Method for handling problem that anchor table gets stuck in anchor pulling test

A technology of anchor pulling test and processing method, which is applied in the direction of ship components, ships, transportation and packaging, etc., can solve the problem of increasing the workload of modifying the anchor pulling test site, passive or even difficult anchor pulling test work, and changing the cycle of anchor pulling test Long and other problems, to achieve the effect of shortening the anchor pull test cycle, reducing the workload of modification, and standardizing the processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

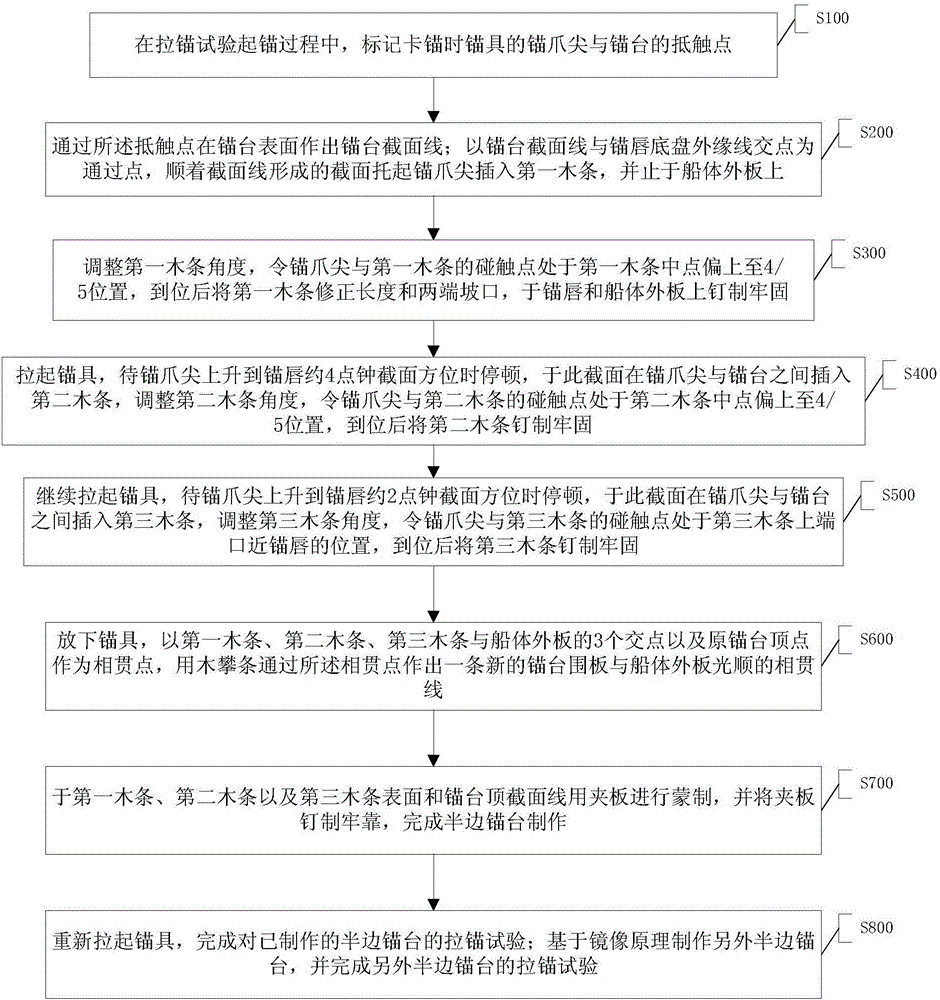

[0032] see figure 1 , a method for handling the stuck anchor of the anchor platform in the anchor pulling test proposed in the embodiment mainly includes the following steps S100 to S800:

[0033] S100. During the anchor lifting process of the anchor pulling test, mark the contact point between the anchor fluke tip of the anchorage and the anchor platform when the anchor is stuck.

