Streamlined valve core of electric EGR valve

An EGR valve, streamlined technology, used in engine components, machines/engines, exhaust gas recirculation, etc., can solve the problems of increased valve core impact force, high cost, and large improvement workload, and achieves weakening of the reverse force, The effect of reducing the dependence of motor torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

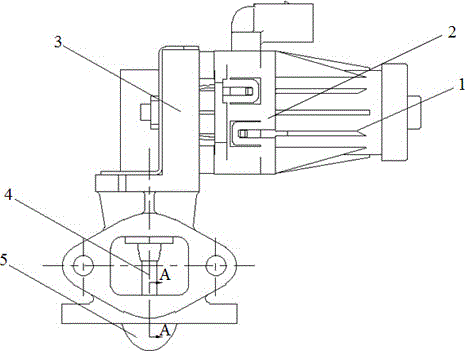

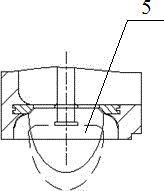

[0013] A streamlined electric EGR valve spool, its structure is as follows figure 2 As shown, it includes a straight part and an elliptical part. The top of the elliptical part is transitionally connected with the edge of the straight part; Fixed connection; the ellipse part is connected in the air inlet of the exhaust chamber.

[0014] The structure of the present invention applied in the electric EGR valve is as follows figure 1 As shown, the motor 1 is connected to the gearbox mechanism 2 through gears, and an angle sensor is also provided in the gearbox 2 to monitor the angle change of the output of the gearbox 2, that is, the opening of the EGR valve; the gearbox 2 and the motor 1 are combined into a A whole is installed on the top of the valve seat 3, the gearbox 2 is connected to the center rod 4 through the eccentric wheel,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com