A punching device suitable for pump body

A punching and pump body technology, used in drilling/drilling equipment, metal processing equipment, boring/drilling, etc., can solve the problem that the distance between the threaded drill and the pump body cannot be flexibly adjusted, and the maximum adjustment height of the set components cannot be changed. , maintenance and cleaning process are cumbersome and other problems, to achieve the effect of easy maintenance and cleaning, avoid sudden drop, and expand the use function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

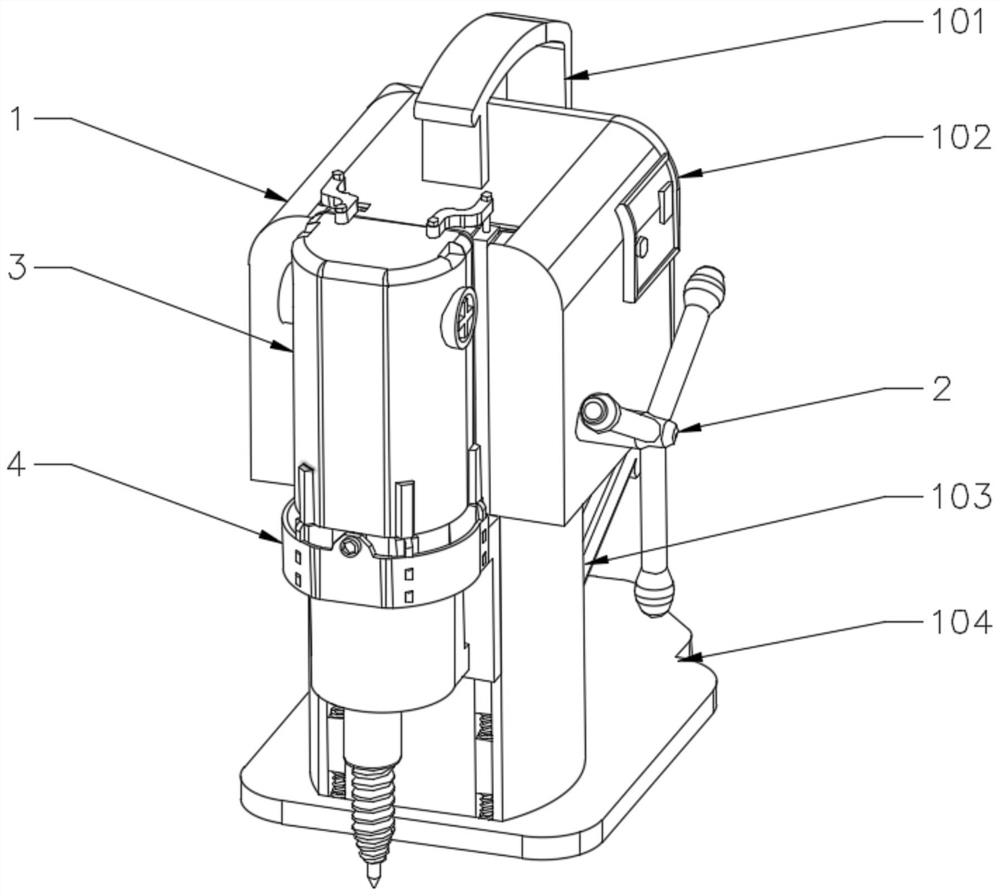

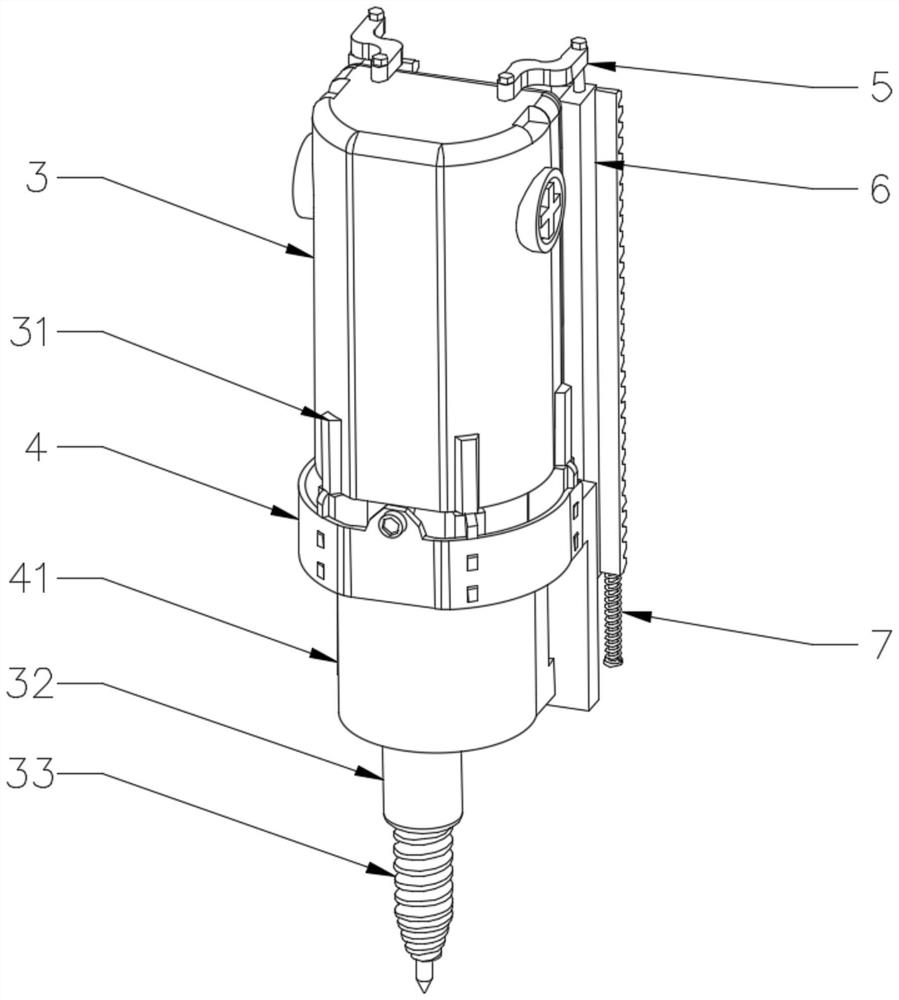

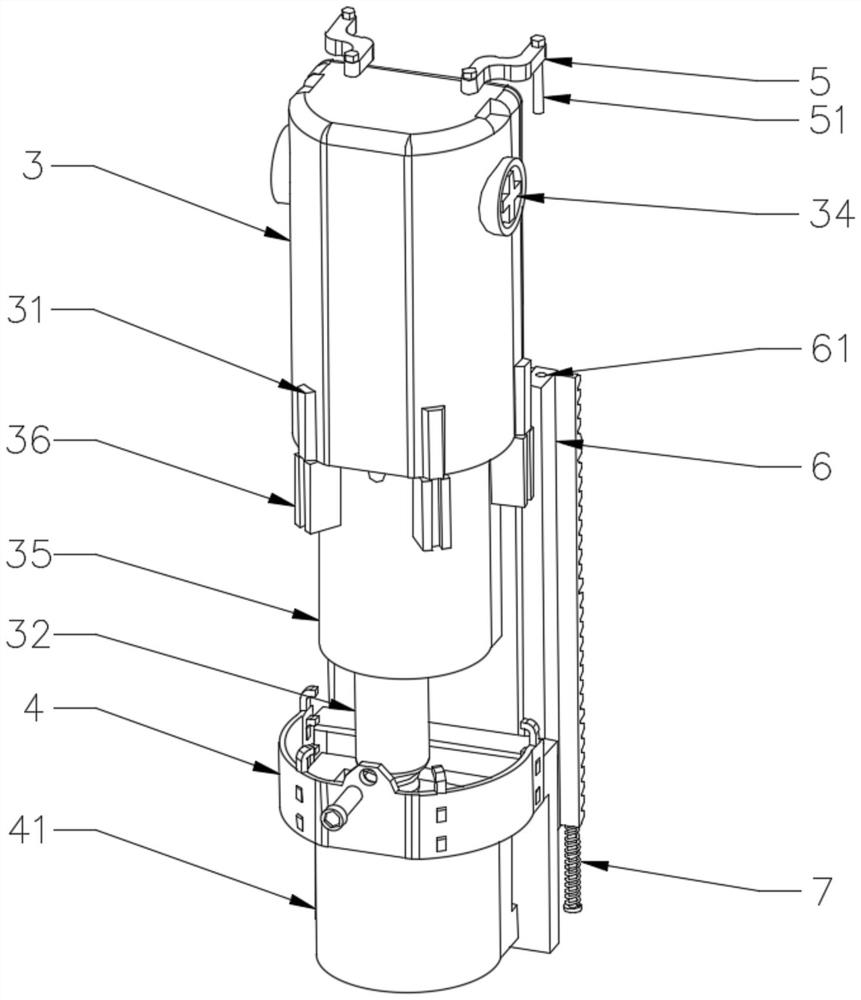

[0030] Example 1: see Figure 1-11 , the present invention provides a technical solution for punching equipment suitable for the pump body: including a punching assembly 1, one side of the punching assembly 1 is installed with a shaft 2 for rotating and adjusting the vertical height of the drilling machine 3, the punching A drilling machine 3 for providing drilling power is installed in the middle of one end of the assembly 1, one side of the drilling machine 3 and one end of the punching assembly 1 is provided with a set assembly 4 for installing the drilling machine 3, the shaft 2 One side is connected with a linkage assembly 10 for rotating linkage.

