Fabricated high-altitude protective shed used for building construction and assembling method thereof

A high-altitude protection and building construction technology, which is applied in the direction of construction, building structure, and building materials processing, can solve the problems of protective sheds, protective sheds, etc., and achieve the effects of long service life, strong practicability, and ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

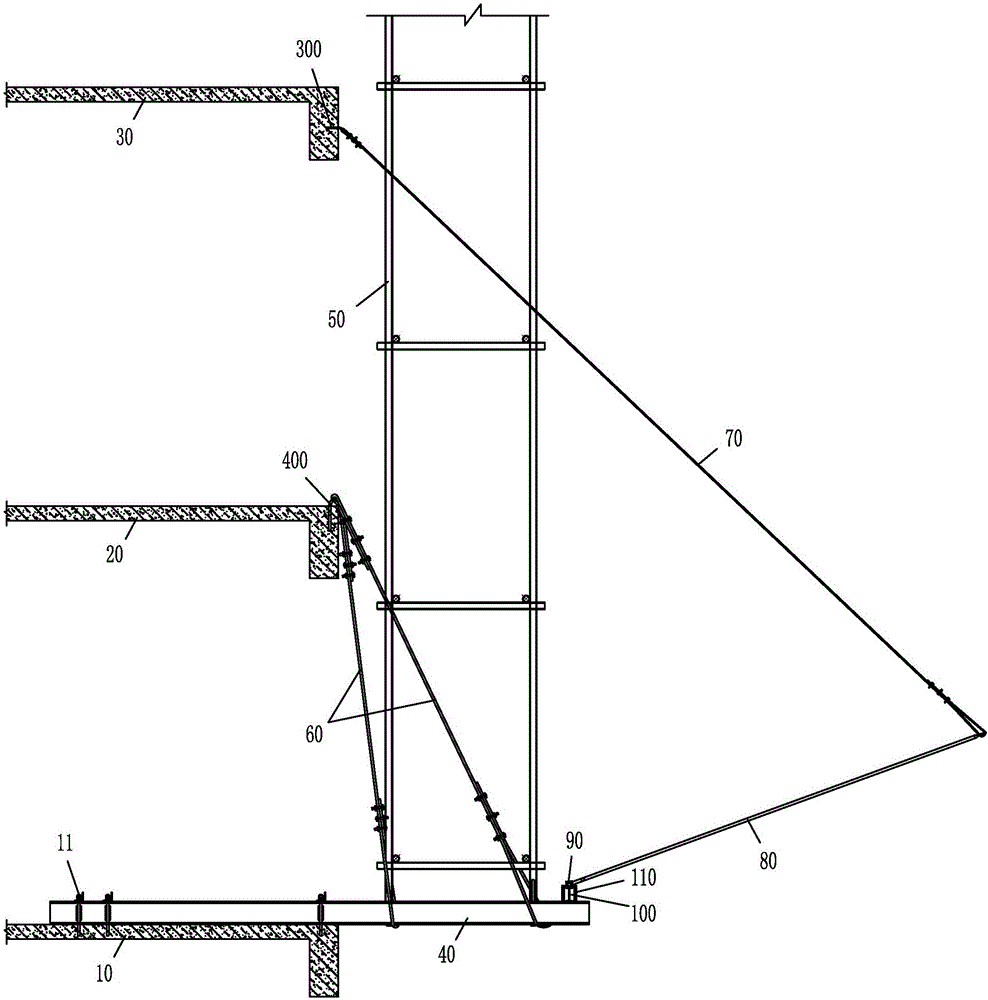

[0033] The prefabricated high-altitude protective shed for building construction of the present invention is assembled on the three floors of the upper floor 30, the middle floor 20 and the lower floor 10 and is outside each floor. In the vertical direction, the main building structure includes several floors. In actual implementation, three consecutive floors can be selected, such as figure 1 , the selected three consecutive floors are the upper floor 30, the middle floor 20, and the lower floor 10 from top to bottom.

