Wave weakening structure for bridge tower

A technology for bridge towers and wave elimination, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as cumbersomeness, huge structure, and difficulty, and achieve the effects of low cost, wave force reduction, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

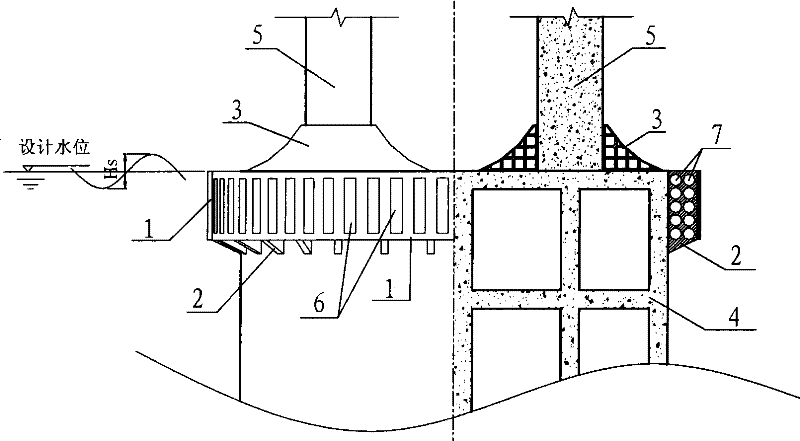

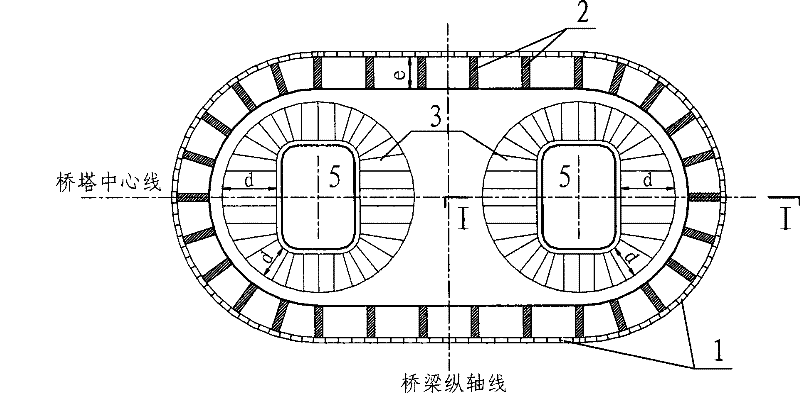

[0026] Now in conjunction with accompanying drawing the present invention is described in further detail:

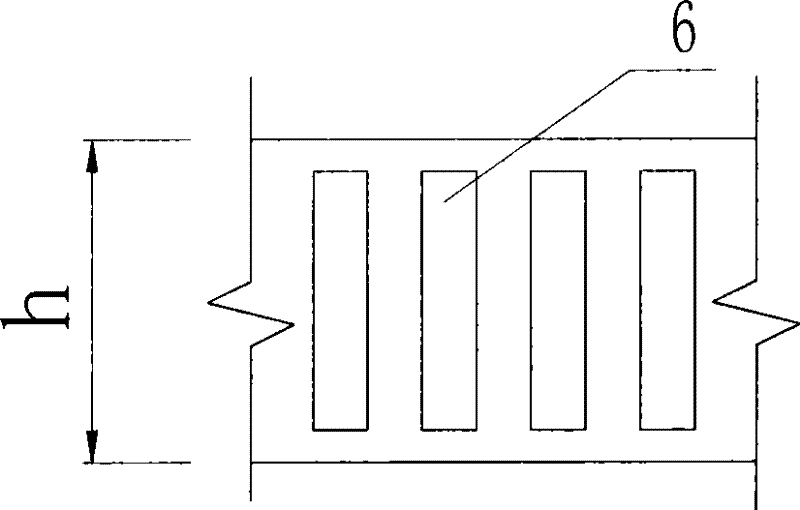

[0027] The invention is a wave dissipation structure for a bridge tower, which is composed of a sleeve 1, a support plate 2 and a wave guiding block 3 with a concave curved surface. The sleeve 1 is arranged around the bridge tower foundation 4 through the support plate 2, and is arranged in a ring on the plane (such as figure 1 , 2 shown); the height of the sleeve 1 is 1.5 to 2.0 times the design wave height, and is provided with a vertical rectangular through hole 6 (such as image 3 shown), the porosity is 30% to 50%. The sleeve 1 is fixed on the bridge foundation 4 through the support plate 2, the support plate 2 is trapezoidal, and the bottom is h 1 , the top edge is h 2 , the height is f, where: h 2 =h, f=e (as Figure 4 shown). Open round through hole 7 on support plate 2 (as Figure 4 shown), the opening ratio is 40% to 60%, and these through holes can ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com