[0031] like Figure 10-11 As shown, the shaft 2 includes a screw head 21 threadedly connected to it, one side of the punching assembly 1 is provided with a rod hole 1002 corresponding to the shaft 2, and three sets of hinges are arranged around the outer surface of the shaft 2 in an equilateral triangle shape. 22. One end of...

Embodiment 2

[0033] Example 2: as Figure 1-11 As shown, it includes a punching assembly 1, one side of the punching assembly 1 is installed with a shaft 2 for rotating and adjusting the vertical height of the drilling machine 3, and one end of the punching assembly 1 is installed in the middle position for providing drilling power. The drilling machine 3 is provided with a sleeve assembly 4 for installing the drilling machine 3 on one side of the drilling machine 3 and at one end of the punching assembly 1 , and a linkage assembly 10 for rotational linkage is connected to one side of the shaft 2 .

[0034] like Figure 2-5 As shown, the sleeve assembly 4 includes an inner cavity cylinder 41 for docking the sleeve power regulator 35, wherein the power regulator 35 is used to adjust the output power of the drilling machine 3, and a convex wall is fixed in the middle of one end of the inner cavity cylinder 41 42, its surface is provided with bolt holes, one end of the convex wall 42 and the...

Embodiment 3

[0037] Example 3: as Figure 1-11 As shown, it includes a punching assembly 1, one side of the punching assembly 1 is installed with a shaft 2 for rotating and adjusting the vertical height of the drilling machine 3, and one end of the punching assembly 1 is installed in the middle position for providing drilling power. The drilling machine 3 is provided with a sleeve assembly 4 for installing the drilling machine 3 on one side of the drilling machine 3 and at one end of the punching assembly 1 , and a linkage assembly 10 for rotational linkage is connected to one side of the shaft 2 .

[0038] like Figure 1-9 As shown, the inner side of the T-shaped groove 105 is installed with a first pressure block 8 for supporting and buffering, the lower end of the first pressure block 8 is connected with three sets of elastic rod assemblies 1 81 on both sides, and the lower end of the first pressure block 8 passes through the elastic rod. The component one 81 is provided with a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com