Small wind turbine blade wing section suitable for low Reynolds number flowing

A wind turbine blade and airfoil technology is applied in the field of small wind turbine blade airfoils, which can solve the problems of low wind energy utilization efficiency of small wind turbines, and achieve the effect of improving the low wind energy utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

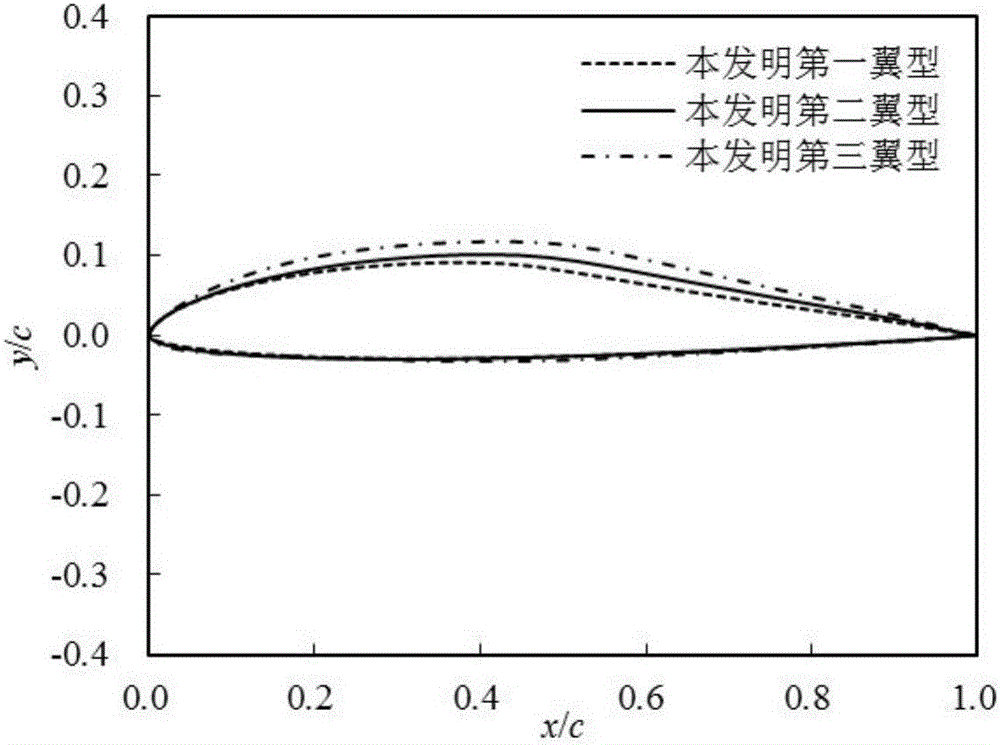

[0020] The maximum thickness of the first airfoil of the present invention is 12% of the chord length, the distance between the maximum thickness point and the leading edge is 35.9% of the chord length, the maximum camber is 3.1% of the chord length, and the distance between the maximum camber point and the leading edge is chord length 36.0% longer.

[0021] The dimensionless two-dimensional coordinates of the upper airfoil and the lower airfoil of the first airfoil of the present invention are respectively shown in Table 1a and Table 1b.

[0022] Table 1a Upper airfoil of the first airfoil

[0023]

[0024]

[0025] Among them, the x / c value indicates the position of a point on the airfoil surface relative to the leading edge in the direction of the chord line, and the y / c value indicates the height from the chord line to a certain point on the airfoil curve.

[0026] Table 1b Lower airfoil of the first airfoil

[0027] serial number

x / c

y / c

seria...

Embodiment 2

[0031] The maximum thickness of the second airfoil of the present invention is 13% of the chord length, the distance between the maximum thickness point and the leading edge is 38.0% of the chord length, the maximum camber is 3.6% of the chord length, and the distance between the maximum camber point and the leading edge is chord length 41.4% longer.

[0032] The dimensionless two-dimensional coordinates of the upper airfoil and the lower airfoil of the second airfoil of the present invention are respectively shown in Table 2a and Table 2b.

[0033] Table 2a Upper airfoil of the second airfoil

[0034] serial number

x / c

y / c

serial number

x / c

y / c

serial number

x / c

y / c

1

0

0

21

0.17491

0.07859

41

0.85931

0.02818

2

0.0001

0.00055

22

0.2092

0.08505

42

0.89353

0.02173

3

0.00024

0.00131

23

0.24335

0.09016

43

0.92402

0.01557

4

0.00044

0.00238...

Embodiment 3

[0041] The cross-section airfoil maximum thickness of the third airfoil of the present invention is 15% of the chord length, the distance between the maximum thickness and the leading edge is 40.7% of the chord length, the maximum camber is 4.3% of the chord length, and the maximum camber and the front edge are 40.7% of the chord length. The edge distance is 44.3% of the chord length.

[0042] The dimensionless two-dimensional coordinates of the upper airfoil and the lower airfoil of the third airfoil of the present invention are respectively shown in Table 3a and Table 3b.

[0043] Table 3a Upper airfoil of the third airfoil

[0044]

[0045]

[0046] Table 3b The lower airfoil of the third airfoil

[0047] serial number

x / c

y / c

serial number

x / c

y / c

serial number

x / c

y / c

1

0

0

21

0.18711

-0.02685

41

0.86671

-0.01055

2

0.00011

-0.0011

22

0.2238

-0.02847

42

0.89913

-0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com