Method and device for controlling output power of diesel engine

A technology of output power and diesel engine, applied in the direction of engine control, electrical control, fuel injection control, etc., can solve the problem that the diesel engine cannot work in the best stable state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

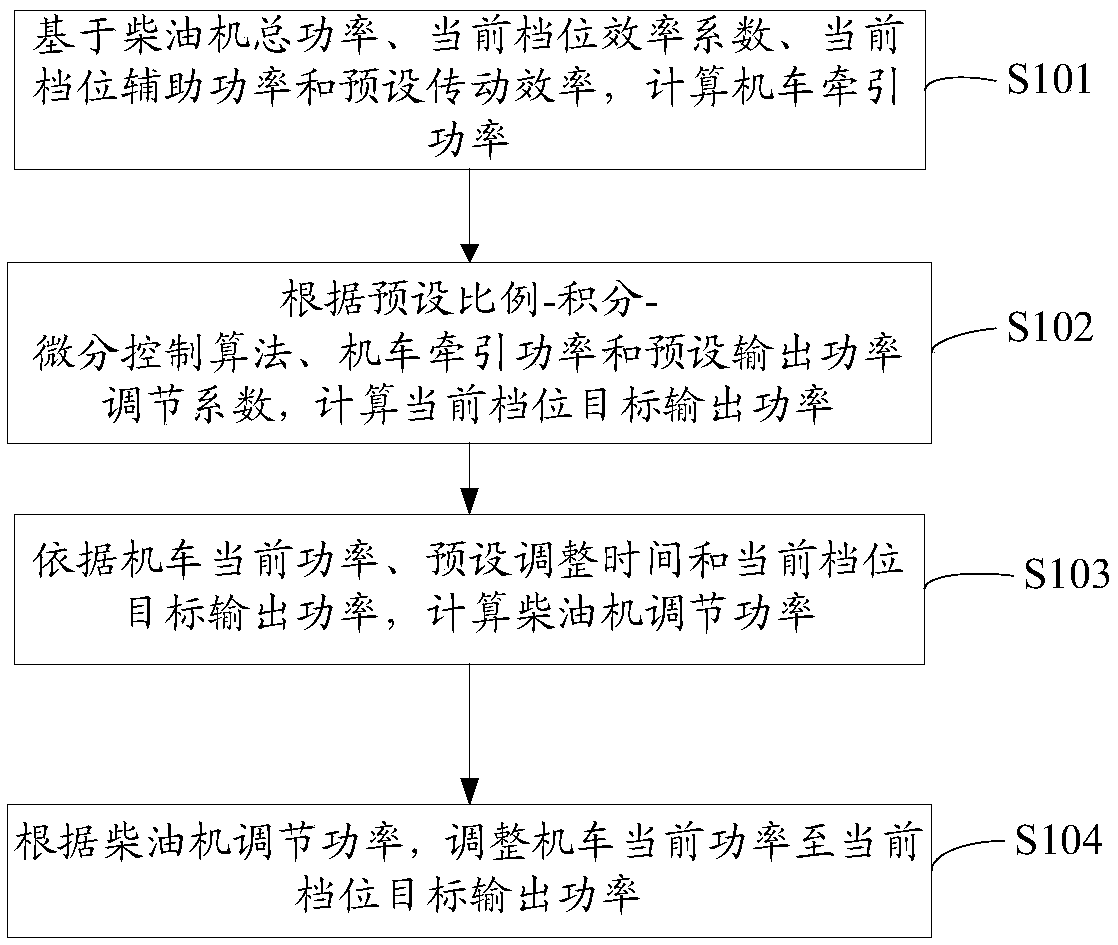

[0064] Embodiment 1 of the present invention discloses a diesel engine output power control method, the flow chart is as follows figure 1 As shown, the diesel engine output power control method includes:

[0065] S101, based on the total power P of the diesel engine, the efficiency coefficient a of the current gear, and the auxiliary power P of the current gear 1 and the preset transmission efficiency b, calculate the locomotive traction power P 2 ;

[0066] In the process of executing step S101, the position of the controller handle determines the current gear of the diesel engine, and then the efficiency coefficient of the current gear and the auxiliary power of the current gear can be determined, and then the traction of the locomotive can be calculated according to the total power of the diesel engine and the preset transmission coefficient. power;

