Ball valve metal valve seat mounting structure with protective structure

A technology of protection structure and installation structure, which is applied in the direction of valve devices, cocks including cut-off devices, engine components, etc. It can solve the problems that valves cannot be opened and closed, damage valve stems, valve torque increases, etc., and achieve safe and reliable production and operation. , improve the service life, and ensure the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

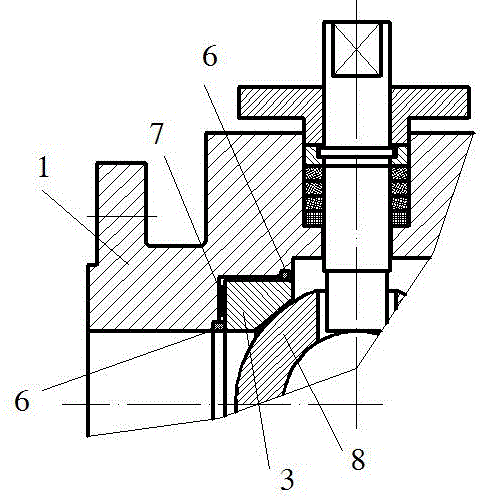

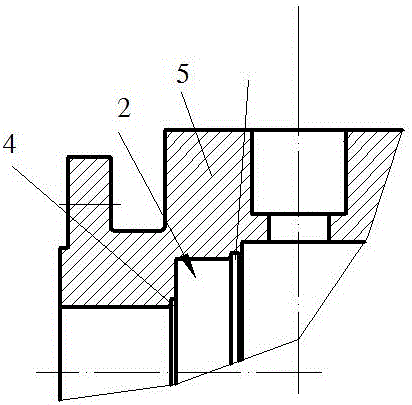

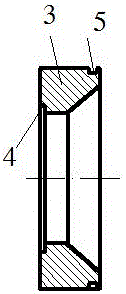

[0015] Embodiment 1: A metal valve seat installation structure of a ball valve with a protective structure, including a valve body 1, a metal valve seat hole 2 is opened in the center of the valve body 1, a metal valve seat 3 is installed in the metal valve seat hole 2, and a metal valve seat The first sealing groove 4 is provided on the horizontal connection end surface between the hole 2 and the metal valve seat 3, and the second sealing groove 5 is provided on the contact surface between the metal valve seat hole 2 and the side wall of the metal valve seat 3. A sealing ring 6 is arranged in the groove (4, 5), a wave spring 7 is arranged between the horizontal surface of the metal valve seat 3 and the horizontal end surface of the metal valve seat hole 2, and the spherical surface of the ball core 8 in the valve body 1 cooperates with the metal valve seat 3 for pre-tightening . The wave spring 7 is bent from stainless steel.

Embodiment 2

[0016] Embodiment 2: A metal valve seat installation structure of a ball valve with a protective structure, including a valve body 1, a metal valve seat hole 2 is opened in the center of the valve body 1, a metal valve seat 3 is installed in the metal valve seat hole 2, and the metal valve seat 3 There is a first sealing groove 4 on the horizontal end surface, a second sealing groove 5 is opened on the side wall of the metal valve seat 3, a sealing ring 6 is arranged in the first and second sealing grooves (4, 5), and the metal valve seat 3 A wave spring 7 is arranged between the horizontal surface and the horizontal end surface of the metal valve seat hole 2, and the spherical surface of the ball core 8 in the valve body 1 cooperates with the metal valve seat 3 for pre-tightening. The wave spring 7 is bent from stainless steel. The wave spring 7 is arranged in the gap between the first and second sealing grooves (4, 5).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com