Feed plate device capable of preventing solder strip accumulation

A feeding tray and anti-soldering technology, which is applied in thin material processing, transportation and packaging, and coiling strips, etc., can solve the problems of thinking stop, feeding tray vibration, and laborious, etc., to achieve improved service life, long service life, avoid stacked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

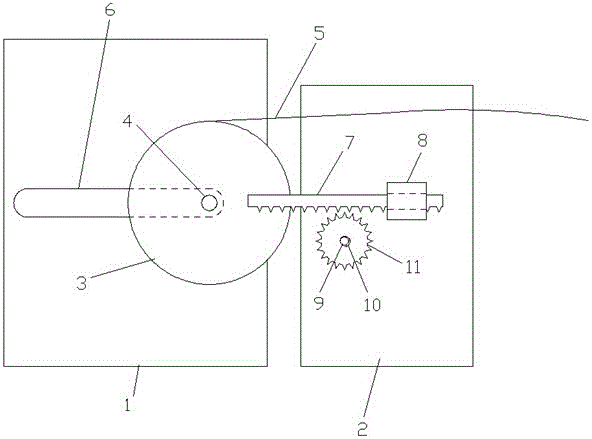

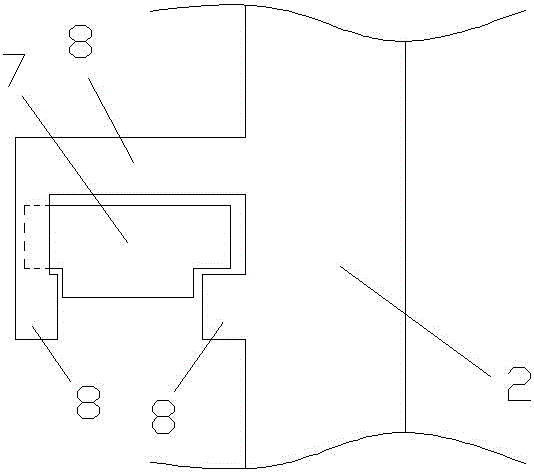

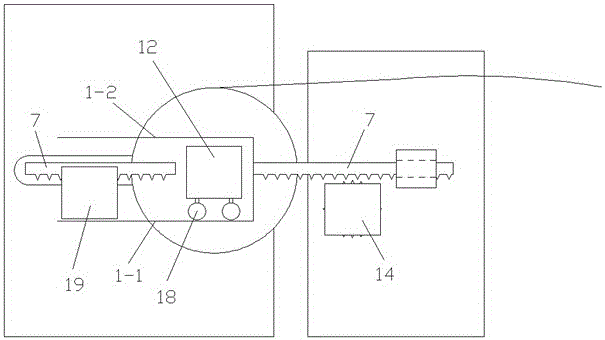

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0023] Such as Figure 1 to Figure 8As shown in the figure, a feeding tray device with anti-soldering tape accumulation includes a wire outlet device 1 and a remote device 2. The wire outlet device 1 is arranged on the left side of the remote device 2. The wire outlet device 1 includes a feeding tray 3. The disc 3 can rotate around the feeding disc shaft 4 to realize the conveyance of the copper strip 5, and the outlet device 1 is provided with a horizontal guide groove 6 that allows the feeding disc shaft 4 to translate; the resisting device 2 includes a rack and pinion mechanism , the rack 7 of the rack-and-pinion mechanism is arranged horizontally, the height of the rack 7 is consistent with the height of the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com