Unloading type t-type sheet pile breakwater enclosure

A technology of breakwaters and sheet piles, which is applied in the field of port and coastal engineering building structures, can solve problems such as safety and reliability doubts, complex structure types, and difficult construction, so as to reduce engineering costs, reduce wave reflections in front of embankments, The effect of small road foundation settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

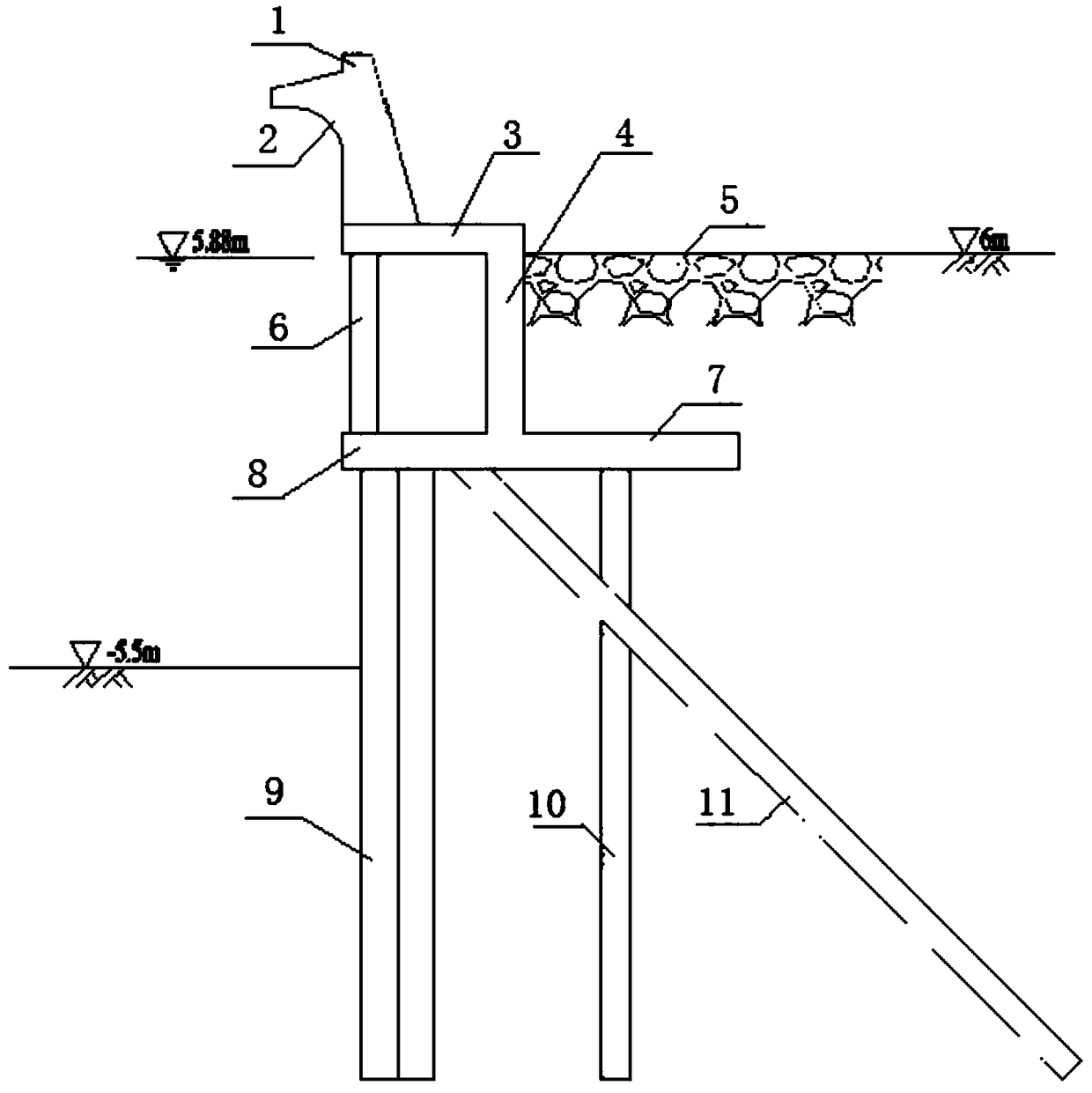

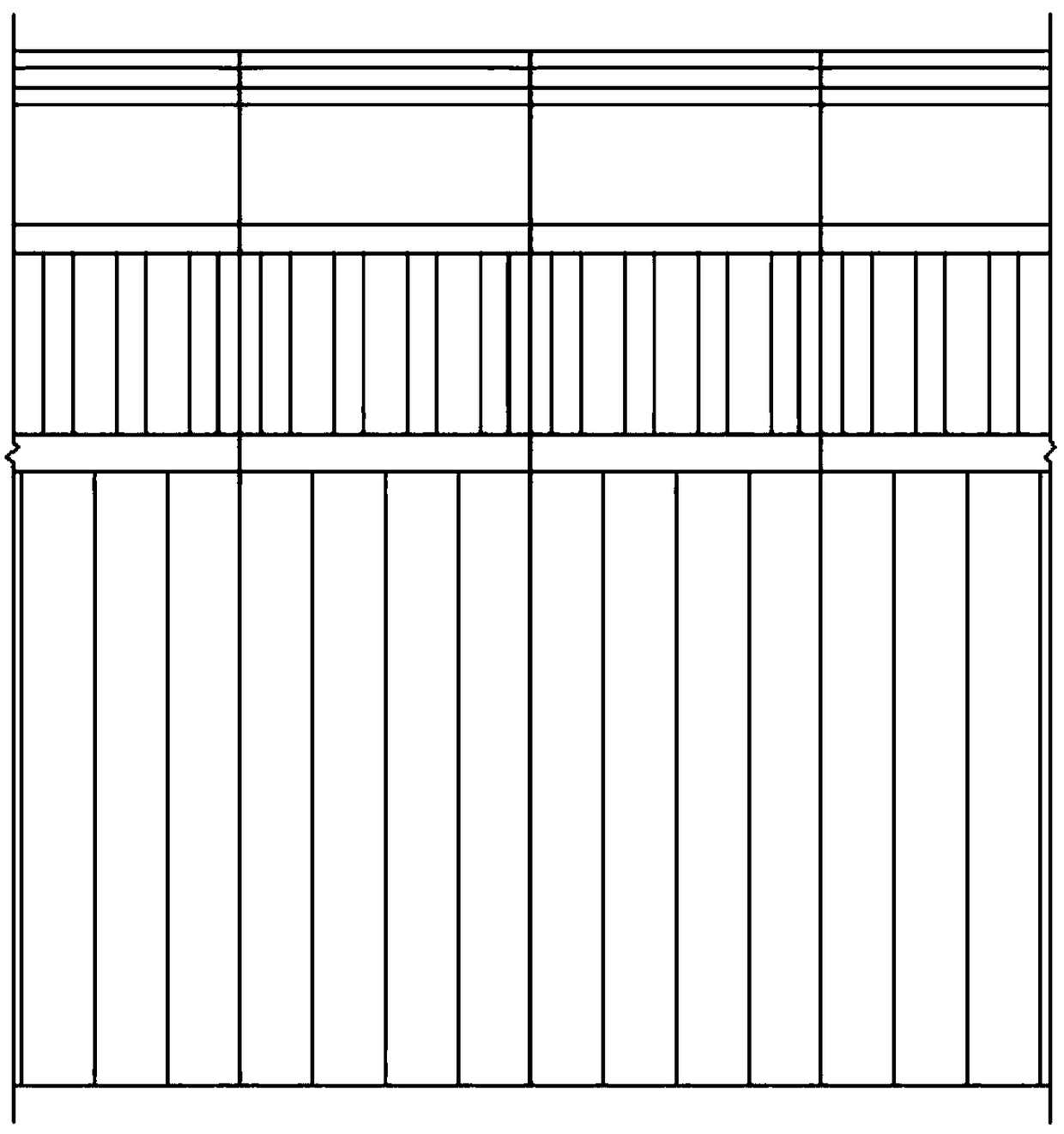

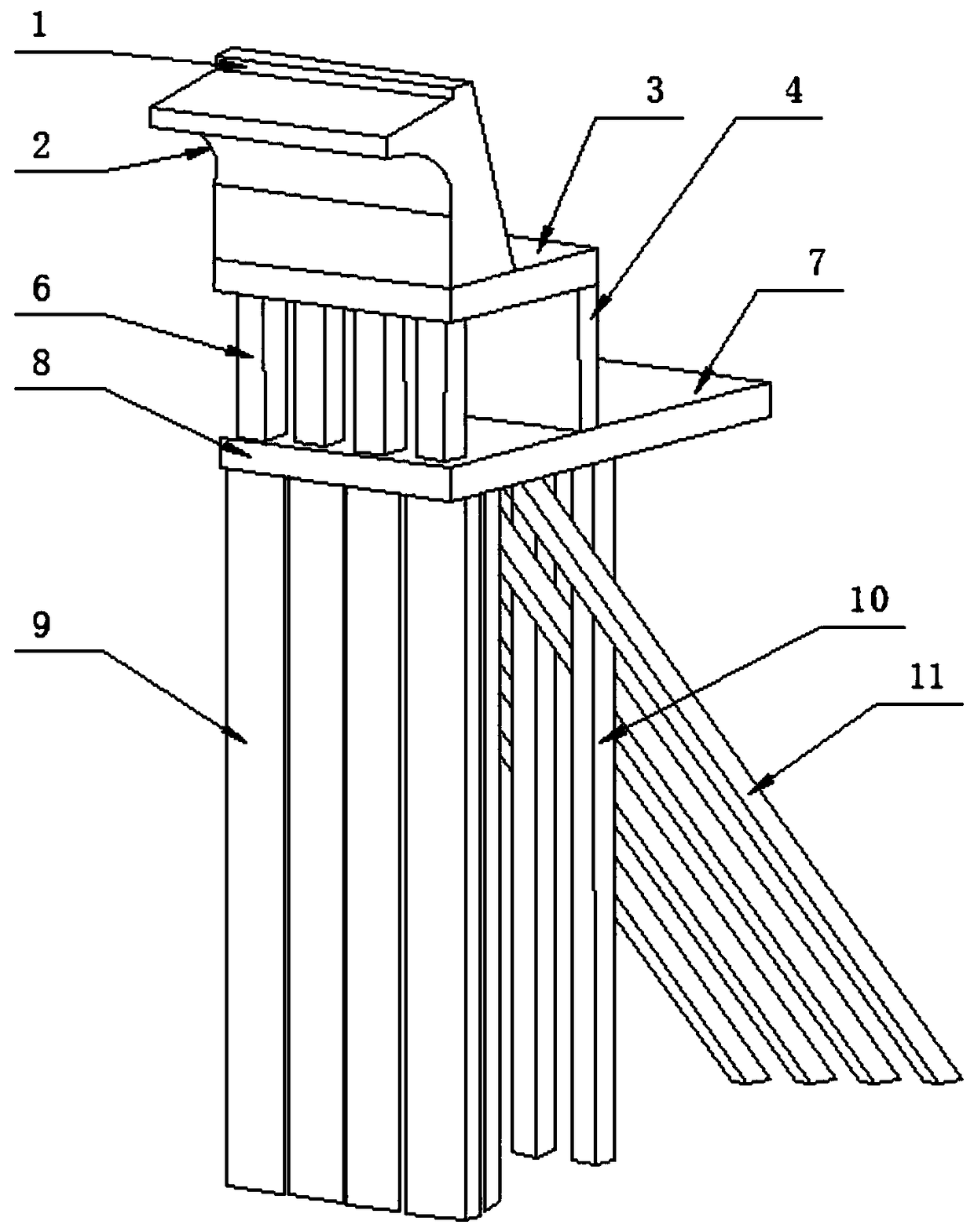

[0033] An unloading type T-shaped sheet pile breakwater enclosure consists of an upper anti-wave structure and a lower soil retaining structure. The anti-wave structure includes an arc-shaped anti-wave wall 2 and a fence-type wave-dissipating wall 6, and an arc-shaped anti-wave wall 2 is arranged on the upper part of the fence-type wave-dissipating wall 6. The soil retaining structure is composed of unloading boards, T-shaped sheet piles 9, curtain-type square piles 10, and cable-stayed anchor piles 11. The unloading board is composed of unloading bottom plates 8, unloading vertical plates 4 and unloading top plates 3. An unloading vertical plate 4 is arranged on the upper part of the bottom of the load, and an unloading top plate 3 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com