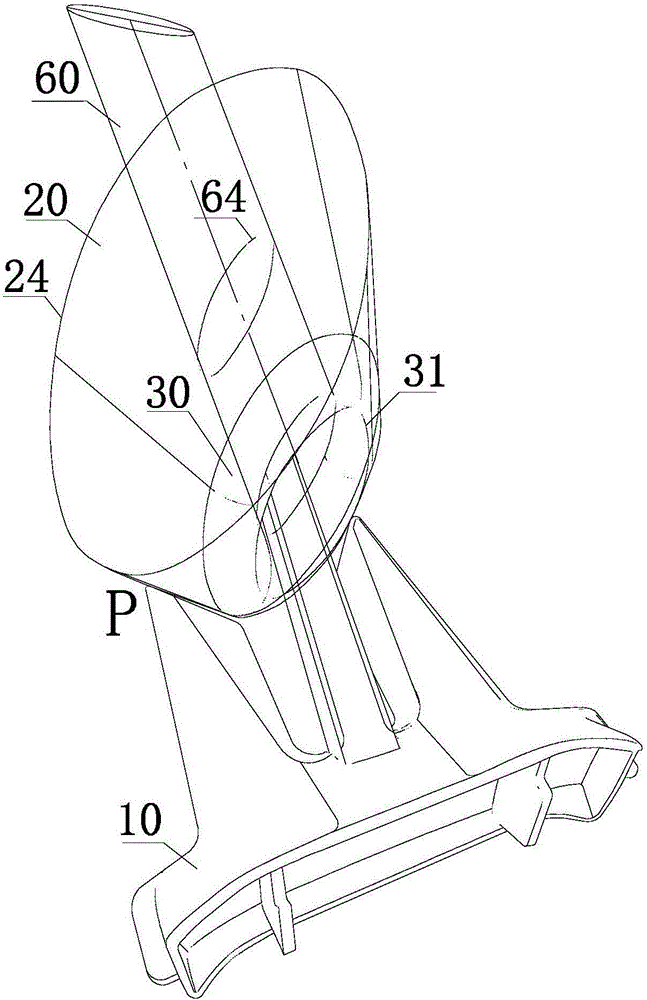

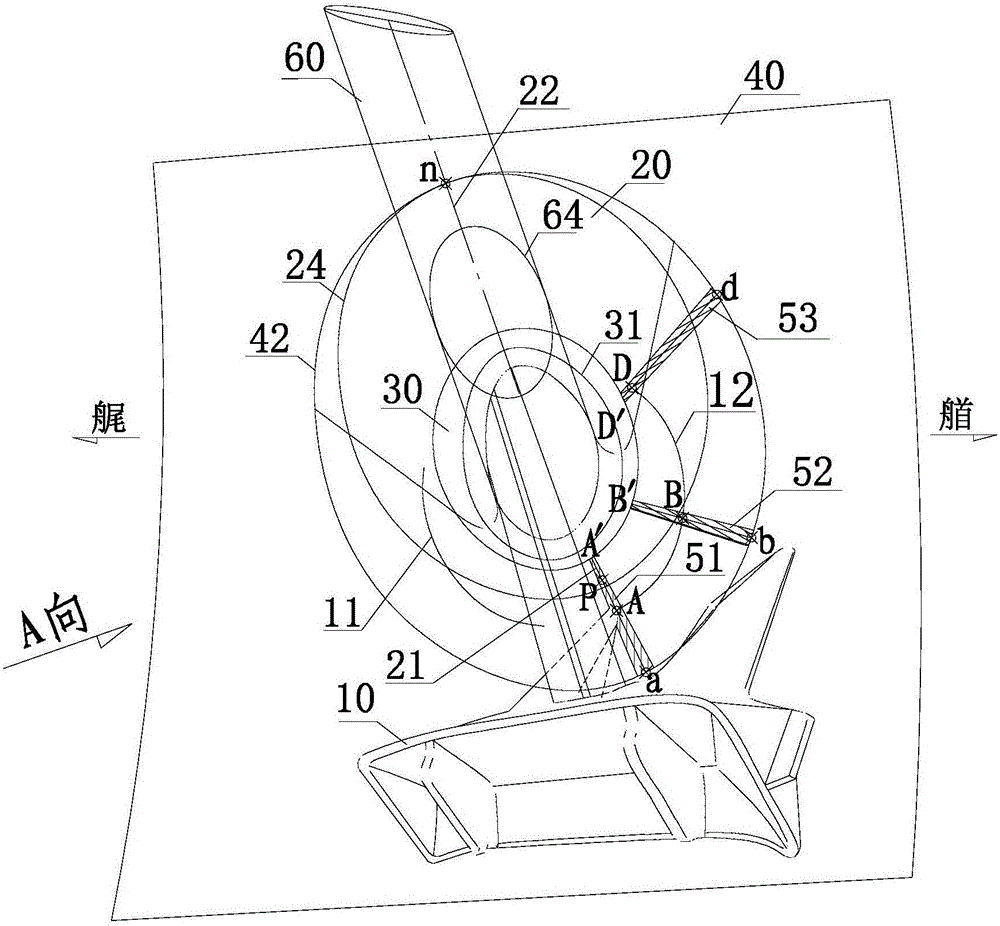

[0034] see figure 2 , during the anchor pulling test, the anchor fluke tip of the anchor 10 collides with the bottom end of the anchor platform 20, so that the anchor 10 cannot be pulled up further, that is, the anchor phenomenon occurs. Assuming that the collision point is P, mark the collision point P in step S100.

[0035] S200. Draw the cross-section line of the anchor platform on the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com