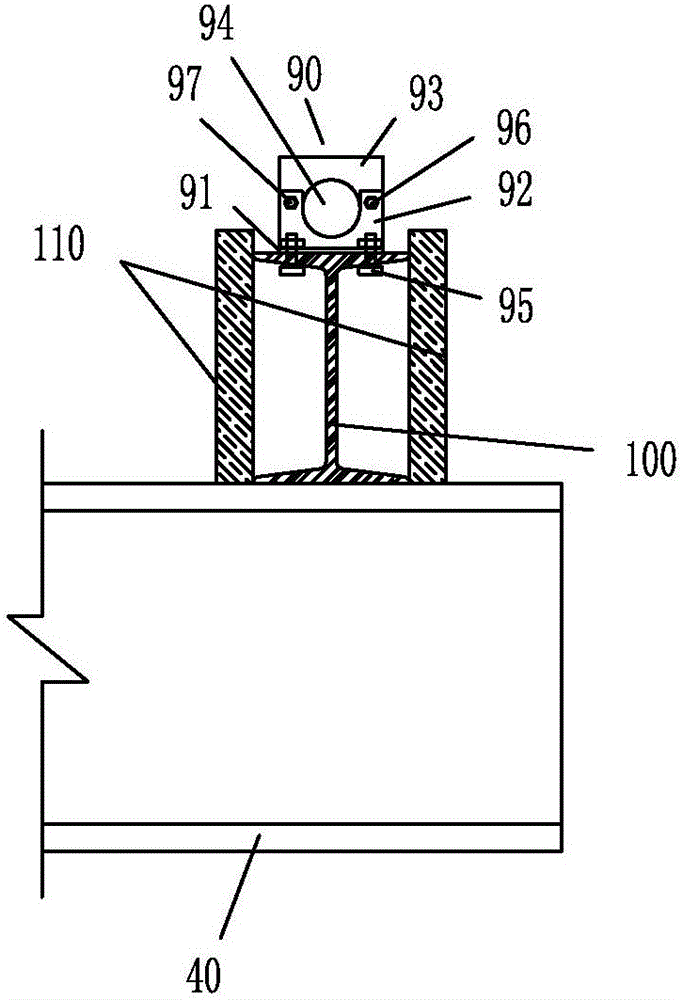

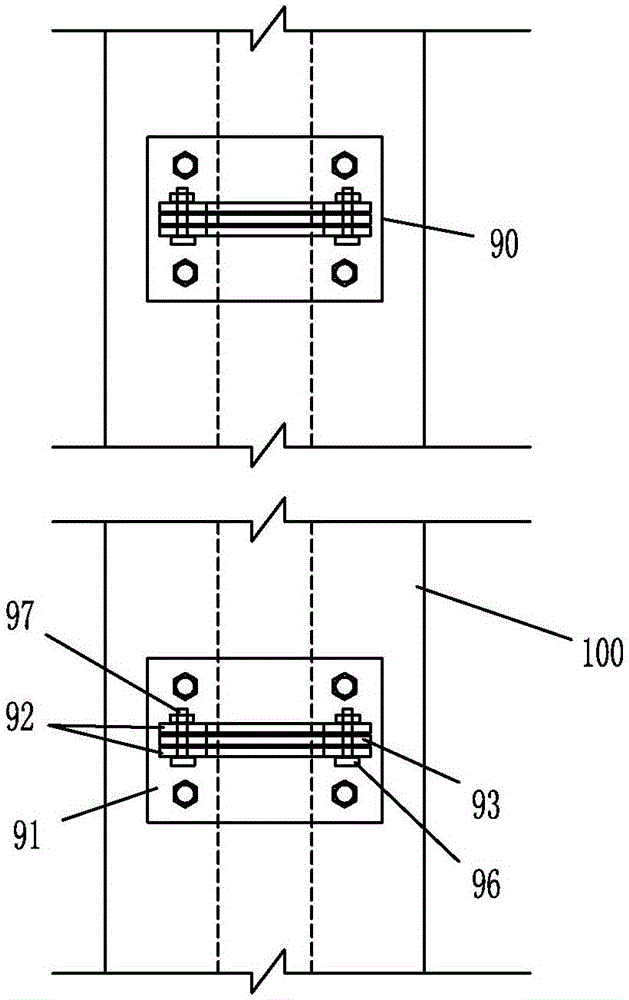

[0034] Such as Figure 1 to Figure 4 As shown, the prefabricated high-altitude protective shed for building construction of the present invention includes several cantilever beams 40 fixed on the lower floor 10 by ground bolts 11, each cantilever beam 40 can be arranged in parallel at intervals, and each cantilever beam 40 protrudes The part outside the lower floor 10 is fixed with the outer edge of the middle floor 20 through the outer frame unloading wire r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com