Two-stage gas pressure reducing valve

A pressure reducing valve and gas technology, which is applied in safety valves, balance valves, valve devices, etc., can solve the problems of outlet pressure accuracy and stability, which have great influence on manufacturing accuracy, and achieve stable sealing, long service life and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the technical scheme of the patent of the present invention is described further.

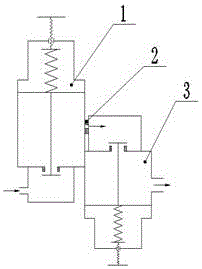

[0024] exist figure 1 Middle: The first-stage pressure reducing valve 1 on the left is installed upright, and the second-stage pressure-reducing valve 3 on the right is reverse-installed.

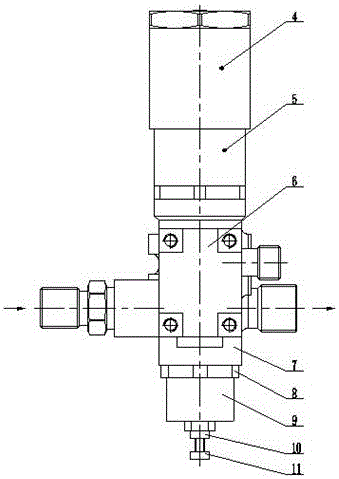

[0025] exist figure 2 Middle: High-pressure gas flows in from the lower end of the primary valve body 6 on the left, and flows out from the middle of the secondary valve body 7 on the right after two times of decompression and pressure stabilization. The outlet diameter is larger than the inlet diameter.

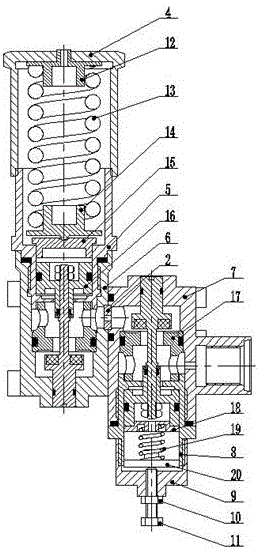

[0026] exist image 3 Middle: The valve assembly 16 and the throttle valve seat 17 are installed in the cavity of the primary valve body 6, the upper end is connected with the primary valve cover 5, the upper end of the primary valve cover 5 is connected with the primary adjusting nut 4, the upper cavity of the primary valve cover 5 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com