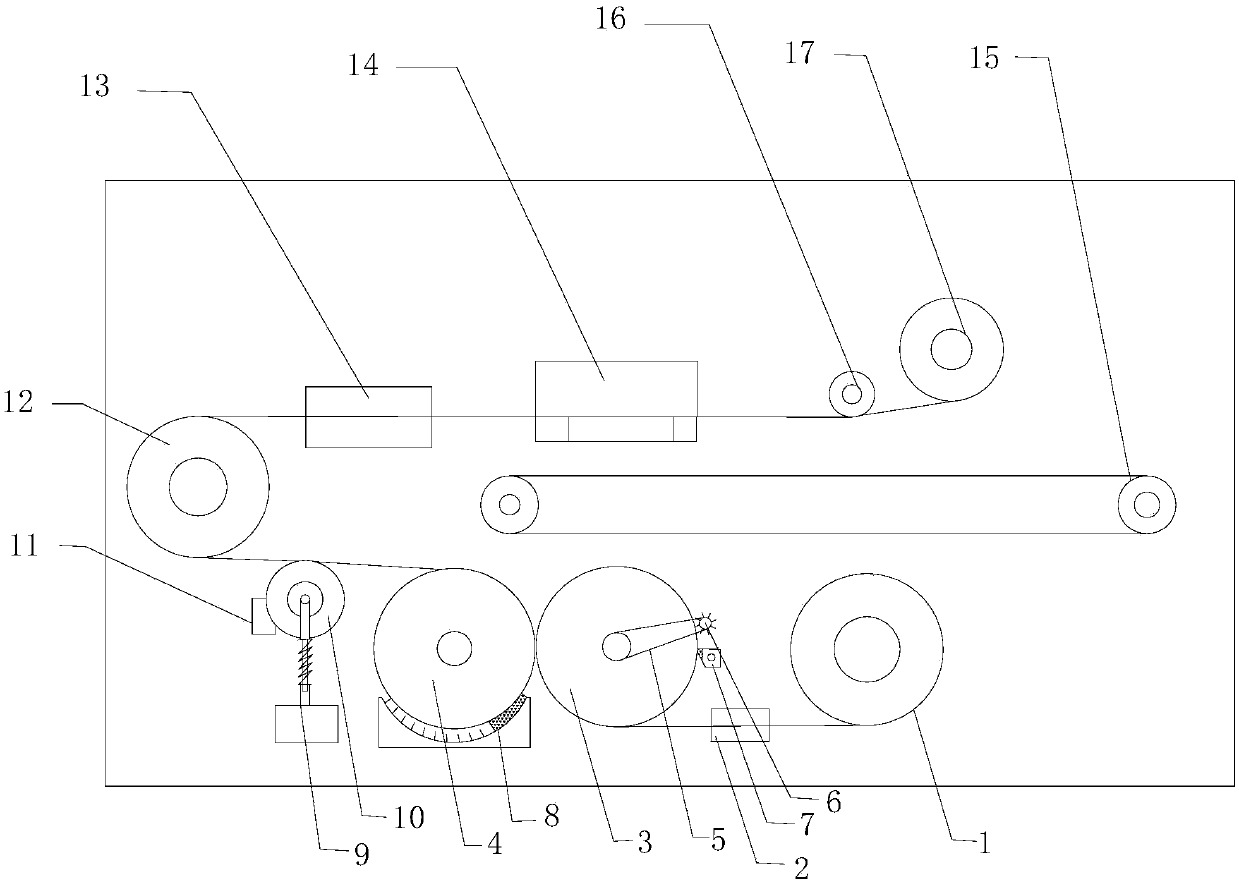

[0012] refer to figure 1 , the present invention is a continuous molding and printing device for gussets for decoration, comprising a discharge roller 1, a monolithic device 2, a first leveling roller 3, a second leveling roller 4, a transmission belt 5, an auxiliary cleaning brush 6, an auxiliary Scraping groove 7, cleaning bottom groove 8, elastic support 9, printing roller 10, character roller corrector 11, transition roller 12, heating and calibrating box 13, punching die 14, finished product conveyor belt 15, auxiliary positioning roller 16, take-up Material roller 17, the left side of described discharging roller 1 is provided with whole material device 2, and described whole material device 2 left side is provided with first leveling roller 3 and second leveling roller 4, and described first leveling roller 3 The right side is provided with an auxiliary cleaning brush 6, the auxiliary cleaning brush 6 is connected with the first leveling roller 3 through the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com