A Multi-point Yield Grouting Anchor Rod Used for Supporting Deep Sectional Fractured Roadway

A technology for roadway support and grouting bolts, which is used in the installation of bolts, construction, mining equipment, etc. problems such as the best period to achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

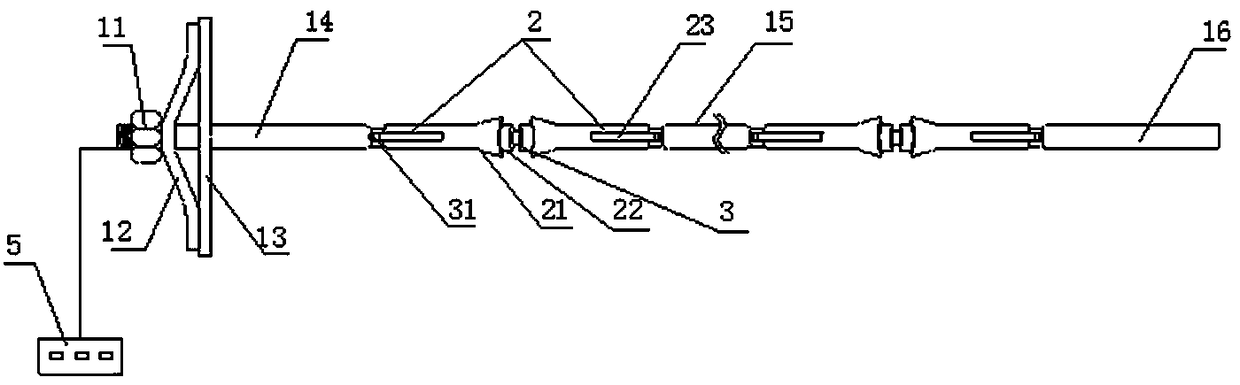

[0023] Such as figure 1 As shown, a multi-point yielding grouting anchor used for support of cracked roadways in deep partial areas includes anchor rod body 1, yielding grouting connector 2, constant resistance yielding rod 3, retractable grouting soft Tube 4 and grouting indicator 5.

