Dust removal equipment suitable for dust control over coal mining face

A technology for dust removal equipment and working face, which is applied in the direction of earthwork drilling, cutting machinery, etc., can solve the problems of high dust prevention cost, low dust reduction efficiency, large water consumption, etc., to prevent coal dust explosion, high dust removal efficiency, and dust removal. Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

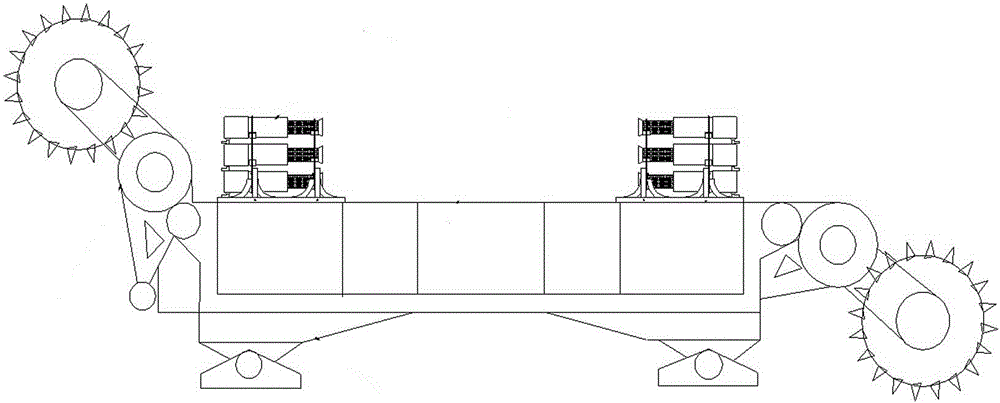

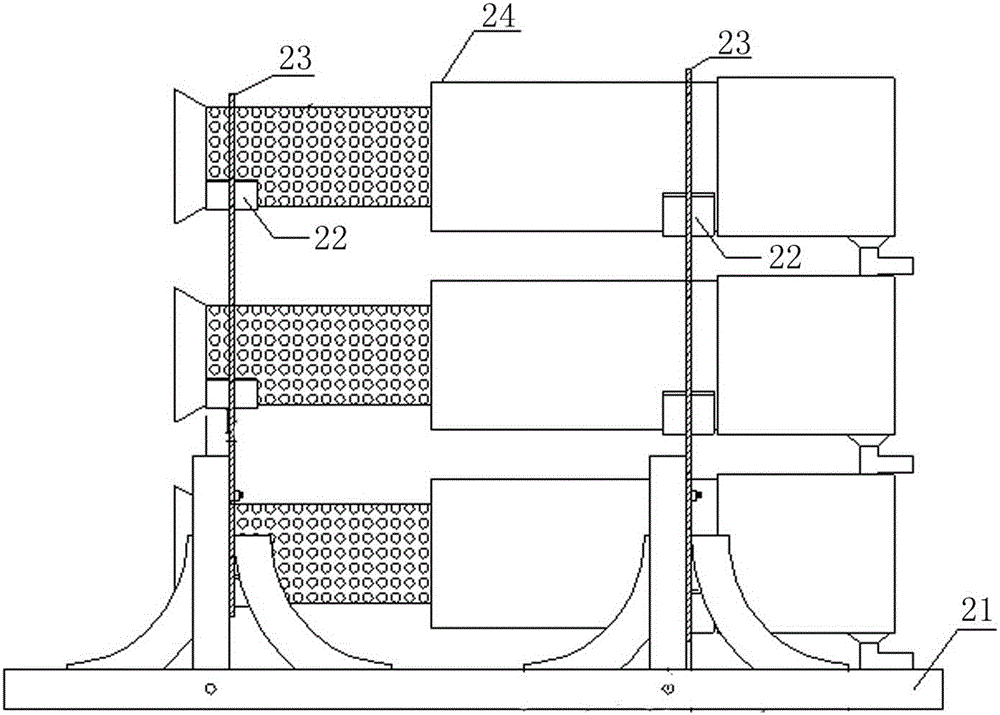

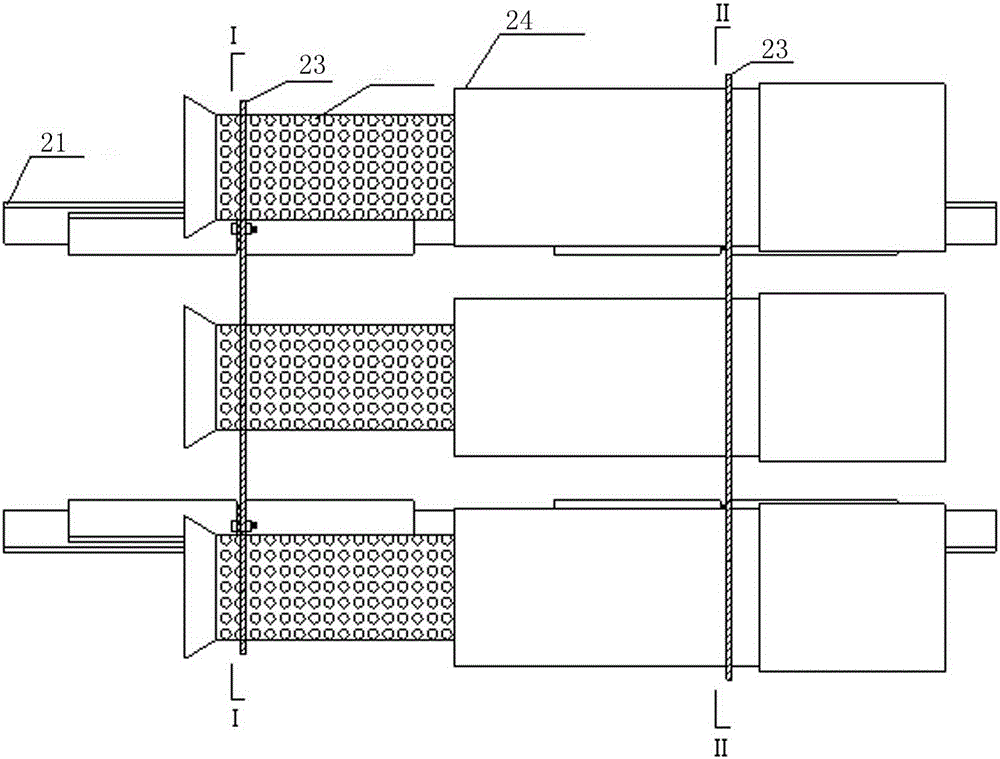

[0037] Such as figure 2 , 3 The dust removal equipment suitable for coal mine dust treatment shown in 4 and 5 includes angle steel base 21, steel frame 23 and 4 sets of dust removal air ducts 24. The dust removal air ducts 24 are arranged horizontally and evenly distributed in a ring shape and consist of a steel frame 23 Fixed, the bottom of the steel frame 23 is connected with the angle steel base 21, and the dust removal air cylinders 24 are connected by a spray pipe 26, and a water valve 25 is provided on the spray pipe 26.

[0038] The dust removal air cylinder has a stepped structure, and includes a first-stage cylinder 243, a second-stage cylinder 245, and a third-stage cylinder 246 whose diameters gradually increase. The end of the first-stage cylinder 243 is provided with a dust-catching cover 241. 243 is provided with a nozzle 242 connected to the spray pipe 26, a cyclone 244 is provided in the secondary cylinder 245, a filter screen 247 is provided in the tertiary cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com