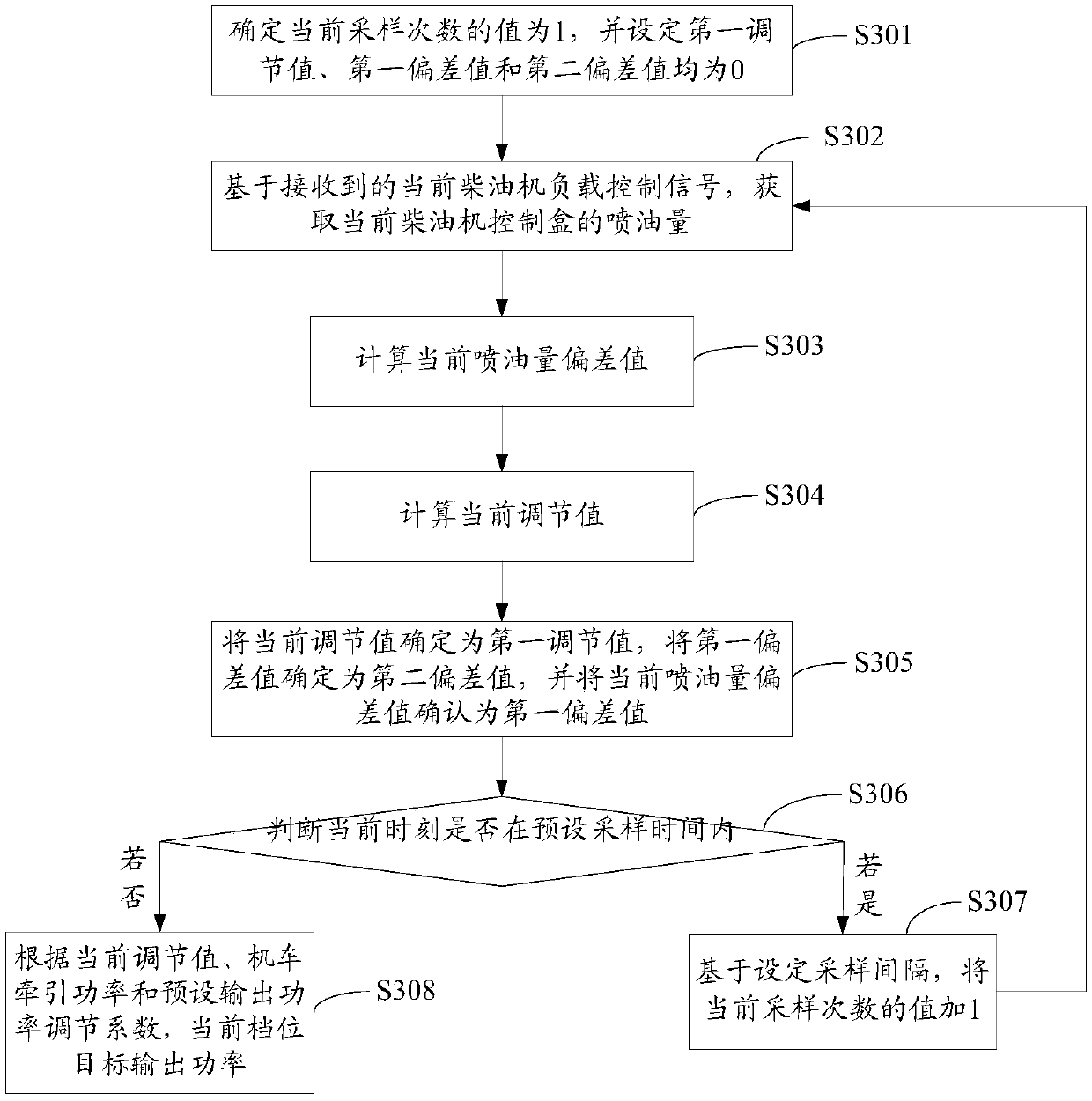

[0067] S102, according to the preset proportional-integral-derivative control algorithm, the locomotive traction power P ...

