Belt conveyor corridor provided with flexibly sealed roofs

A belt conveying, flexible sealing technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problem of not meeting the requirements of use, achieve the effect of convenient cleaning and ensure the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

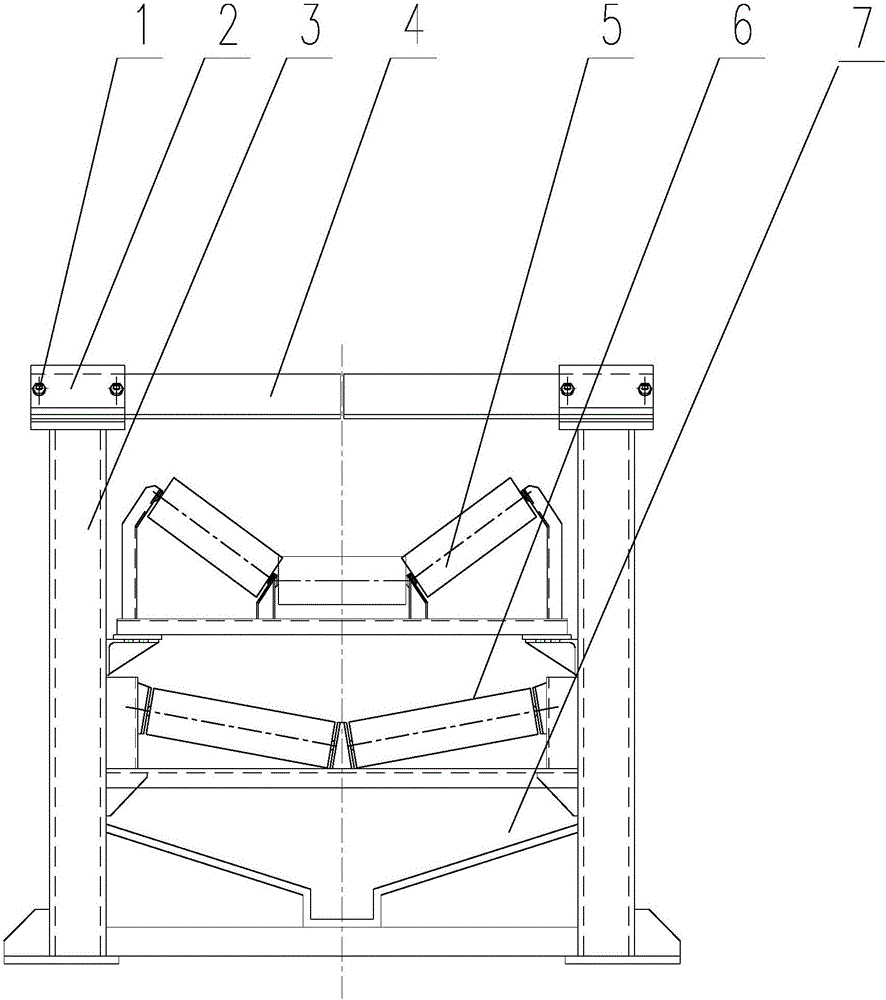

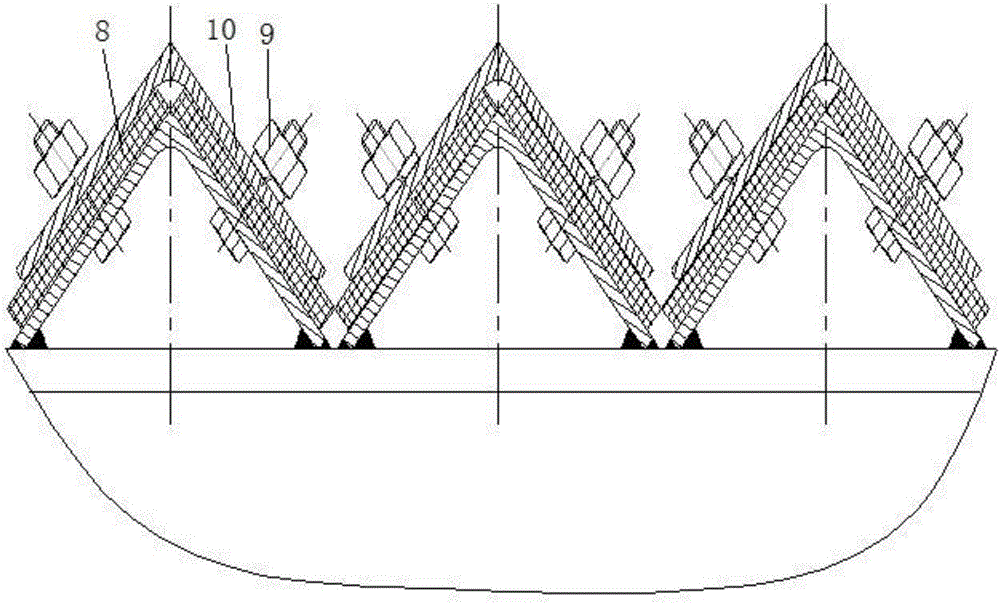

[0026] Such as Figure 1-2 As shown, a belt conveyor corridor with a flexible and sealed roof according to the embodiment of the present invention includes a corridor body, and the corridor body includes two connecting parts 1, two pressure plates 2, and two side plates symmetrically arranged 3 and two templates 4, the pressing plate 2 is fixed on the top of the side plate 3, and one end of the template 4 is connected to the pressing plate 2 through the connector 1. Template 4 includes a plurality of sub-templates 8, adjacent sub-templates 8 are connected end to end, and two adjacent sub-templates 8 are connected in a V shape or an inverted V shape, wherein the 2k+1th sub-template 8 and the 2k+2th sub-template 8 It is fixed by bolts 9 and 90° angle steel 10, wherein, k=0, 1, 2....

[0027] The upper roller group 5 and the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com