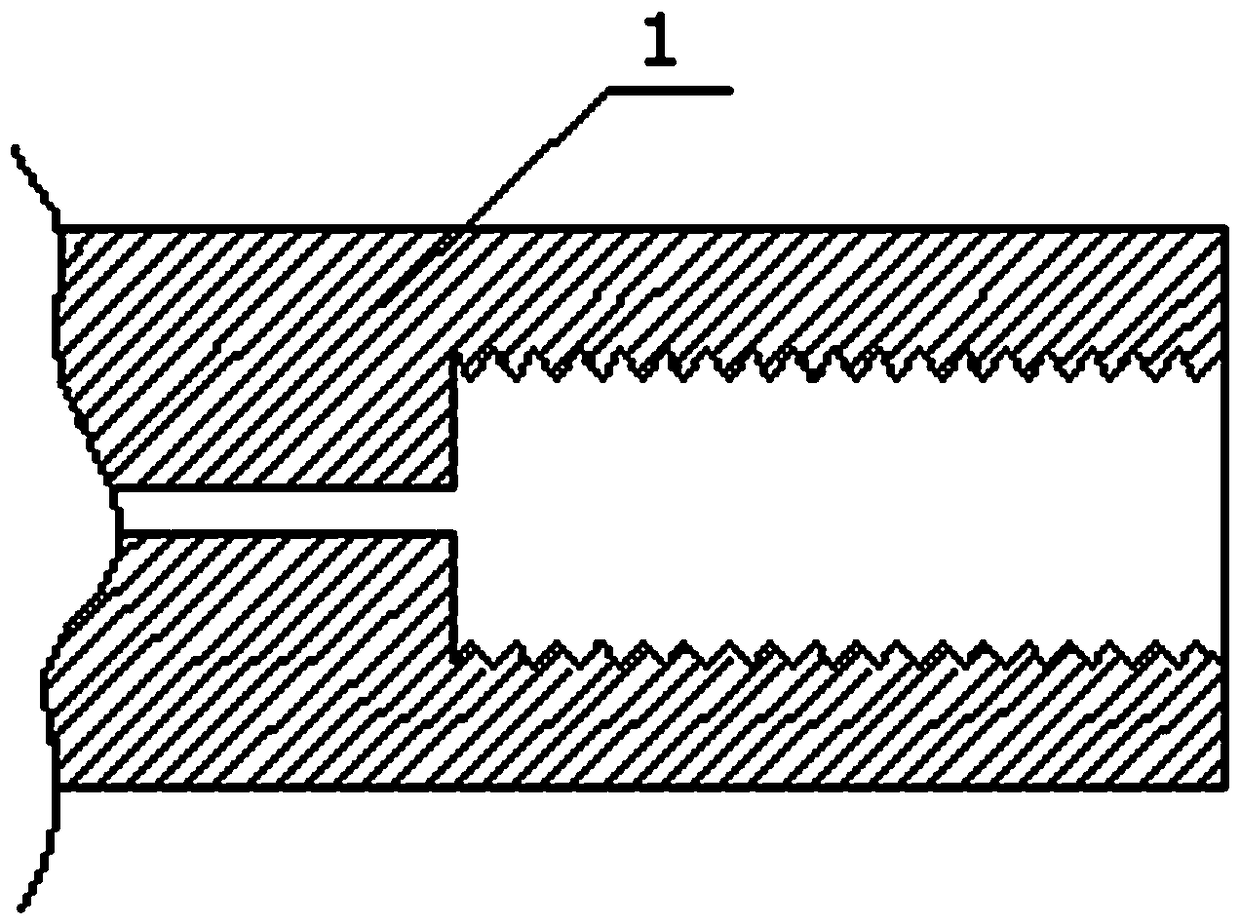

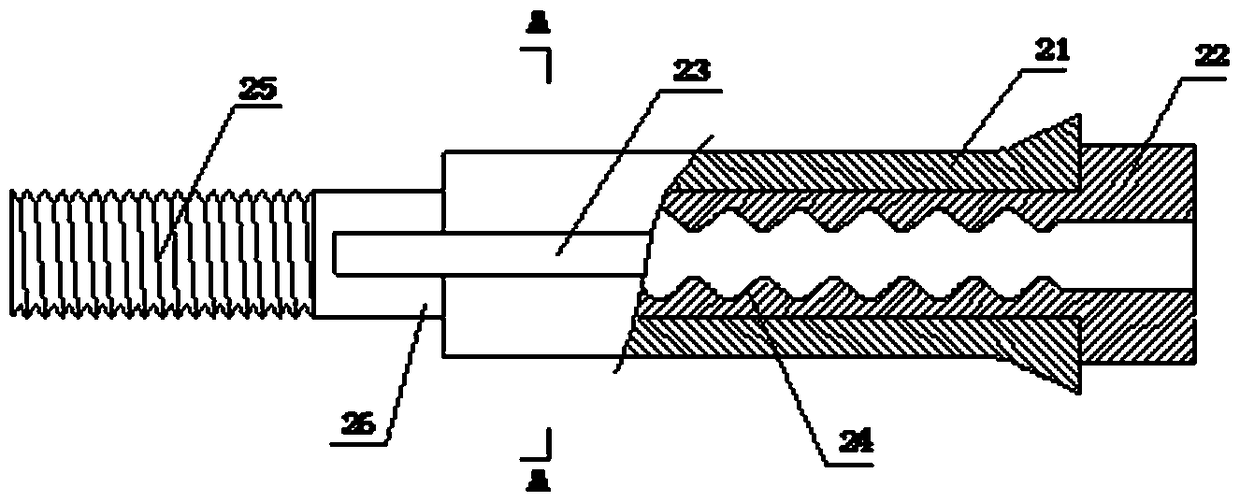

[0024] Such as figure 1 , 2 As shown, the anchor rod body 1 includes a main anchor rod body 14, an auxiliary anchor rod body 15 and a tail anchor rod body 16, and one end of the main anchor rod body 14 is used for installing an anchor rod backing plate 13, a tray 12 and a fastening nut 11, etc. The other end can be threadedly connected with the pressure grouting connector 2; there can be several auxiliary anchor rod bodies 15, and both ends are connected with the pressure grouting connector 2 through internal threads; only one end of the tail anchor rod body 16 has an int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com