A powder spraying device for a printing machine

A printing machine and powder spraying technology, applied to printing machines, general parts of printing machinery, printing, etc., can solve problems such as increased production costs, too thick powder layer, easy ink adhesion, etc., to accelerate cooling speed and reduce use The effect of ensuring dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the drawings and embodiments, but it will not serve as a basis for limiting the present invention.

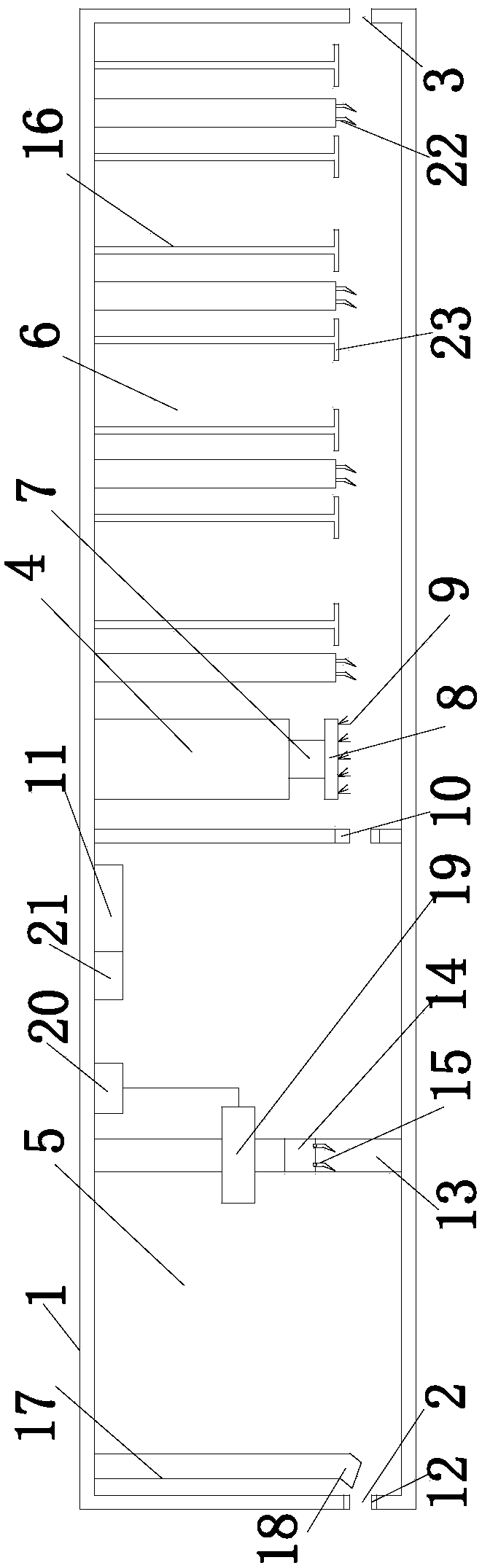

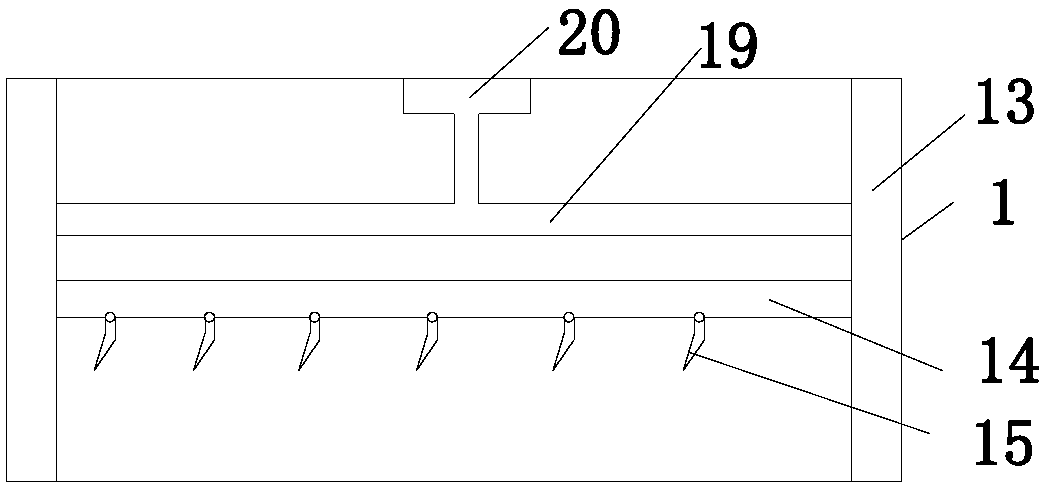

[0014] Examples. A powder spraying device for a printing machine, which is composed as figure 1 with figure 2 As shown, the housing 1 is included. One side of the housing 1 is provided with a paper inlet 2, and the other side of the housing 1 is provided with a paper outlet 3. The housing 1 is provided with a partition 4, and one side of the partition 4 is a spray nozzle. The powder chamber 5, the other side of the partition 4 is the dust removal chamber 6, the hydraulic rod 7 is provided under the partition 4, the lower end of the hydraulic rod 7 is provided with a brush fixing rod 8, and the brush fixing rod 8 is provided with a brush 9; The powder spraying chamber 5 is provided with a thickness sensor 10 on the side close to the partition 4, the thickness sensor 10 is connected with a controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com