High-temperature and low-temperature resistant printing ink and preparation method thereof

A technology of high and low temperature resistance and ink resistance, applied in the field of printing ink, can solve problems such as use limitations and cracking, and achieve the effect of enhancing applicability, increasing viscosity, and improving high/low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

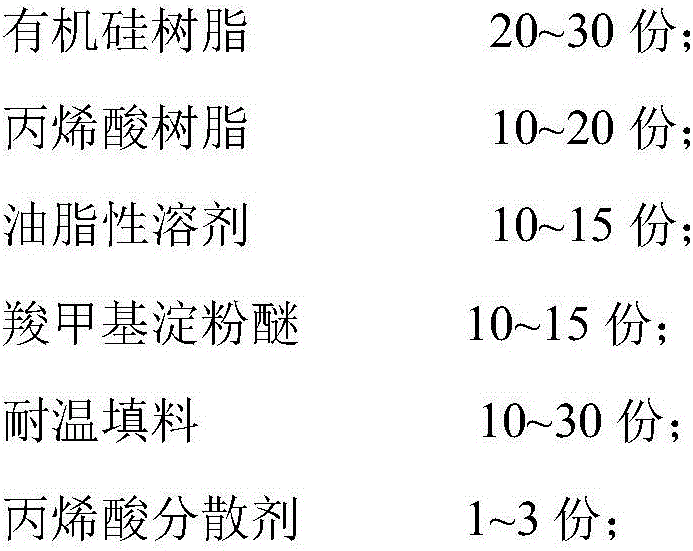

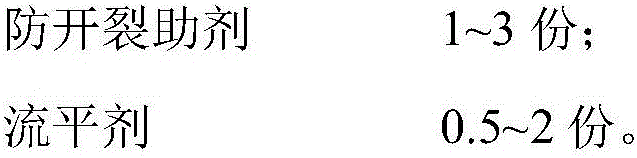

Method used

Image

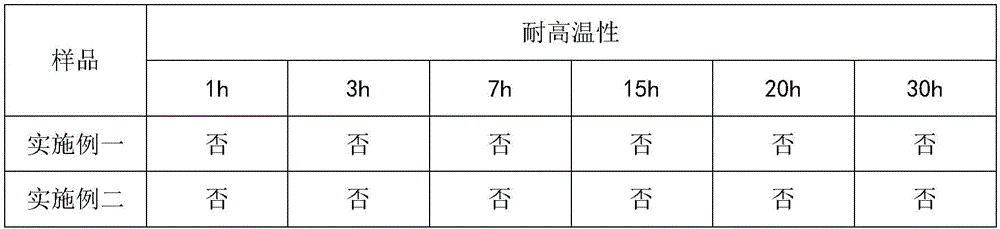

Examples

Example Embodiment

[0036] Example one:

[0037] (1) Place 10 parts of carboxymethyl starch ether, 6 parts of sepiolite, and 4 parts of vitrified microbeads in the grinder and grind for 5 minutes;

[0038] (2) 8 parts of methyl phenyl silicone resin, 8 parts of methyl silicone resin, and 4 parts of polyaryl silicone resin are pretreated by high-temperature heating at 80°C in advance;

[0039] (3) Put the mixed resin in (2), 10 parts of acrylic resin, and 10 parts of ethylene glycol butyl ether acetate in a reactor, and dissolve at 40°C;

[0040] (4) Add the ground material in (1) to the reactor in (3), add 1 part of acrylic dispersant, 0.5 part of polydimethylsiloxane and 1 part of nano-titanium dioxide and stir, stirring speed It is 150-200r / min, and a uniformly mixed blend is prepared.

Example Embodiment

[0041] Embodiment two:

[0042] (1) Place 12 parts of carboxymethyl starch ether, 10 parts of sepiolite, and 5 parts of vitrified beads in the grinder for 5 minutes

[0043] (2) Pre-heating 10 parts of methyl phenyl silicone resin, 10 parts of methyl silicone resin, and 5 parts of polyaryl silicone resin at 80°C in advance;

[0044] (3) Put the mixed resin in (2), 12 parts of acrylic resin, and 12 parts of dipropylene glycol butyl ether in a reaction kettle, and dissolve at 40°C;

[0045] (4) Add the ground material in (1) to the reaction kettle in (3), add 1.5 parts of acrylic dispersant, 1 part of polydimethylsiloxane and 1.5 parts of nano titanium dioxide and stir, stirring speed At 180r / min, a uniformly mixed blend was prepared.

Example Embodiment

[0046] Embodiment three:

[0047] (1) Place 12 parts of carboxymethyl starch ether, 13 parts of sepiolite, and 7 parts of vitrified microbeads in a grinder and grind for 5 minutes;

[0048] (2) 12 parts of methyl phenyl silicone resin, 10 parts of methyl silicone resin, and 5 parts of polyaryl silicone resin are pretreated by high temperature heating at 80°C;

[0049] (3) Put the mixed resin in (2), 15 parts of acrylic resin and 13 parts of rosin alcohol in a reaction kettle, and dissolve at 40°C;

[0050] (4) Add the ground materials in (1) to the reaction kettle in (3), add 2 parts of acrylic dispersant, 1.2 parts of polydimethylsiloxane and 1.8 parts of nano-titanium dioxide and stir, stirring speed At 200r / min, a uniformly mixed blend was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com