Discharge device

A technology of unloading device and unloading valve, which is applied to valve device, lift valve, safety valve, etc., can solve the problems of frequent maintenance, parking, and easy-to-failure systems, and achieve a simple and compact structure, ensure effective reset, and reduce weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

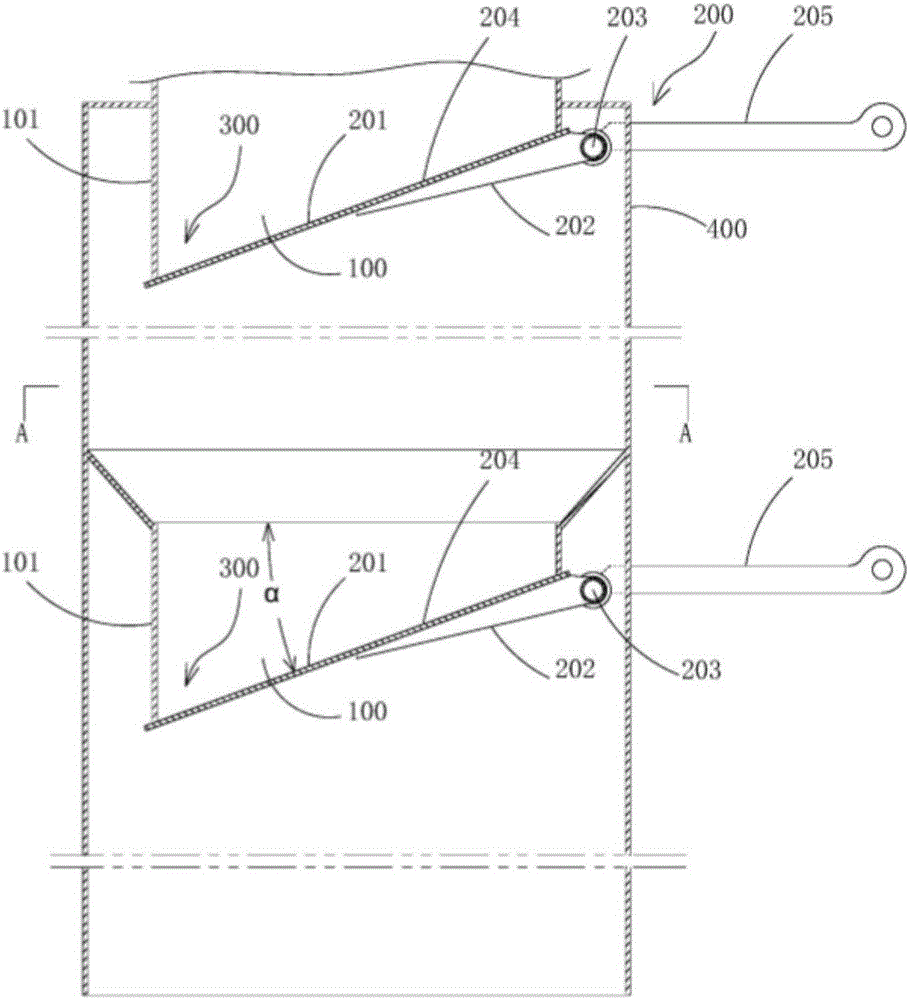

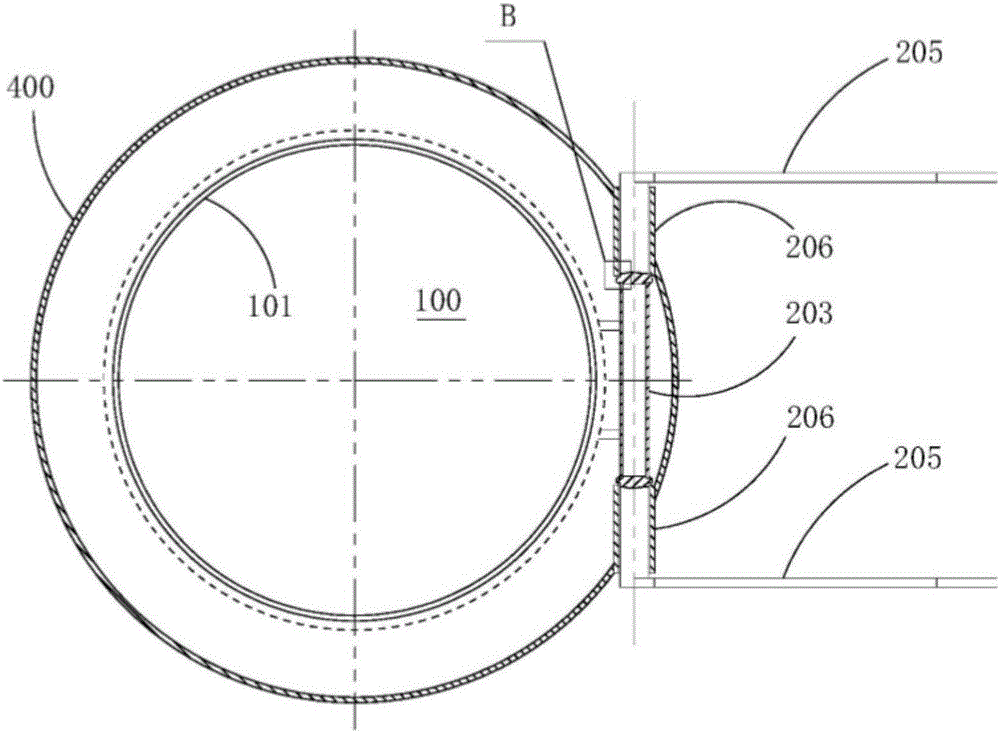

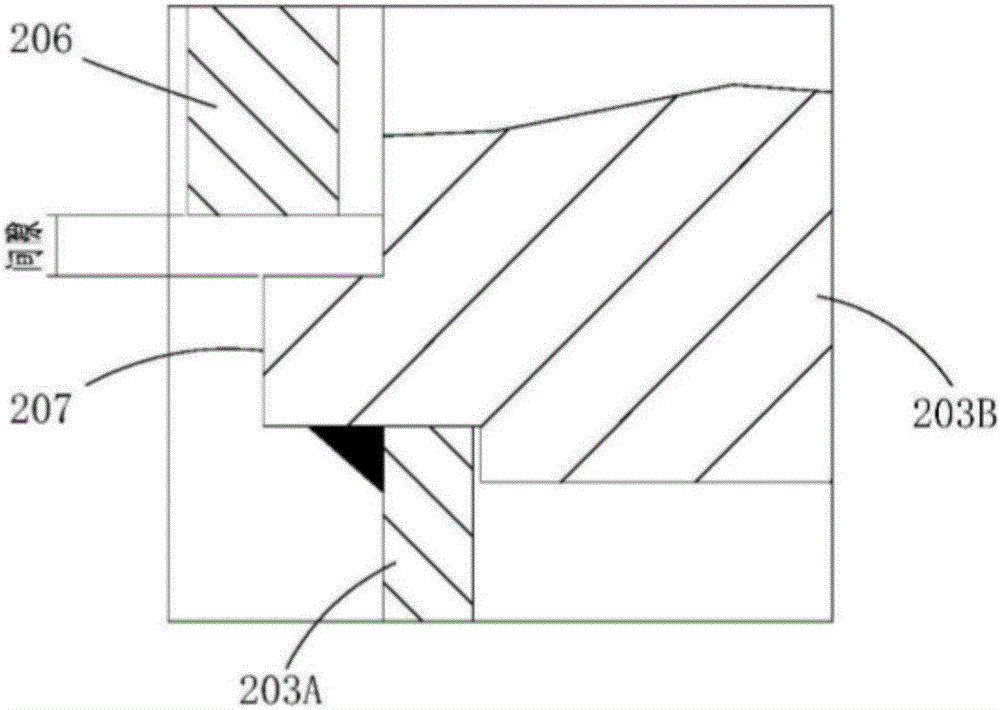

[0010] Such as figure 1 , 2 As shown, the unloading device includes a cylinder 400, and at least one unloading assembly is arranged in the cylinder 400, and the unloading assembly includes an inner tube 101 located in the cylinder 400 and a lower nozzle of the inner tube 101 It is an automatic discharge valve for the discharge valve port 100, the automatic discharge valve includes a beveled discharge valve port 100 and is located below the discharge valve port 100, cooperates with the discharge valve port 100 and is formed by The sealing inclined valve plate 201 held by a set of self-resetting lever mechanism 200, the material accumulation angle 300 is formed between the low end of the sealing inclined valve plate 201 and the side wall of the discharge valve port 100, and the self-resetting lever mechanism has A fulcrum shaft 203 and a force arm 204 and a balance arm 205 connected to the fulcrum shaft 203 and located on both sides of the fulcrum shaft 203 respectively. Adapt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com