Prevention and treatment method for coal seam roof separation water

A technology of coal seam roof and layer-separated water accumulation, applied in drainage, safety devices, mining equipment and other directions, can solve the problems of difficult underground construction, complex geological structure, poor control effect, etc., to ensure the ability of drainage equipment and prevent surges. Effects of water inrush accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

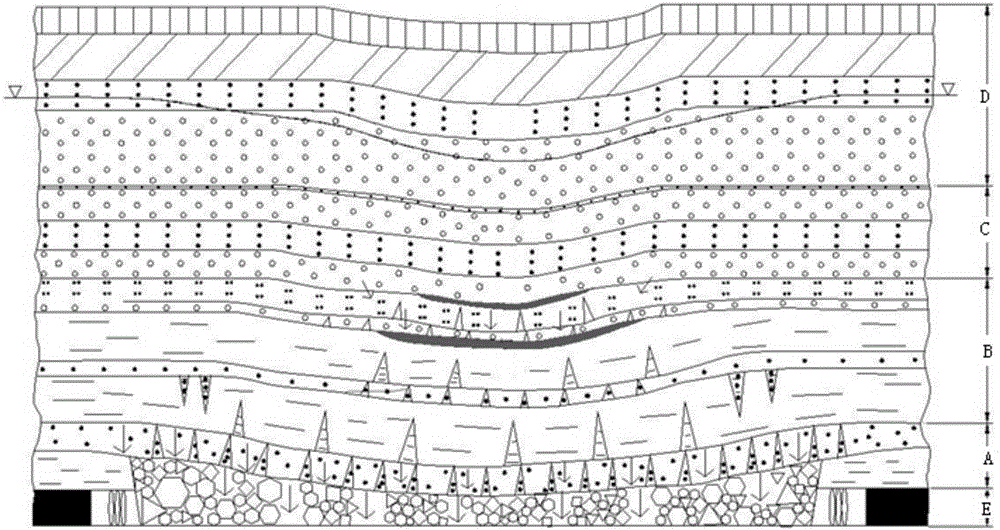

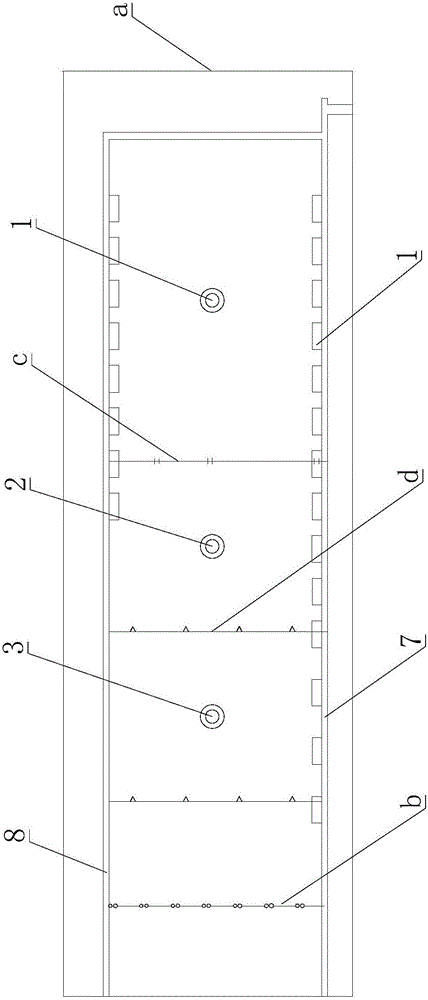

[0028] See figure 2 and image 3 The embodiment of the present invention provides a method for preventing and controlling detached water on the roof of the coal seam, which is especially suitable for the prevention and control of water damage on the roof of the coal seam under the conditions of fully mechanized caving mining of deeply buried and thick coal seams under the Cretaceous sandy conglomerate aquifer. The method mainly includes the following steps:

[0029] (1) Determine the coal mining face. After the coal mining face is determined, construct the wind lane 7 and the mechanical transport lane 8 along the mining direction on both sides of the coal mining face, and construct temporary construction in the wind lane 7 and the mechanical transport lane 8. Water tank 4, then the construction face cuts eye a.

[0030] (2) Calculate the initial closing position c of the coal seam roof abscission layer and the periodic closing position d of the abscission layer.

[0031] A...

Embodiment 2

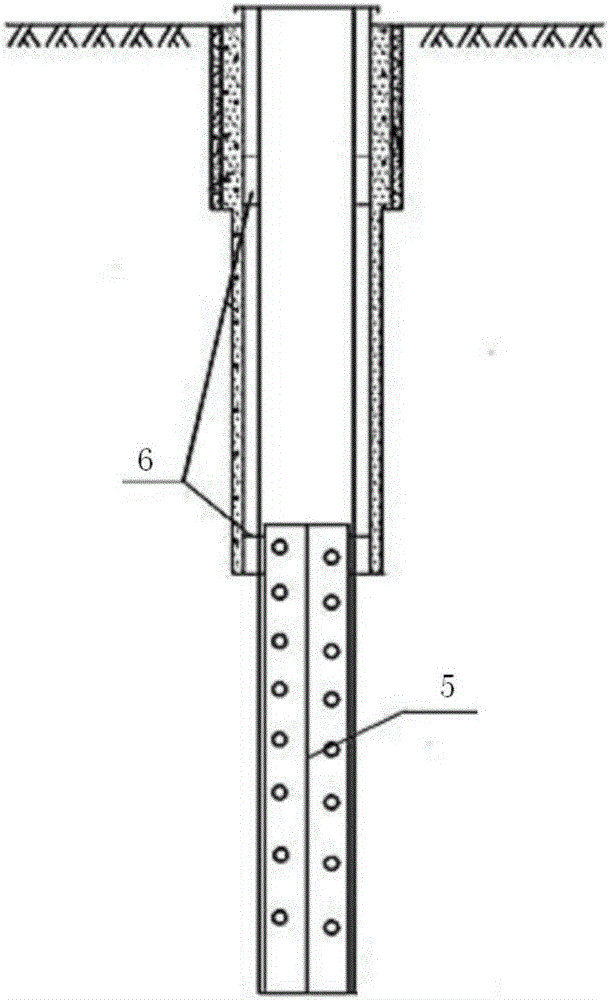

[0035] On the basis of Example 1, please refer to figure 2 , image 3 as well as Figure 4 , the ground straight-through type weep hole is divided into the first section weep hole and the second section weep hole, the diameter of the first section weep hole is greater than the diameter of the second section weep hole. Due to the great depth of the overburden of the coal seam, it is necessary to place pipes hundreds of meters downward. In order to facilitate the construction of the pipes and the processing of the holes, the holes are set as variable-diameter holes. The hole wall of the first section of the drain hole is provided with a casing 6, which has the effect of reinforcement and prevents the soil layer from blocking the through hole. The hole wall of the second section of the drain hole is provided with flower tubes 5 .

Embodiment 3

[0037] On the basis of Example 1, such as figure 2 As shown, combined with the judgment of the detachment layer development level of the coal mining face, the mechanical analysis of the duration of the abscission layer, and the dynamic mechanism analysis of the formation of the abscission water inrush channel, it is known that the distance from the cutting eye a300 to 350m of the working face is The first closed position of the abscission layer, and then the periodic breaking distance is 150-170m. With the closed position of the abscission layer, the position of the ground through-type scupper can be determined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com