Embodiment 2

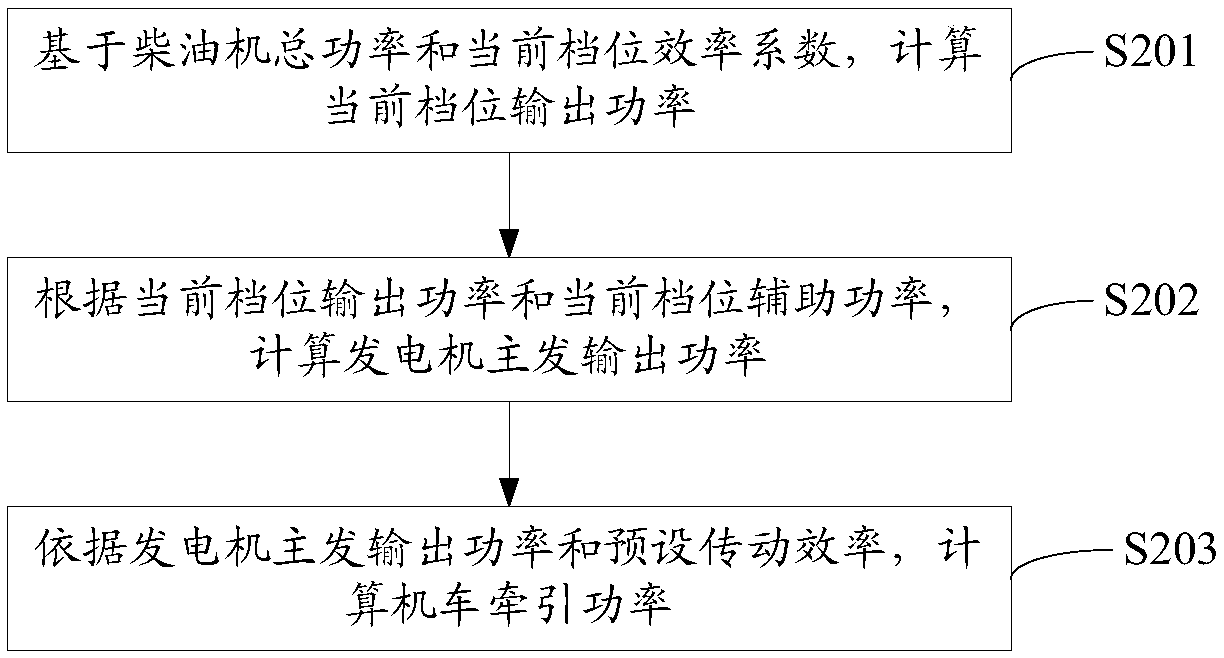

[0075] Based on the above-mentioned method for controlling the output power of a diesel engine disclosed in Embodiment 1 of the present invention, such as figure 1 In the shown step S101, based on the total power P of the diesel engine, the efficiency coefficient a of the current gear, and the auxiliary power P of the current gear 1 and the preset transmission efficiency b, calculate the locomotive traction power P 2 The specific execution process, such as figure 2 shown, including:

[0076] S201, based on the total power P of the diesel engine and the efficiency coefficient a of the current gear, calculate the output power P of the current gear 6 ;

[0077] In step S201, formula (2) is used to calculate the current gear output power P 6 :

[0078] P 6 =P*a(2);

[0079] S202, output power P according to the current gear position 6 and the current gear auxiliary power P 1 , to calculate the output power P of the main engine of the generator 7 ;

[0080] In step S202...

Embodiment 3

[0112] Based on the above-mentioned diesel engine output power control method provided by each embodiment of the present invention, the third embodiment of the present invention correspondingly discloses a diesel engine output power control device that implements the above-mentioned diesel engine output power control method, and its structural diagram is as follows Figure 5 As shown, the diesel engine output power control device 500 includes: a first calculation module 501, a second calculation module 502, a third calculation module 503 and an adjustment module 504; wherein,

[0113] The first calculation module 501 is used to calculate the total power P of the diesel engine, the efficiency coefficient a of the current gear, and the auxiliary power P of the current gear 1 and the preset transmission efficiency b, calculate the locomotive traction power P 2 ;

[0114] The second calculation module 502 is used to calculate according to the preset proportional-integral-derivati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com