Printing machine

A technology for printing presses and racks, applied in printing presses, rotary printing presses, screen printing presses, etc., can solve the problems of inaccurate position adjustment, inaccurate material positioning, poor ventilation, etc., to improve practical performance, extend the Service life, the effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be further described below in conjunction with accompanying drawing.

[0081] The printing machine referred to in the present invention is mainly used in photoelectric industry printing and glass industry printing industries.

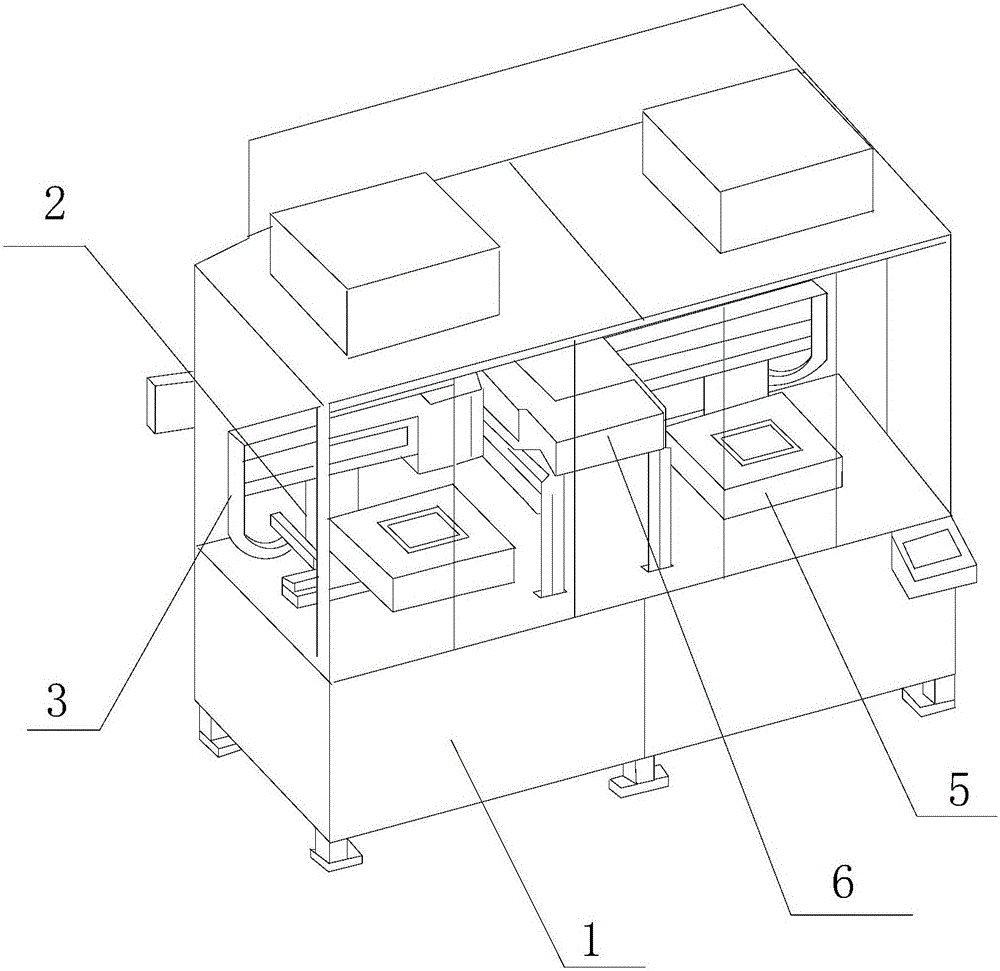

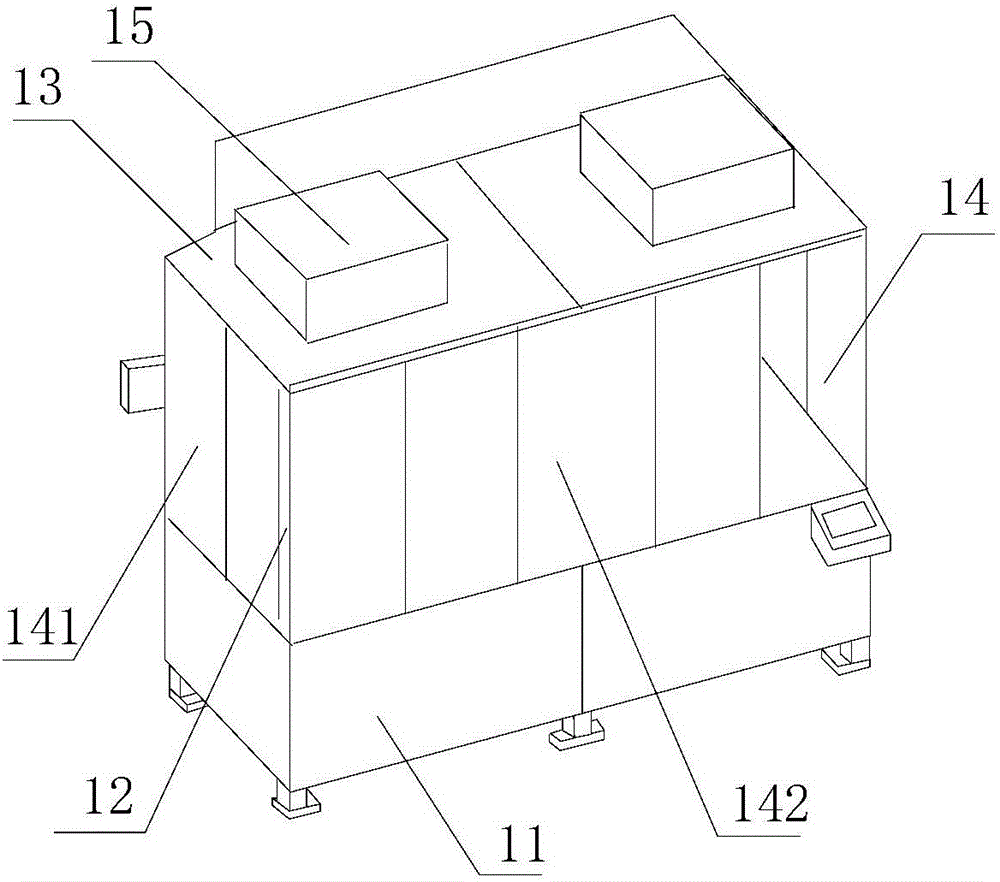

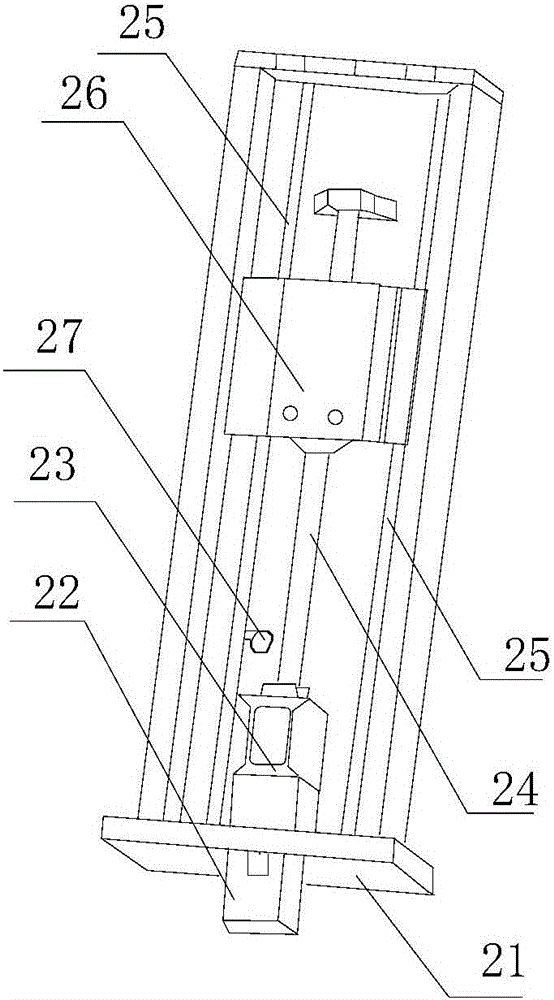

[0082] see Figure 1 to Figure 9 , the printing machine of the present invention includes a frame 1, and two column lifting mechanisms 2, two lateral movement mechanisms 3, two screen printing heads 4, two alignment platforms 5 and lenses respectively arranged inside the frame 1 Adjustment mechanism6.

[0083] Each column lifting mechanism 2 is fixed inside the frame 1, and is equipped with and drives a lateral moving mechanism 3 to vertically lift. Each lateral movement mechanism 3 carries and drives a screen printing head 4 to move laterally. Each alignment platform 5 is arranged directly below a screen printing head 4 , and the lens adjustment mechanism 6 is fixed in the middle of the two alignment platforms 5 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com