Press fit mechanism

A technology of pressing mechanism and lifting mechanism, which is applied in the direction of lamination, lamination device, lamination auxiliary operation, etc., can solve the problems of screen and shell position deviation, weak attachment, poor sealing effect, etc., and achieve structural Compactness, low cost, and the effect of preventing product misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

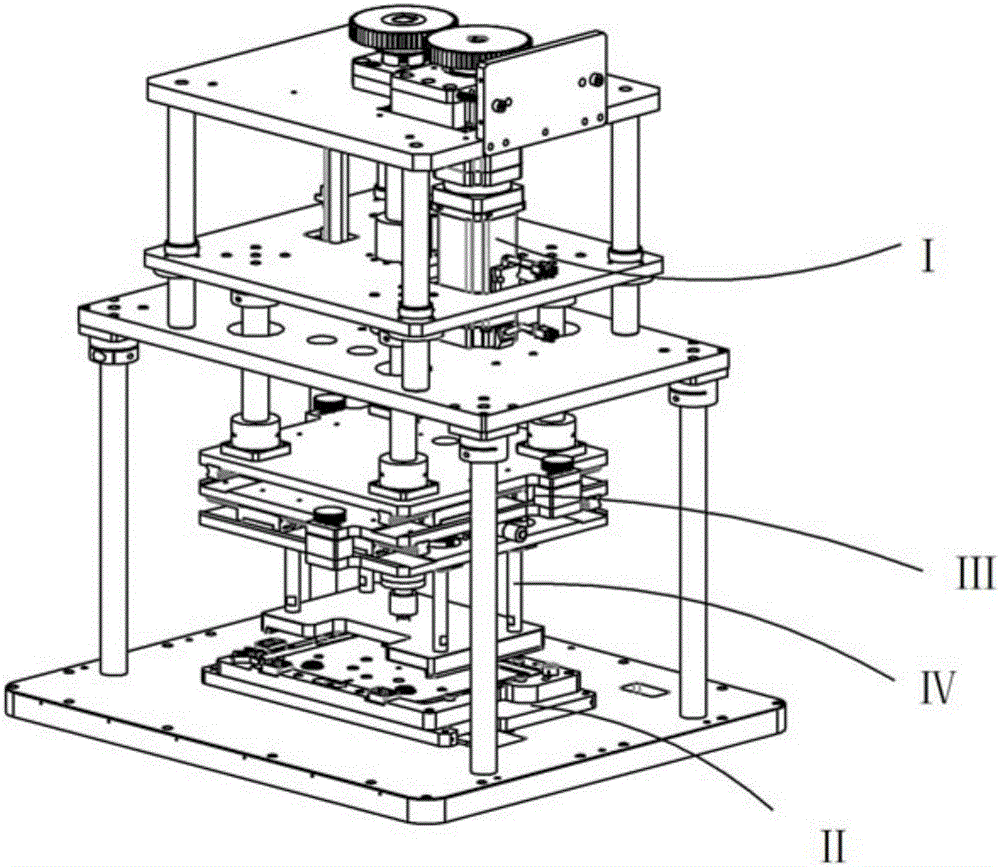

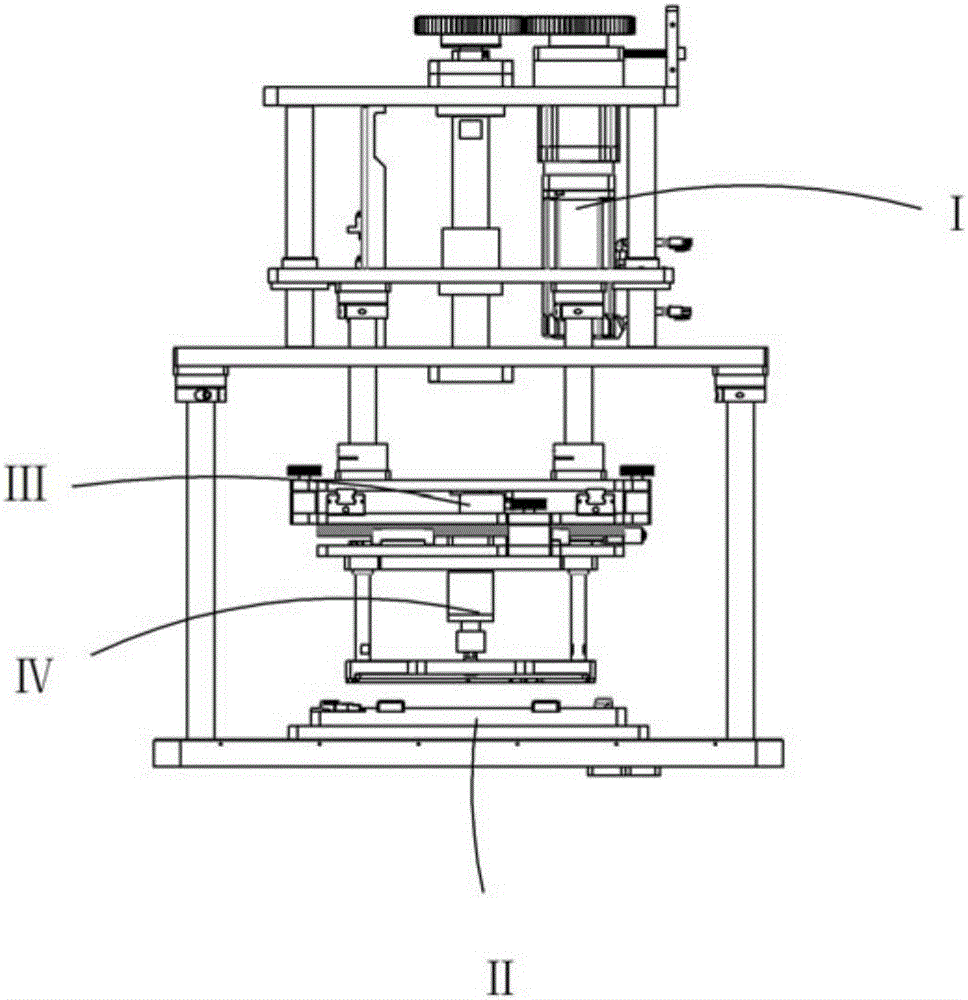

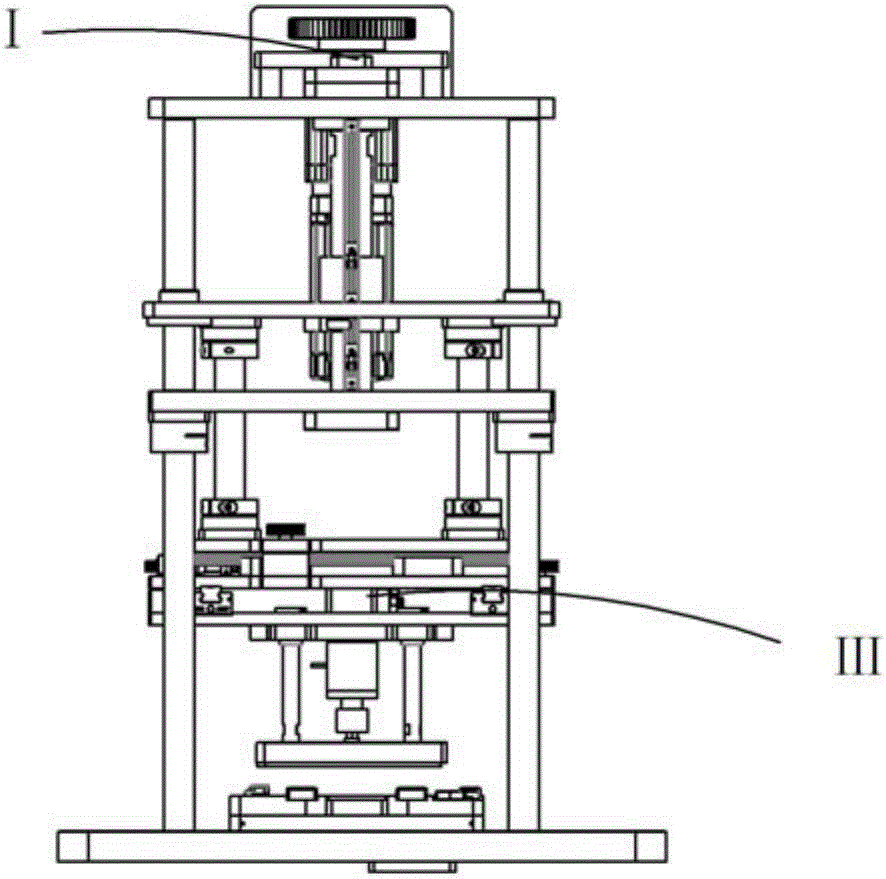

[0034] See attached Figure 1-14 , a pressing mechanism, including a lifting base plate 1 and a lifting mechanism I installed on the upper part of the lifting base plate, the lifting base plate is equipped with a carrier assembly II capable of correcting the carrier and preventing the products on the carrier from tilting; the lifting The lower end of the mechanism is equipped with an XY adjustment assembly III that can adjust the position of the pressing assembly in the X-axis direction and the Y-axis direction; the bottom of the XY adjustment assembly is equipped with a pressing assembly that can seal and compress the screen and the housing. Combined component IV.

[0035] The lifting mechanism includes a lifting support rod 2 installed on the top of the lifting base plate, a Z-axis base plate 3 installed on the upper part of the lifting support rod, and a lifting motor fixing plate 5 installed on the Z-axis base plate through the Z-axis guide rod 4; The lifting bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com